Analysis method for ingredients and mixing ratio of oil product and mixed oil by using terahertz spectroscopy

A technology of mixing ratio and analysis method, which is applied in the measurement of color/spectral characteristics and phase influence characteristics, etc., can solve the problems of waste of refined oil, economic loss, and reduction of refined oil quality, and achieve stable and accurate results and low misjudgment rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 101: Obtain the terahertz frequency range, and solve the n of multiple measurements si (1THz) signal s varying with measurement time n (t);

[0040] 102: According to the signal s n (t) Determine the time period t during which the mixed oil appears in the measurement time 1 ~t 2 ; Respectively seek in 0~t 1 time and t 2 ~t end The types of refined oil in the pipeline sequentially transported within a certain period of time;

[0041] 103: In the terahertz frequency range, for t 1 ~t 2 The absorption coefficient α corresponding to the measurement sequence occurring in time si (w) Carry out the least squares fitting to solve the respective volume percentages of the two refined oils in the corresponding mixed oil.

[0042] Further, step 101 is specifically:

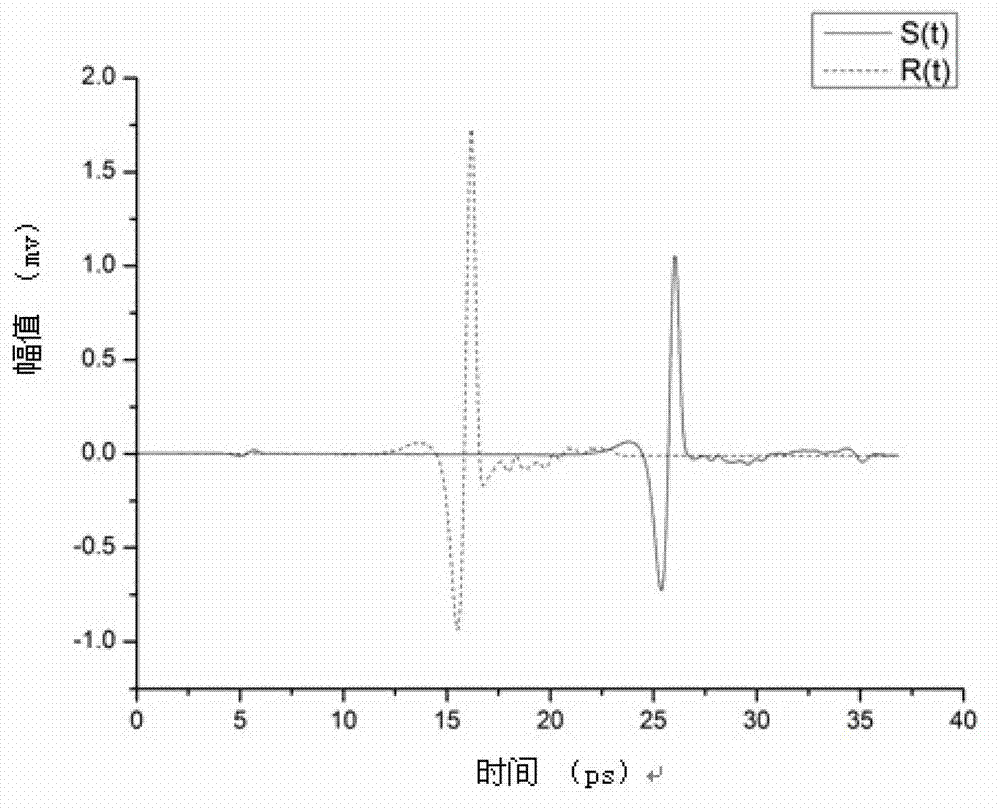

[0043] 1) Obtain the terahertz time-domain waveform S(t) passing through the full sample cuvette and the reference terahertz time-domain waveform R(t) passing through the empty cuvette with the same thicknes...

