Method and device for photoresist coating

A photoresist and coating technology, which is applied in the direction of photo-engraving process coating equipment, electrical components, semiconductor/solid-state device manufacturing, etc. The effect of improving the uniformity of resistance thickness, reducing the defect rate, and solving the problem of over-etching of the protective layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

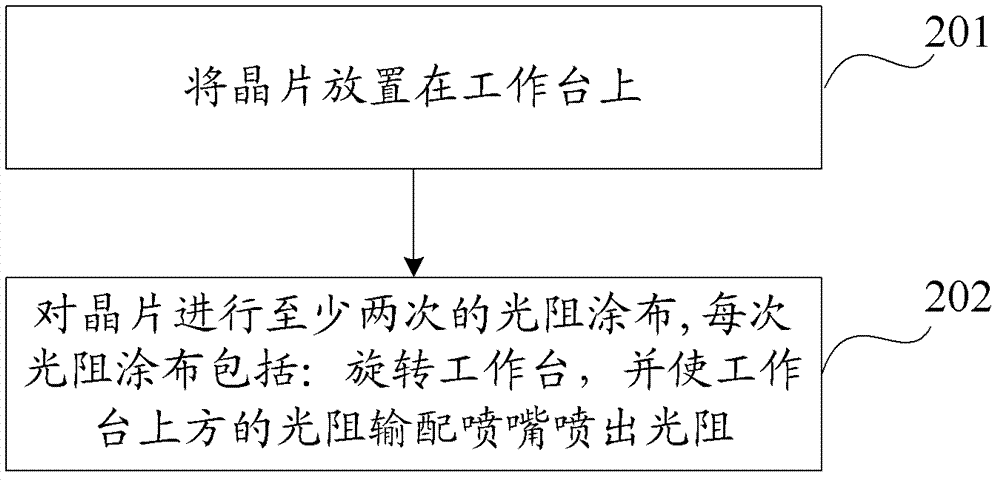

[0018] In the embodiment of the present invention, when photoresist coating is performed on the uneven surface of the wafer, photoresist coating is performed twice, three times, or multiple times, so that the thickness of the photoresist coated in the groove area will be thicker to avoid concave and convex. The thickness of the photoresist coated on the sidewall area of the groove is not enough to resist etching and cannot protect the circuit.

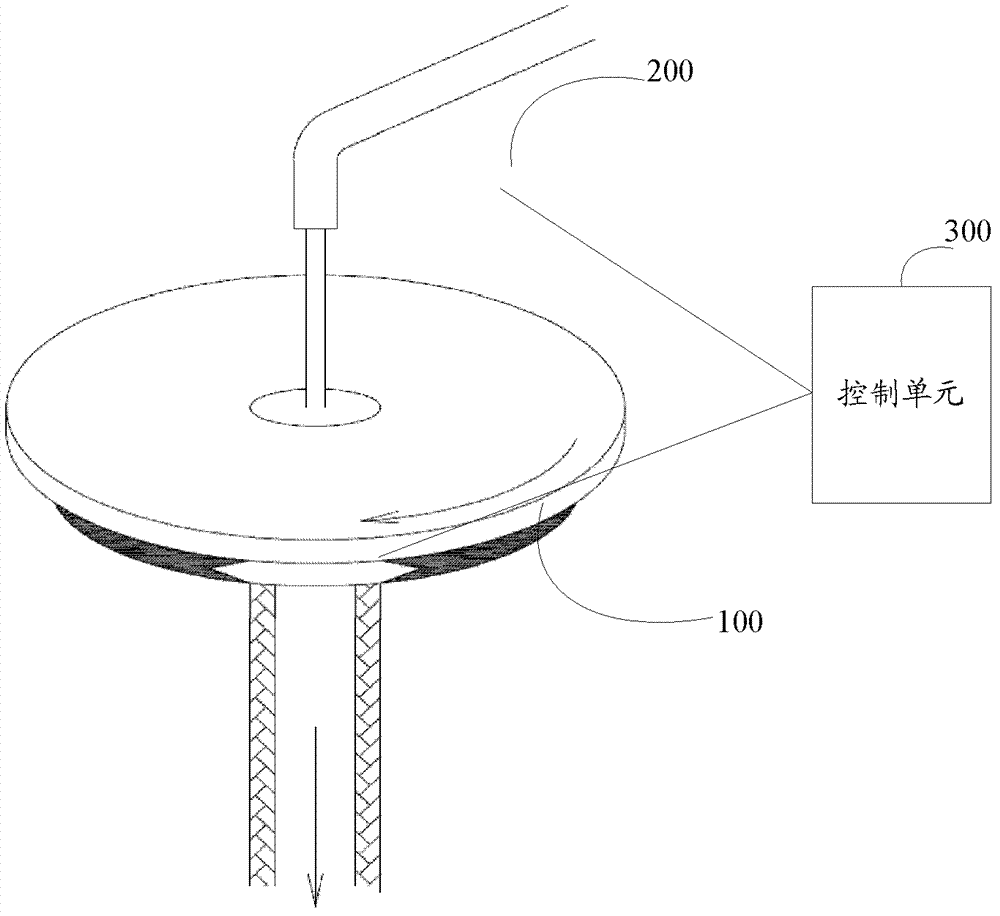

[0019] The process of photoresist coating generally adopts the center selective spraying method, and the photoresist coating device is such as figure 1 As shown, it includes: a workbench 100 , a photoresist distribution nozzle 200 and a control unit 300 . in,

[0020] The worktable 100 is used for placing wafers and can be rotated under the control of the control unit 300 . Generally, the control unit 300 controls the rotational speed of the worktable 100 .

[0021] The photoresist distribution nozzle 200 is located above the workb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com