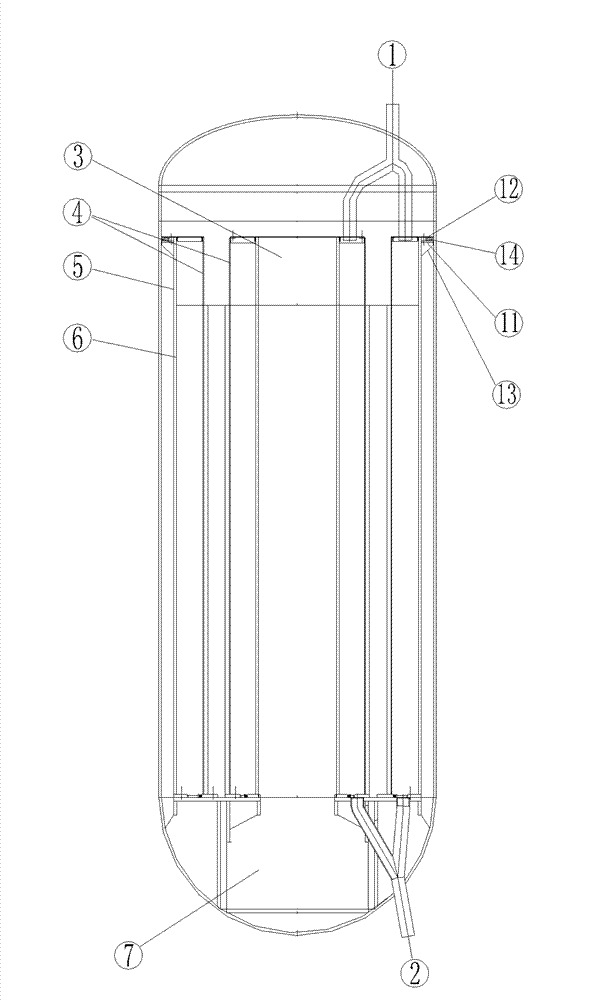

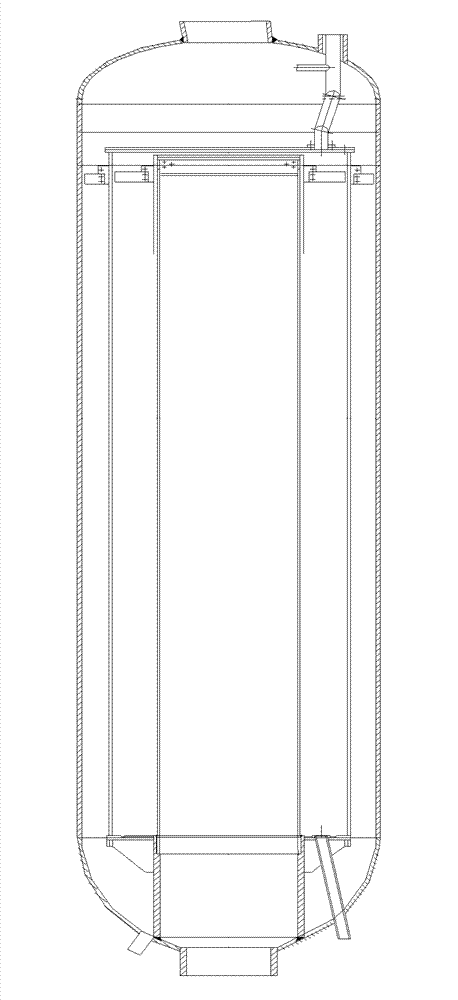

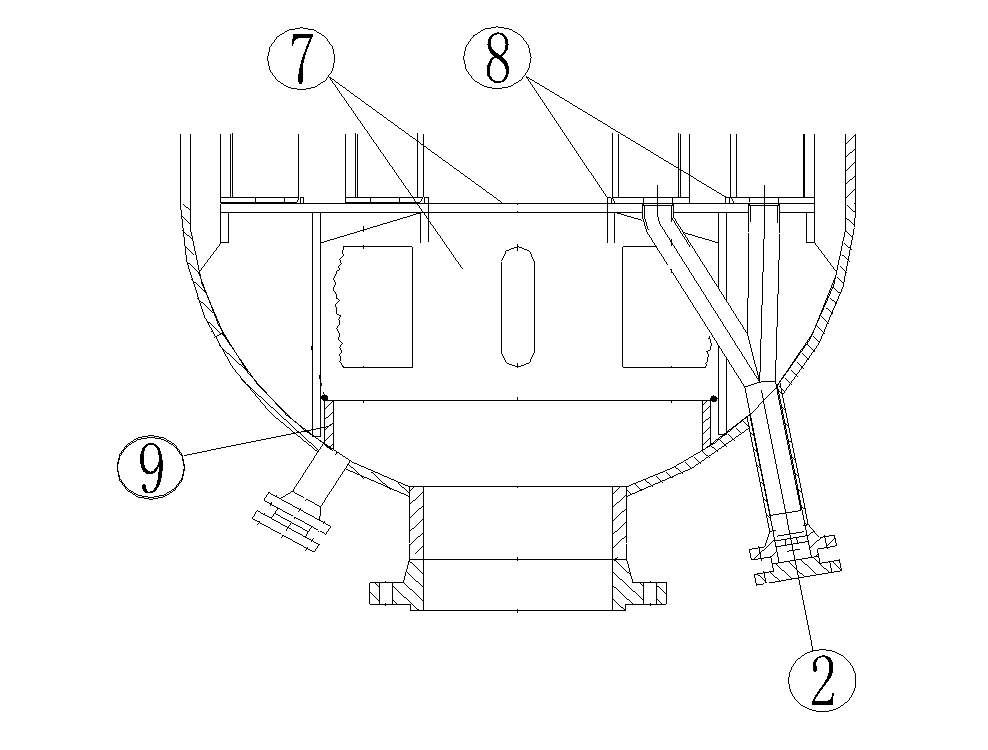

Radial reactor

A technology for reactors and reactor shells, applied in the field of radial catalytic reactors, which can solve the problems of small contact area, large bed thickness, conversion rate, selectivity, and adverse effects of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]The following description of preferred embodiments of the invention is merely exemplary in nature and is not intended to limit the invention, its application or uses. It should be noted that although the preferred embodiment discloses various specific structures and connection relationships of the present invention, those skilled in the art will easily understand that the protection scope of the present invention is not limited to these structures and connection relationships, without departing from the present invention Under the condition of the basic principles of the invention, those skilled in the art can make modifications, adjustments or equivalent replacements to these structures and connection relationships. For example, although the technical scheme of the present invention is described in conjunction with the Z-type flow radial catalytic reactor in the following preferred embodiments, those skilled in the art will easily understand that the Z-type flow radial c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com