Embodiment 2

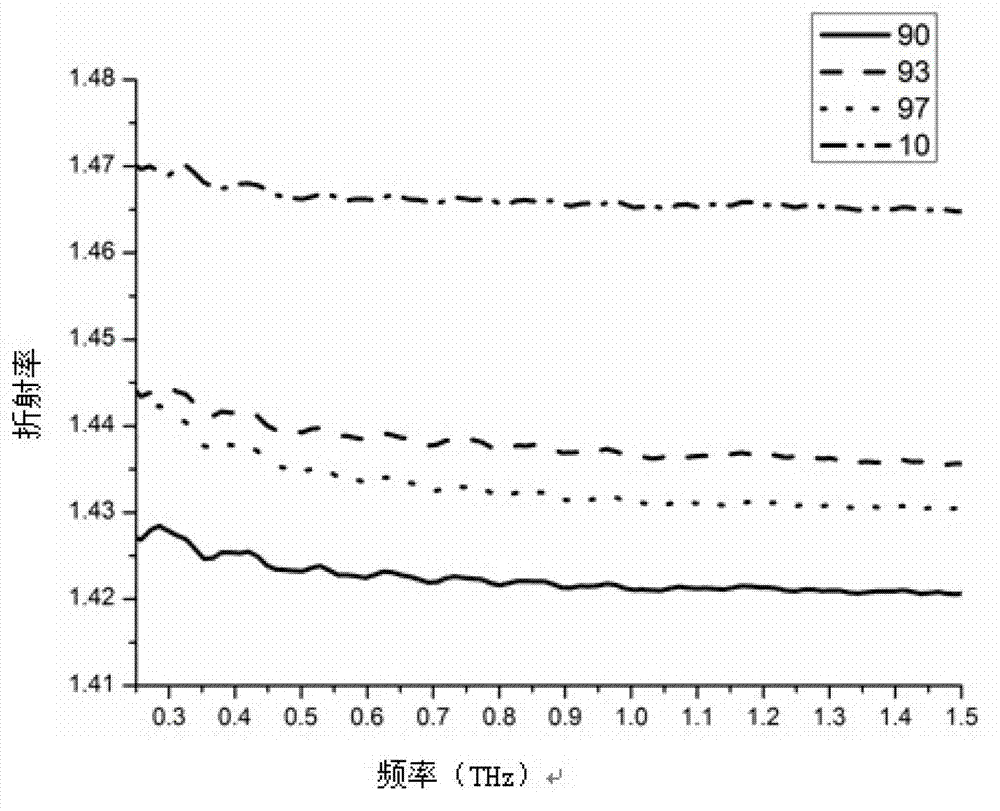

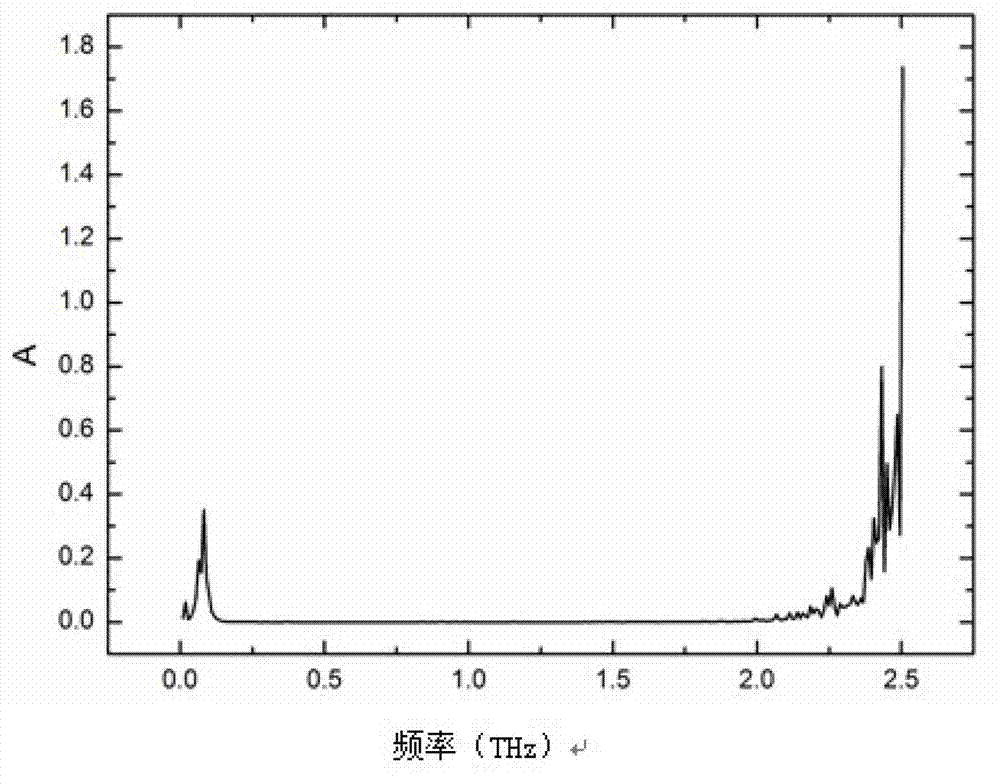

[0060] The following four kinds of refined oils (90#, 93#, 97# and -10 diesel oil) delivered in sequence are used as experimental samples of mixed oil, and the analysis method of terahertz spectroscopy on the composition and mixing ratio of finished oil and mixed oil is described in detail. see figure 2 , see the description below:

[0061] 201: Take the appropriate amount of four oil products sequentially transported in the pipeline as experimental samples, respectively obtain the terahertz time-domain waveform S(t) through the cuvette filled with the sample, and the space ratio through the same thickness according to the terahertz time-domain spectrometer. The reference terahertz time-domain waveform R(t) of the color dish;

[0062] see image 3 and Figure 4 , the terahertz time-domain waveform S(t) and the same thickness The reference terahertz time-domain waveform R(t) of an empty cuvette. The quantity and type of refined oil are set according to the needs in practi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com