Monocrystalline silicon alkali polishing additive and use method thereof

A single crystal silicon alkali and additive technology, which is applied in the field of solar cells, can solve problems such as unevenness, thin oxide layer, and battery failure, and achieve the effects of reducing environmental pollution, improving polishing effect, and protecting against damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

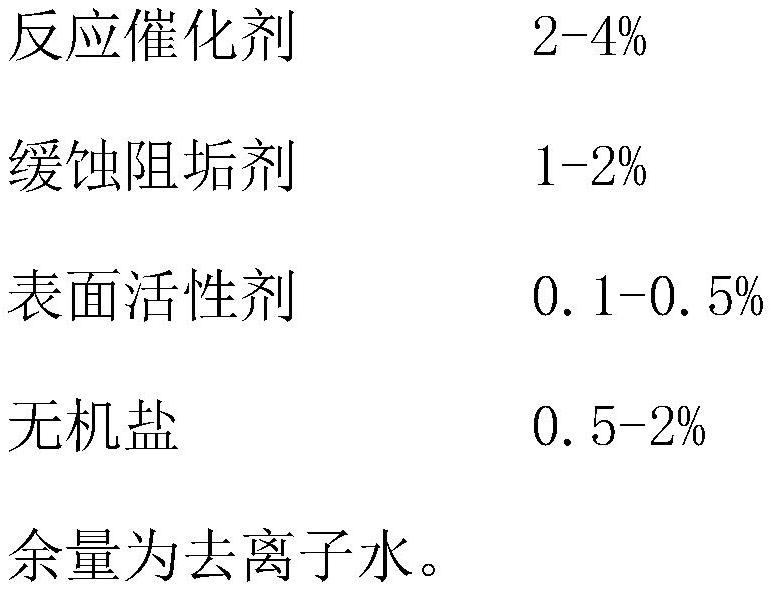

[0027] Dissolve 50 g of ammonium persulfate, 50 g of polyepoxysuccinic acid, 25 g of glucose, 5 g of sodium dodecylbenzenesulfonate, 15 g of sodium benzoate, and 50 g of sodium lactate into 5 L of deionized water, and stir evenly to obtain an alkali polishing additive.

