Wood-plastic dustless automatic feeding device

An automatic feeding and wood-plastic technology, which is applied in the field of wood-plastic dust-free automatic feeding devices, can solve the problems of unsatisfactory demand and low degree of automation, and achieve the effects of protecting materials and the environment, working safely and reliably, and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

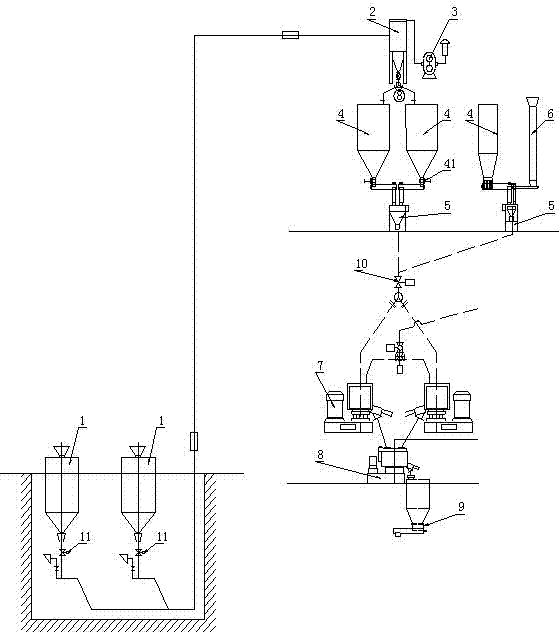

[0027] Such as figure 1 As shown, the wood-plastic dust-free automatic feeding device of the present invention includes an underground powder bucket 1, a filter 2, a first intermediate bucket 4, a powder scale 5, a high-speed mixer 7, an agitator 8, and a second intermediate bucket 9, Two underground powder barrels 1 connected in parallel are respectively connected to the inlets of the filter 2 through pipelines, and the outlet of the filter 2 is connected to two first intermediate barrels 4 connected in parallel;

[0028] Filter 2 is connected to blower 3;

[0029] Two first intermediate barrels 4 are set on the powder scale 5;

[0030] The powder scale 5 is respectively connected to two high-speed mixers 7 through the three-way gravity stop branch valve 10, and the two high-speed mixers 7 are jointly connected to the inlet of the mixer 8, and the outlet of the mixer 8 is connected to the second intermediate barrel 9;

[0031] The underground powder bucket 1 is set below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com