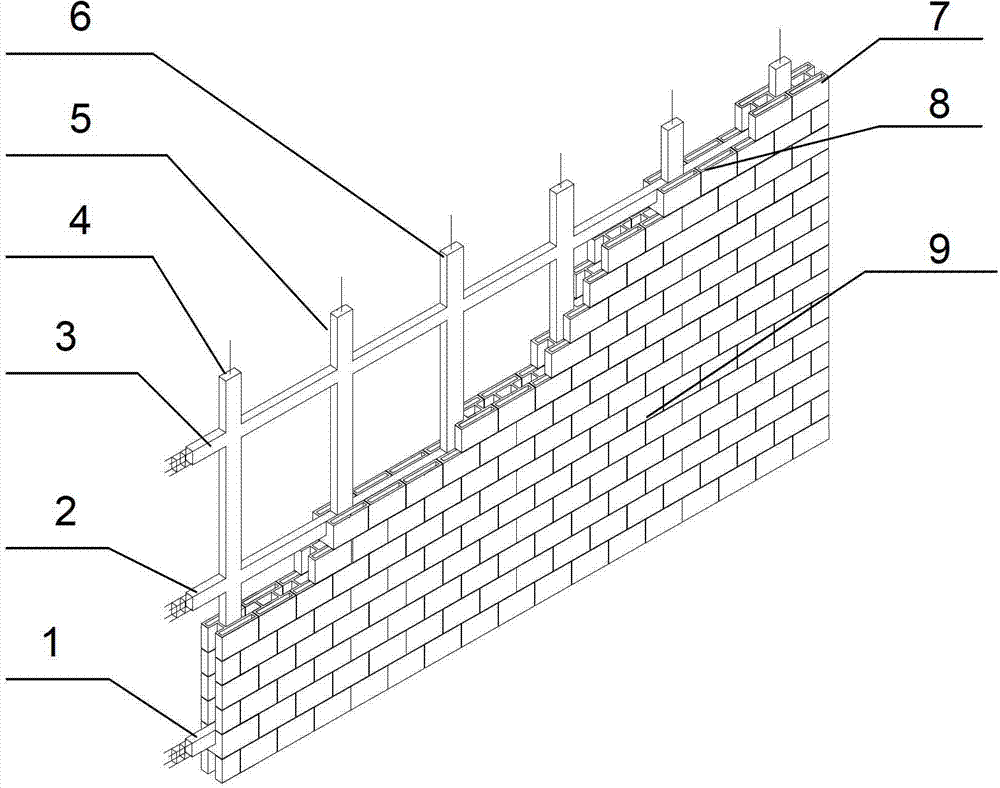

Hidden framework energy-saving building block wall body

A skeleton and block technology, applied in the field of new building walls, can solve the problems of simple structure, worrying safety situation, poor construction quality, etc., achieve strong deformation ability and lateral stiffness, significant social benefits, and improve seismic safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention first designs the horizontal strips (1, 2, 3) and stems (4, 5, 6), and determines the distance between the horizontal strips (1, 2, 3) and the stems (4, 5, 6). ) to consider the effect of reinforced concrete core columns (4, 5, 6) on improving the vertical bearing capacity of the wall and the effect of horizontal strips (1, 2, 3) on improving the seismic bearing capacity. Then according to the design, pre-buried vertical reinforcements at the bottom of the core column, and built concrete hollow blocks (7), and at the same time placed thermal insulation materials in the insulation interlayer (8), leveled with mortar, and then carried out the upper concrete hollow blocks (7). ) masonry, continue to place thermal insulation material in the thermal insulation interlayer (8) in the same way. According to the prior design, after the wall is built to a certain height, fluid concrete is poured at a certain interval, and the poured concrete is vibrated to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com