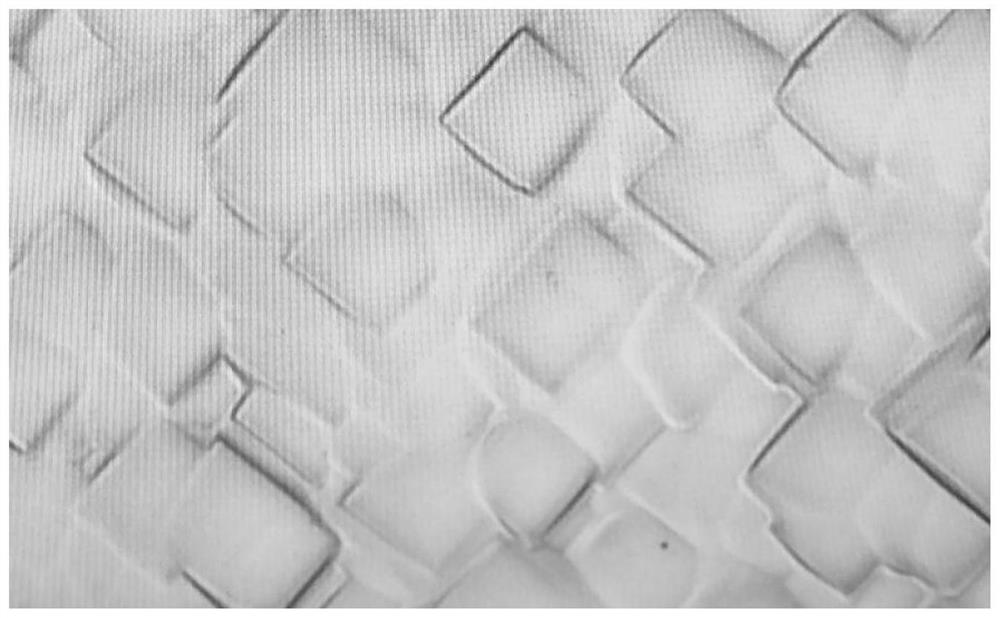

[0028] Add 12L of sodium hydroxide (45% solid content) and 3L of alkali polishing additive into 330L of deionized water to obtain an alkali polishing solution, and raise the temperature to 65°C. Then put the PSG-removed silicon wafer into it for polishing after pre-cleaning, and then successively wash with deionized water, post-clean, wash with deionized water, pickle, wash with deionized water, and then dry after slow pulling. The weight loss of the prepared silicon wafer was measured, the size of the lattice base was detected by a scanning electron microscope, and the reflectance was measured by a D8 reflectance meter.

Embodiment 2

[0030] Dissolve 50 g of sodium percarbonate, 50 g of polyaspartic acid, 25 g of glucose, 5 g of alkyl glycosides, 15 g of sodium benzoate, and 50 g of sodium lactate into 5 L of deionized water, and stir evenly to obtain an alkali polishing additive.

[0031] Add 12L of sodium hydroxide (45% solid content) and 3L of alkali polishing additive into 330L of deionized water to obtain an alkali polishing solution, and raise the temperature to 65°C. Then put the PSG-removed silicon wafer into it for polishing after pre-cleaning, and then successively wash with deionized water, post-clean, wash with deionized water, pickle, wash with deionized water, and then dry after slow pulling. The weight loss of the prepared silicon wafer was measured, the size of the lattice base was detected by a scanning electron microscope, and the reflectance was measured by a D8 reflectance meter.

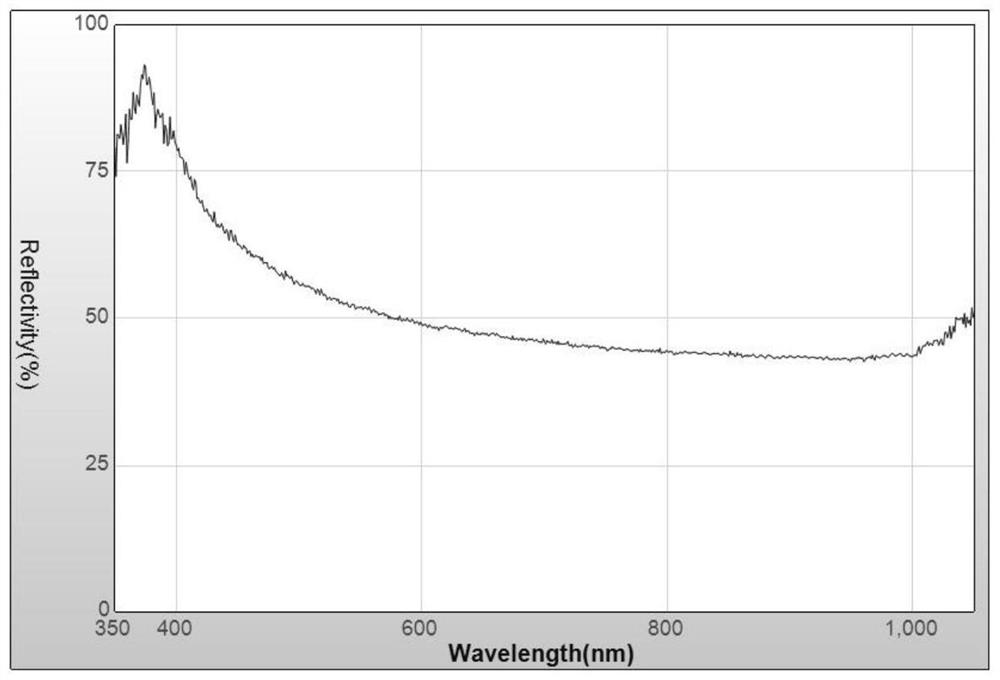

[0032] figure 1 It is the reflectance diagram of the polished surface of the silicon wafer prepared in Exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com