Photo-etching parameter correction method and system thereof

A lithography parameter and lithography machine technology, which is applied in the field of lithography parameter correction method and system, can solve the problems of delayed product delivery, reduced lithography machine utilization rate, improved photoresist rework rate, etc., saving manpower and material waste, reducing photoresist rework problems, and reducing photoresist rework rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

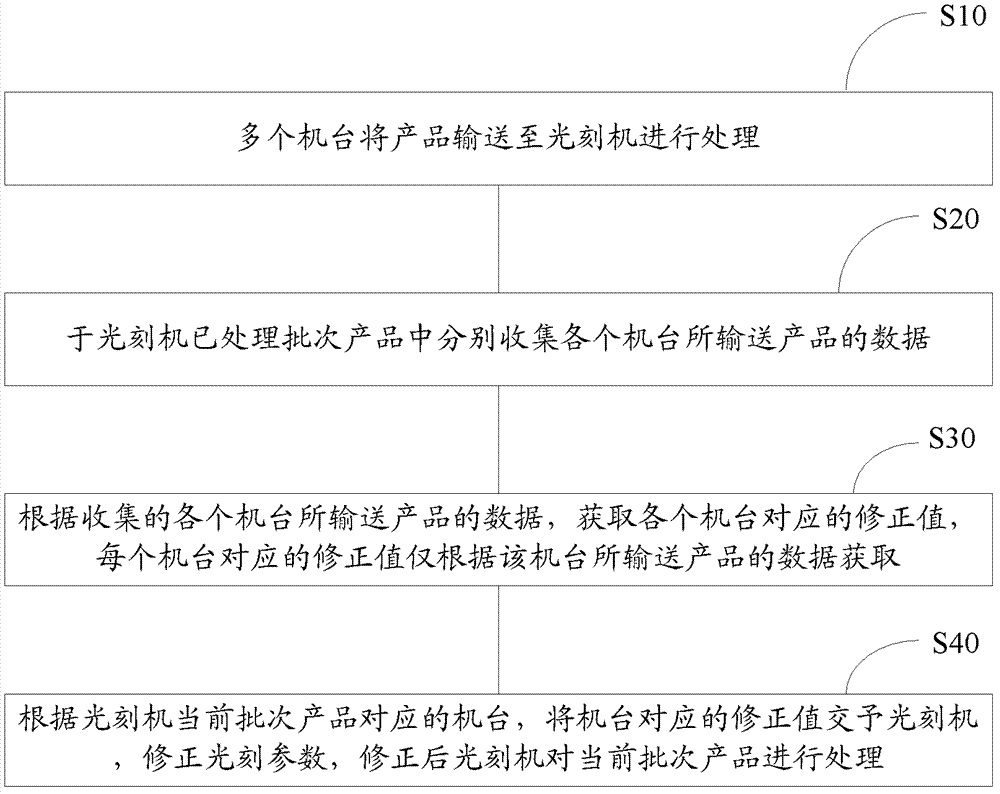

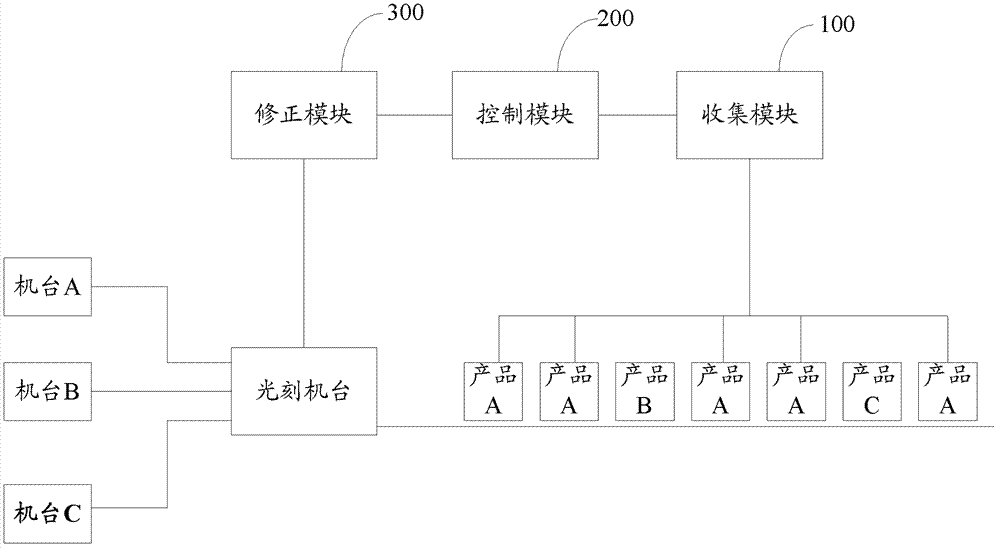

[0028] figure 1 It is a flow chart of a method for modifying lithography parameters in an embodiment, the method comprising:

[0029] S10: Multiple machines transport the products to the photolithography machine for processing.

[0030] The products required by the lithography machine are transported by multiple machines for other processes, and each machine transports the product to the lithography machine for lithography processing after completing its own process.

[0031] S20: Collect the data of the products conveyed by each machine from the batches of products processed by the photolithography machine.

[0032] Due to the differences in each machine, in order to ensure the accuracy of the correction value, it is necessary to collect the parameters of the products conveyed by each machine for each of the multiple machines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com