A nickel-iron precision alloy welding wire

A technology of precision alloy and welding wire, applied in the welding field of nickel-iron precision alloy welding wire and nickel-iron series precision alloy material, can solve the problem of not considering material applicability, etc., and achieve good welding process performance, high tensile strength, ideal toughness and the effect of swelling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment.

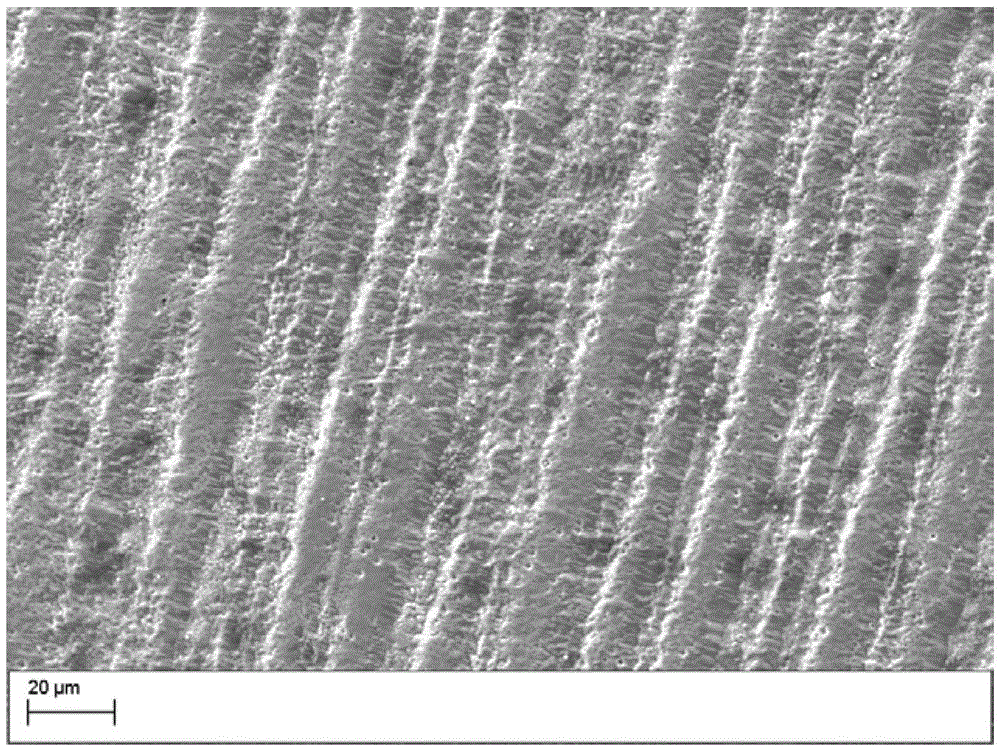

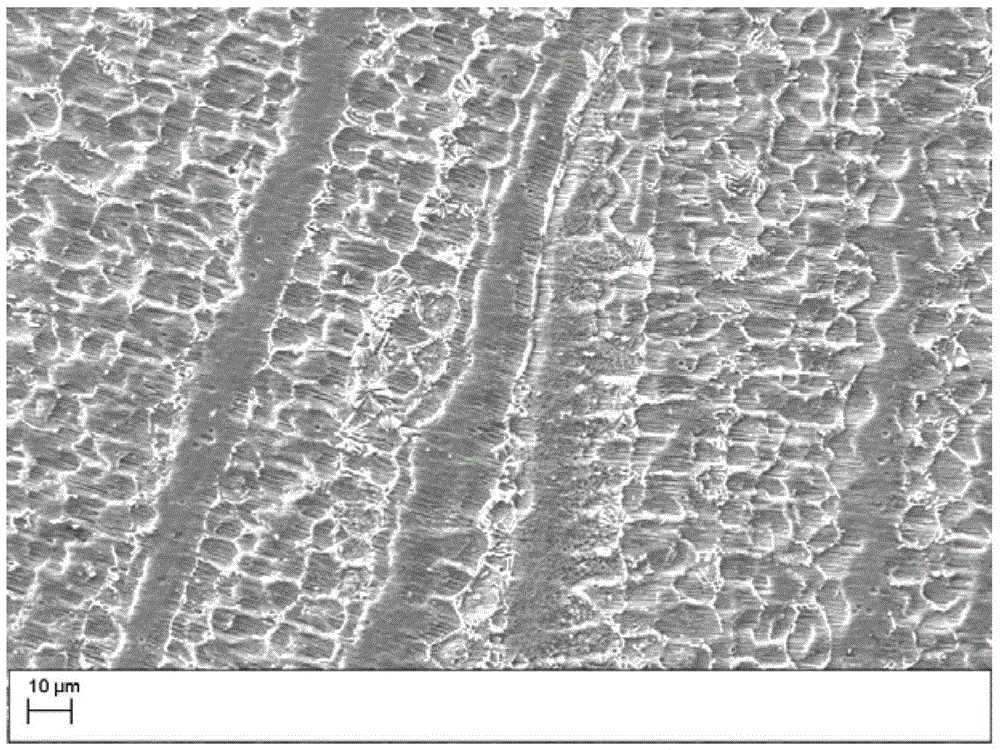

[0029] According to the composition range proposed by the present invention, 5 kinds of nickel-based alloy welding wires were manufactured through processes such as smelting, rolling, drawing, etc., the composition of which is shown in Table 2, and the diameter of the welding wire is 1.2mm.

[0030] The performance test of deposited metal is carried out by the method of metal arc shielded welding. The welding shielding gas is 80% Ar+20% He, the gas flow rate is 20L / min, the welding current is 240-260A, the welding voltage is 27-29V, and the welding speed is 300mm / min. min, the interlayer temperature was controlled to be ≤120°C, and the obtained deposited metal was heated to 840°C for 1 hour and then quenched in water. The corresponding properties of the deposited metal were shown in Table 3. Among them, after the linear expansion coefficient measurement sample is machined, it is also...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com