Etching and roasting equipment

A baking equipment and equipment technology, applied in the direction of chemically reactive gases, crystal growth, electrical components, etc., can solve problems affecting temperature control, surface particles, long baking time, and inability to etch epitaxial substrates. To achieve the effect of ensuring normal heating and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiment and accompanying drawing, set forth more details in the following description so as to fully understand the present invention, but the present invention can obviously be implemented in many other ways different from this description, Those skilled in the art can make similar promotions and deductions based on actual application situations without violating the connotation of the present invention, so the content of this specific embodiment should not limit the protection scope of the present invention.

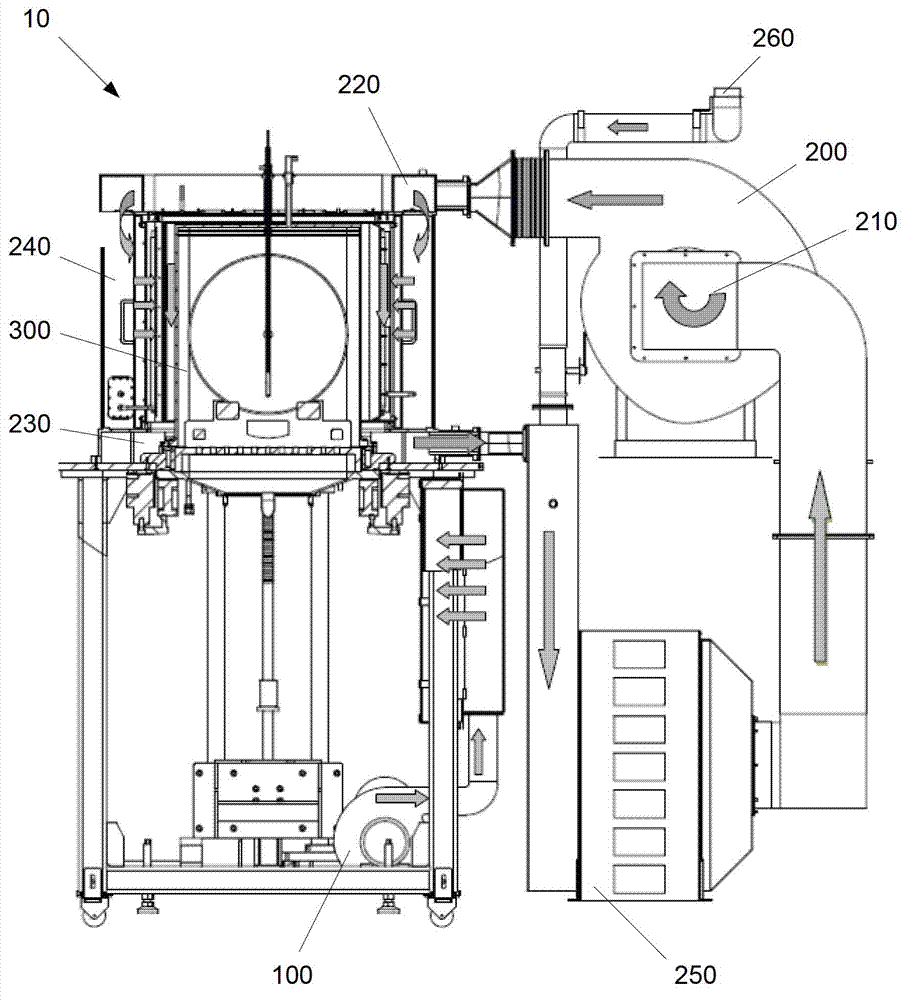

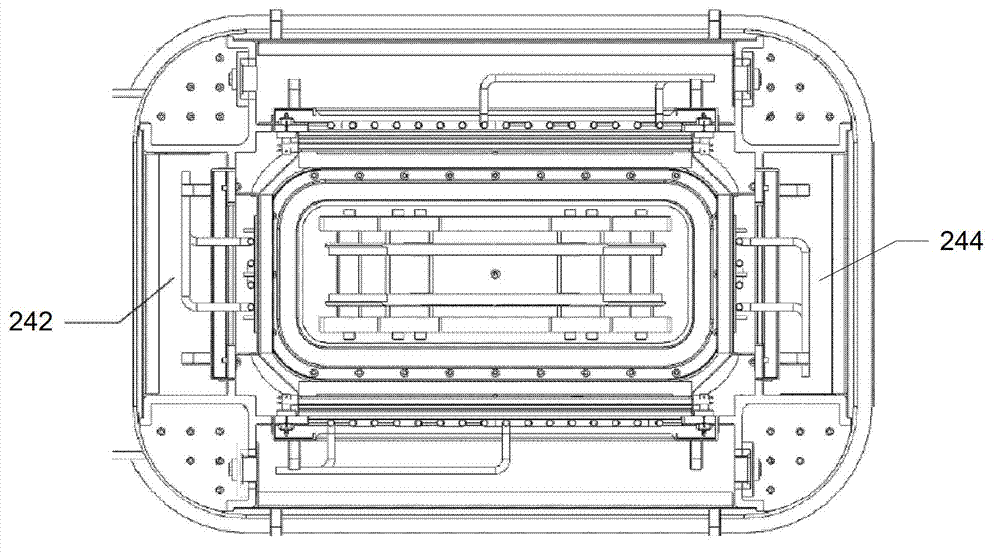

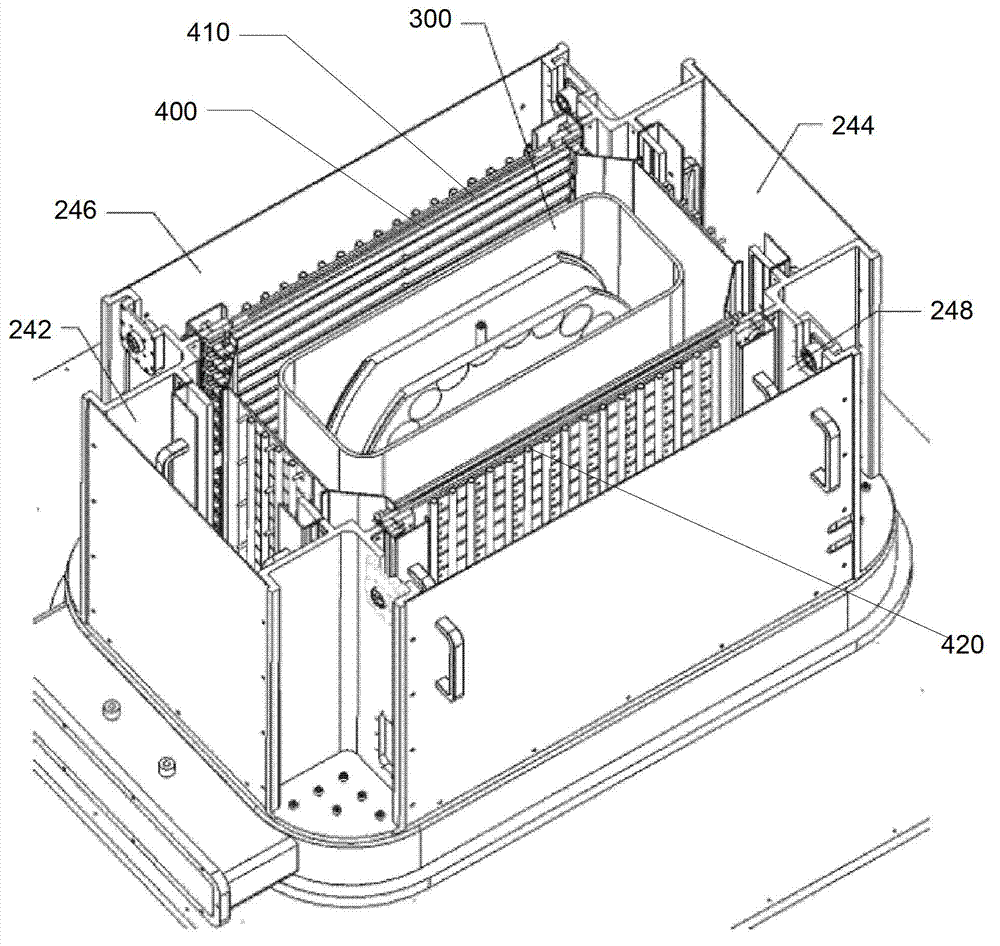

[0021] First, see figure 1 and image 3 According to the present invention, the chlorine gas etching and baking equipment 10 includes: a reaction chamber 300 for accommodating a graphite disc or an epitaxial substrate to be cleaned; a heating assembly 400, which is constructed outside the reaction chamber 300 and can be The operation increases the temperature within the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com