Structure and method for constructing multilayer heterogeneous gob-side entry retaining filling wall

A technology for filling walls and walls, which is applied in the direction of fillings, earthwork drilling, safety devices, etc., can solve the problems of difficult to ensure the longitudinal stability of the wall, easy to lose stability, and difficult to ensure dense contact, etc., to achieve a large shrinkable performance, good absorption of denaturation performance, and the effect of avoiding impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

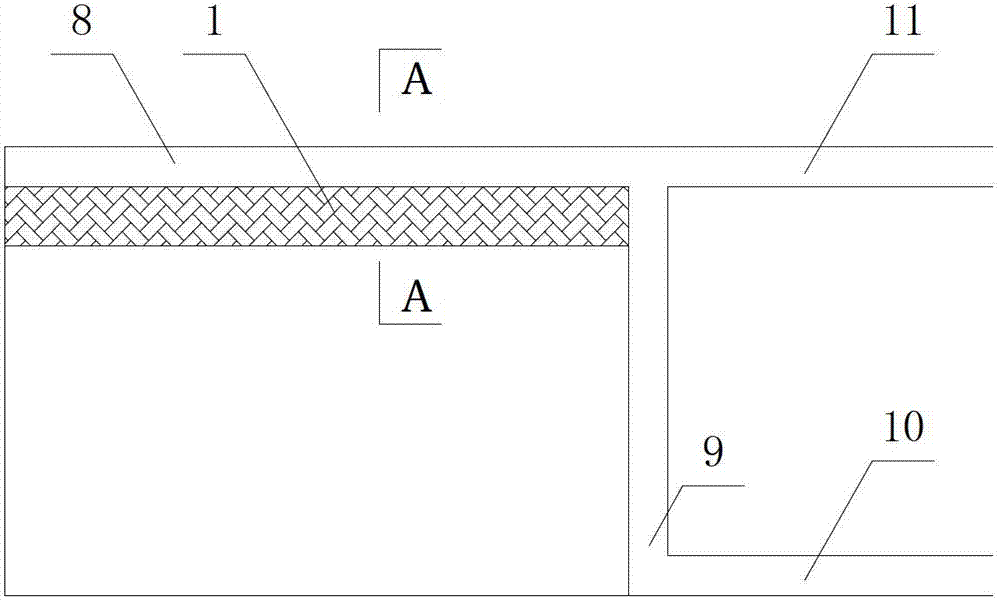

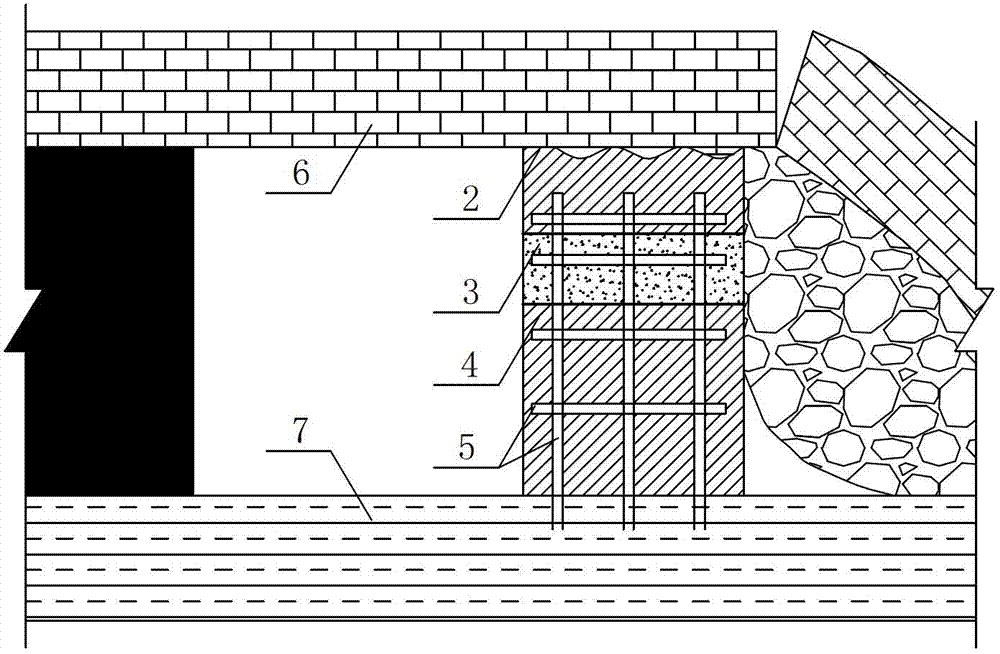

[0022] The structure of the multi-layer heterogeneous gob-side entry filling wall of the present invention is mainly composed of upper, middle and lower three-layer filling walls 1 of masonry gob-side entry retention 8, and the filling wall 1 includes an upper layer made of concrete Wall 2, containing 1~1.5kg / m 3 A middle wall 3 made of polypropylene fiber material concrete and a lower wall 4 made of concrete, three-dimensional reinforcing ribs 5 are provided in the upper, middle and lower walls. The height of the upper wall is 0.5~1m, the height of the middle wall is 0.25~0.5m, and the lower wall is the main bearing layer with a height of 1.5~2m.

[0023] In the method of constructing a multi-layer heterogeneous gob-side entry filling wall of the present invention, firstly, the vertical stress borne by the roof 6 of the roadway on the filling side is calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com