Large-tonnage duct piece vacuum suspender

A vacuum spreader, large tonnage technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of product surface scratches, affecting product appearance quality, etc., to achieve large lifting weight, large breaking force, and suction reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

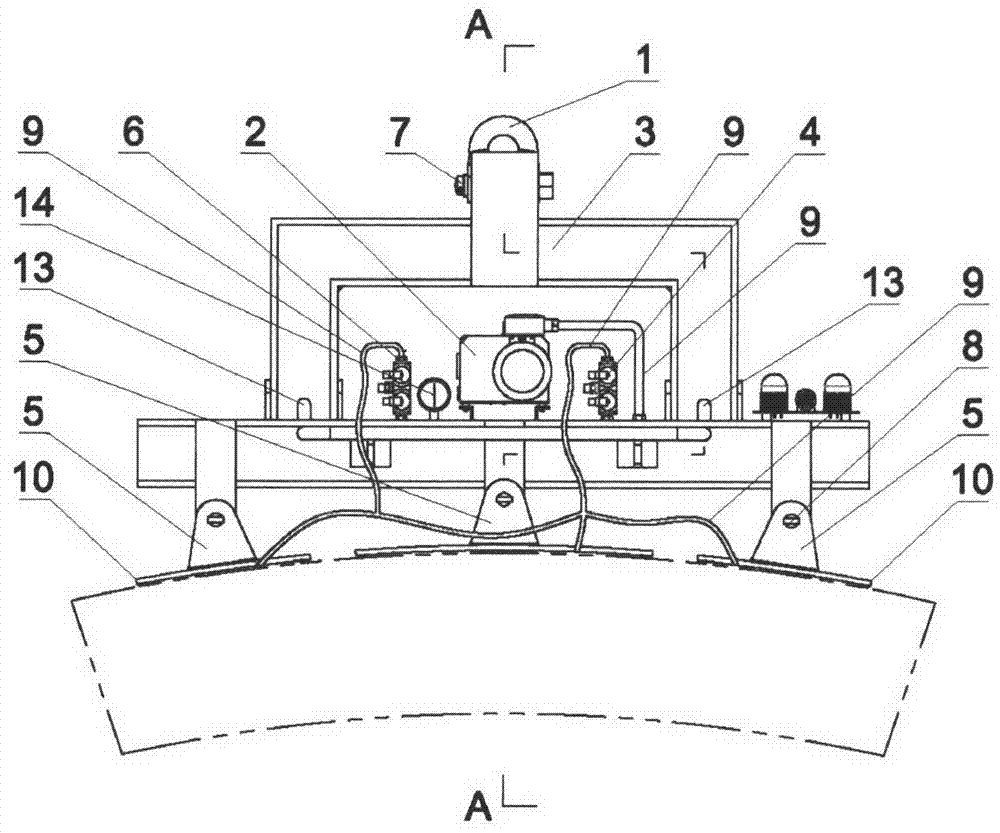

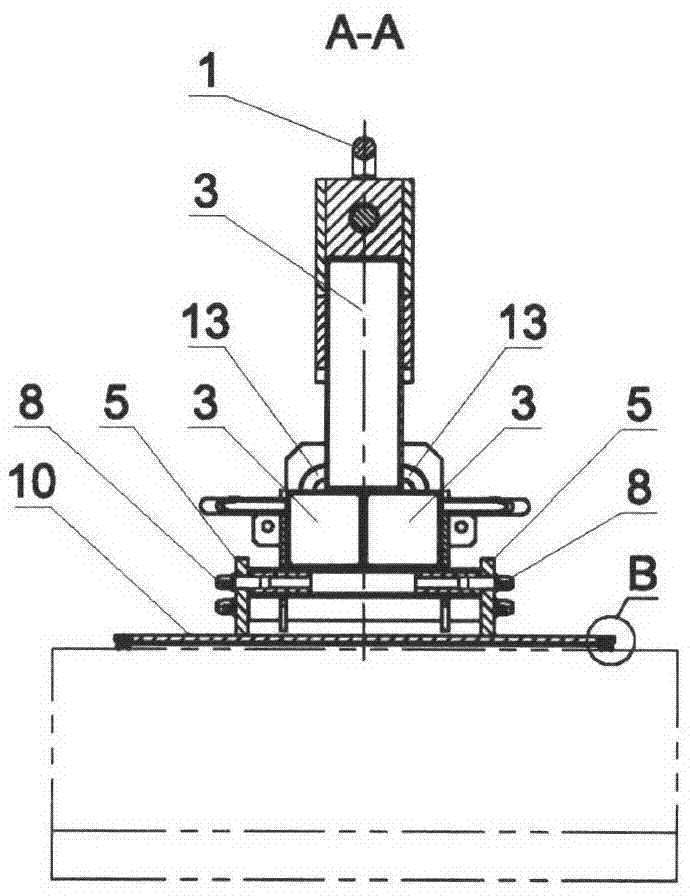

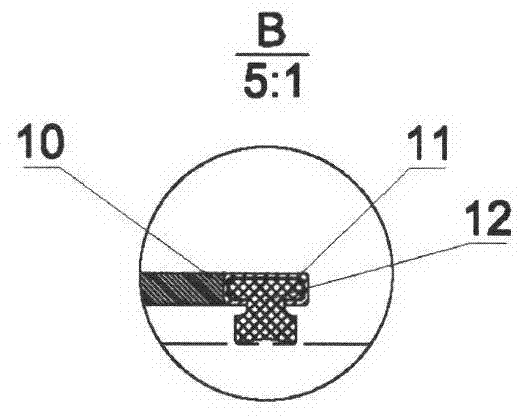

[0014] like figure 1 , figure 2 and image 3 As shown, a large-tonnage segment vacuum lifter of the present invention includes a hook 1, a vacuum pump assembly 2, a vacuum chamber 3, a suction solenoid valve 4, a deflation solenoid valve 6, a suction cup lifting lug 5, a suction cup 10, a rubber The sealing ring 12, the hook 1 is connected to the top of the vacuum chamber 3 through the pin 7, the vacuum chamber 3 is a hollow structure, the vacuum pump assembly 2 communicates with the vacuum chamber 3 through the high-pressure air pipe 9, and the suction solenoid valve 4 One end of the valve is connected to the vacuum chamber 3, and the other end is connected to the internal space of the suction cup 10 through the high-pressure air pipe 9. One end of the deflation solenoid valve 6 is connected to the internal space of the suction cup 10 through the high-pressure air pipe 9, and the other end is communicated with the atmosphere. The suction cup 10 is fixed on the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com