Intensive type storage system

A warehousing system and intensive technology, applied in the field of new three-dimensional warehouse system, can solve the problems of affecting work efficiency, low degree of automation, increasing warehouse investment, etc., and achieve the effect of reducing operating costs, simple charging procedures, and increasing storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

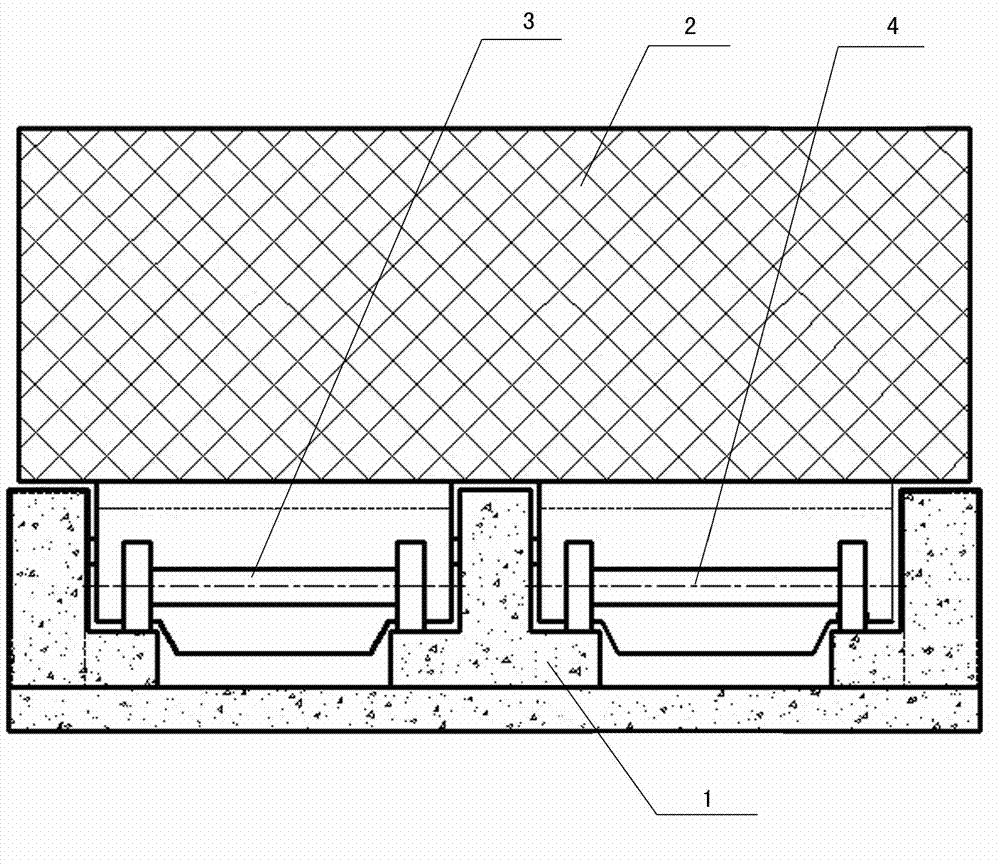

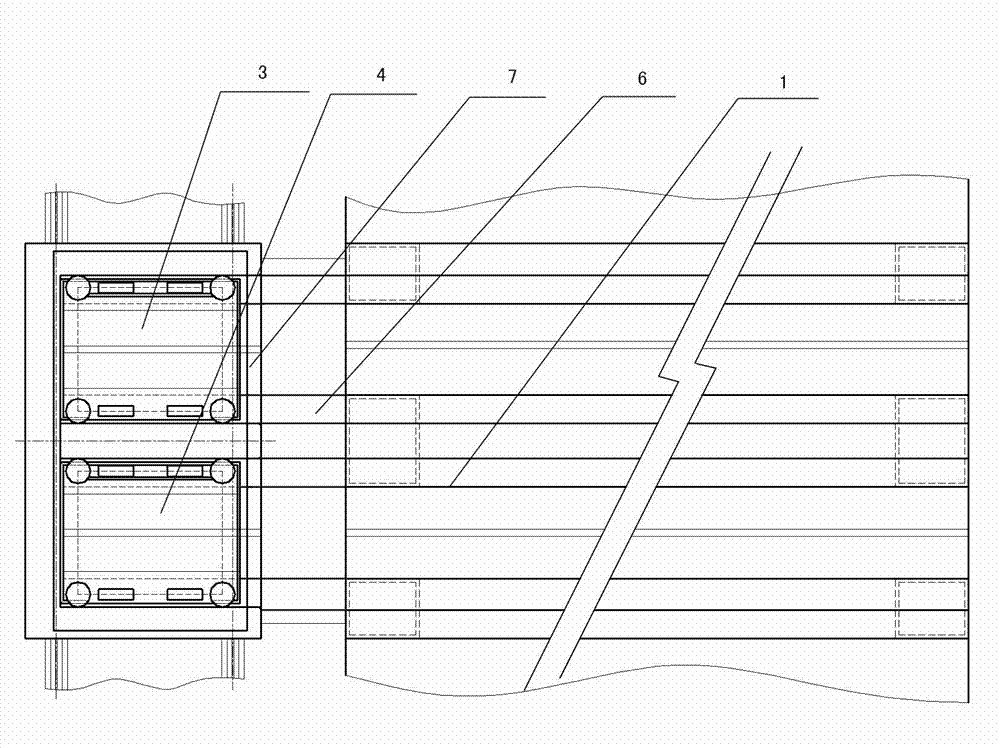

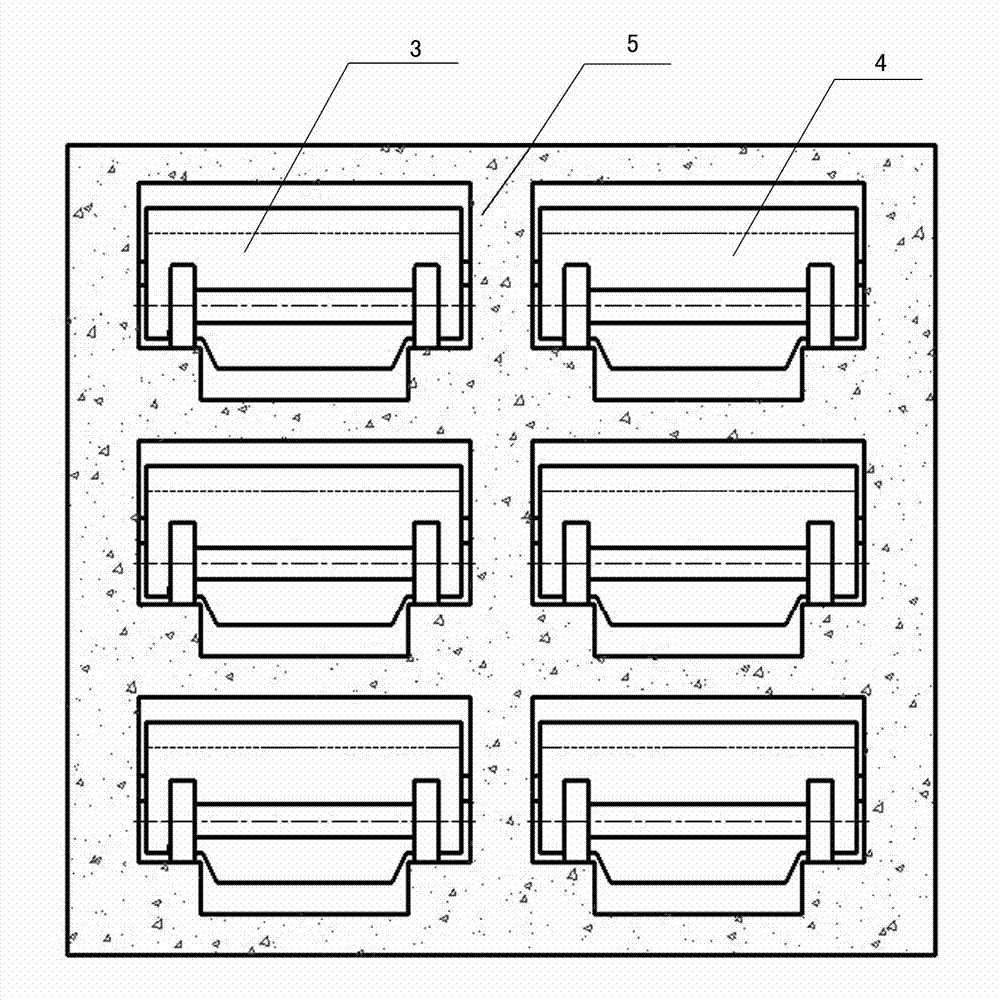

[0016] according to figure 1 , figure 2 , image 3 , Figure 4 As shown, an intensive storage system of the present invention includes a multi-point support shelf module, a mother-child shuttle vehicle module, a mother-child shuttle vehicle delivery platform module, a mother-child car automatic charging module and an automatic stacking module.

[0017] The multi-point support shelf module of the present invention is a shelf that can store large goods without using pallets and relying on shelf support. The support points of the multi-point support shelf 1 are not less than two, and the multi-point support shelf module The height of the single-layer shelf is determined according to the height of the container 2. This shelf uses more than two fulcrums to support the box body, and the shuttle car is used to transport every two support points, which solves the problem of large-sized carton collapse and saves The pallets used by the two supporting point shelves are reduced, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com