A Tool Path Generation Method Based on Triangular Mesh Offset Compensation and Its NC Machining System

A triangular mesh and path generation technology, applied in general control systems, control/adjustment systems, program control, etc., can solve the problems affecting the machining accuracy of NC machining, machining overcut, unavoidable offset and overcut, etc. problems, to achieve the effect of reliable use, over-cutting, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

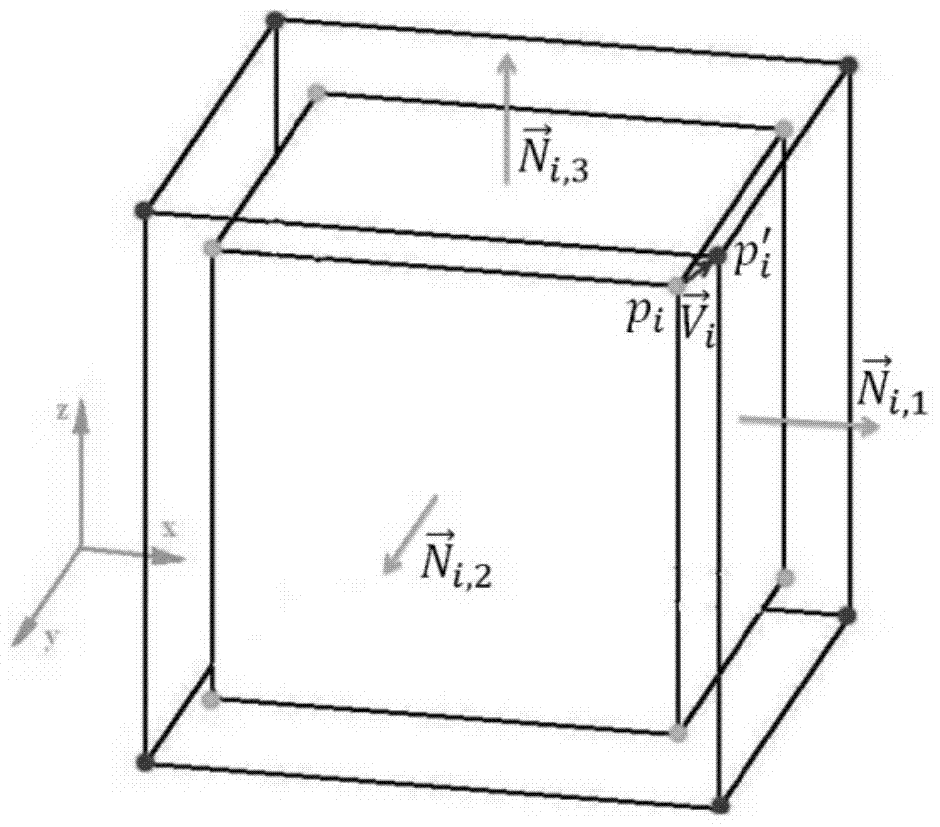

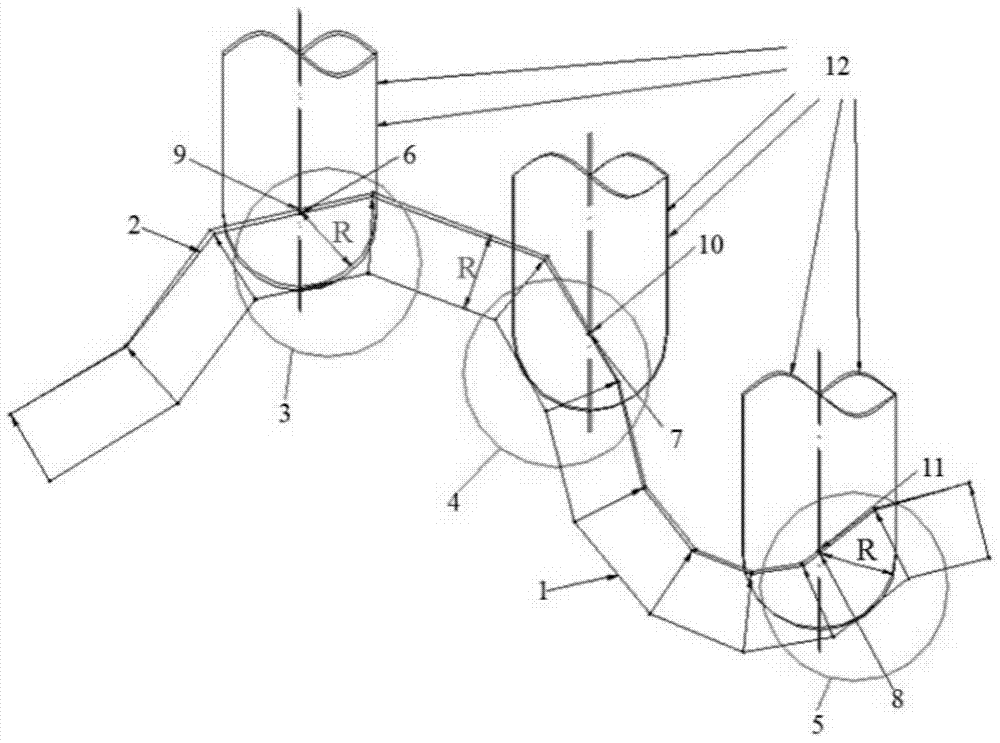

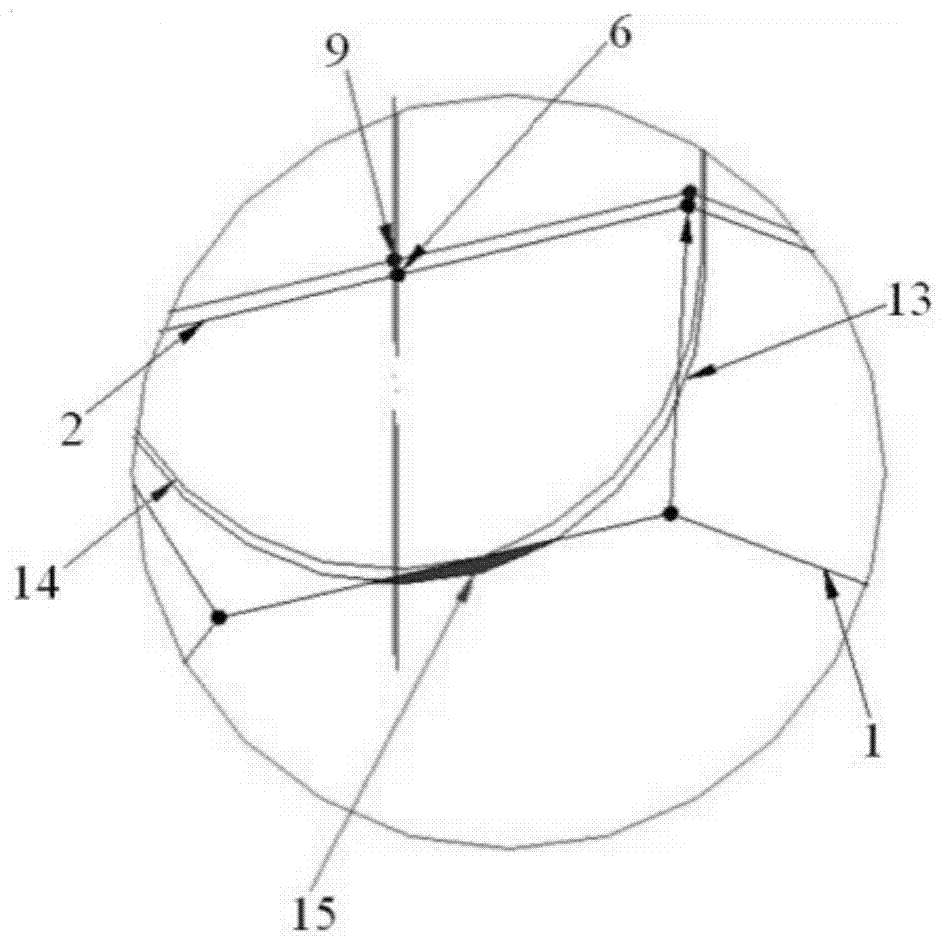

[0065] The complete process of the present invention is as Image 6 As shown, the complete triangular mesh establishment process is as follows: (1) establish the triangular mesh model (2) bias the triangular mesh model according to the vertex bias method and obtain the biased triangular mesh model, in which Set the distance as the radius of the ball head tool; (3) Obtain the data information of the triangular mesh, reconstruct the data information of the triangular mesh model, and extract the coordinate information of each vertex and the data information of the adjacent surface; (4) Calculate the normal vector direction of each vertex of the triangular mesh through the data information of the adjacent surface of the vertex; (5) calculate the offset compensation distance according to the offset compensation method; (6) perform binary calculation on each vertex according to the calculated compensation distance Secondary offset; (7) Connect all vertices obtained after the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com