Fully Automatic High Purity Oxygen Under Cap Filling Machine

A high-purity, filling machine technology, used in mechanical equipment, equipment loaded into pressure vessels, gas/liquid distribution and storage, etc., can solve problems such as large pressure error, low purity, substandard, low efficiency, etc. Reduce less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

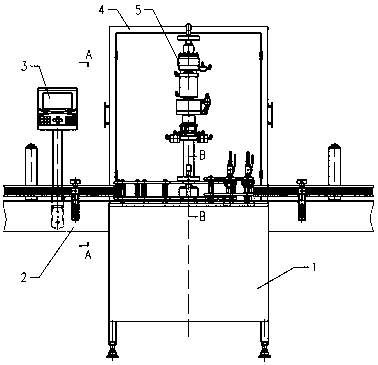

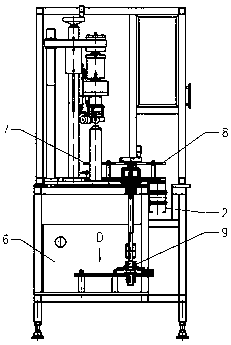

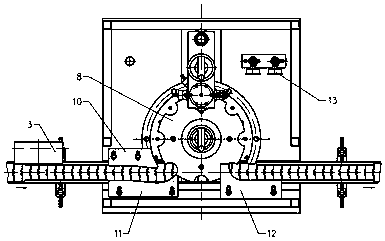

[0026] Fully automatic high-purity oxygen under-cap filling machine, which includes a frame 1, an upper cabinet 4 installed on the frame 1, a conveying line 2 passing through the frame 1, and a control box 3 installed on the side plate of the conveying line 2 , the indexing star wheel assembly 8 set on the frame platen, the first tank inlet guide assembly 10, the second tank inlet guide assembly 11, the tank outlet guide assembly 12, the main body of the filling machine under the cover 5, the gas distribution device 13 and the device Electrical box 6 and indexing mechanism 9 in frame 1.

[0027] The conveyor line 2 includes a conveyor line side plate 14, a conveyor line support bar 15, a barrier bracket 16, a conveyor belt 17, a conveyor line barrier 18 and a driving mechanism, and the conveyor belt 17 is a flat-top chain plate conveyor belt 17. The fence bracket 16 is fixed on the side plate 14 of the transmission line, and the fence 18 of the transmission line is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com