Skin care emulsion composition

A composition and emulsion technology, applied in skin care preparations, hair care, pharmaceutical formulations, etc., can solve problems such as aesthetics, cost, and flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example I

[0082] Example I: Example of Invention

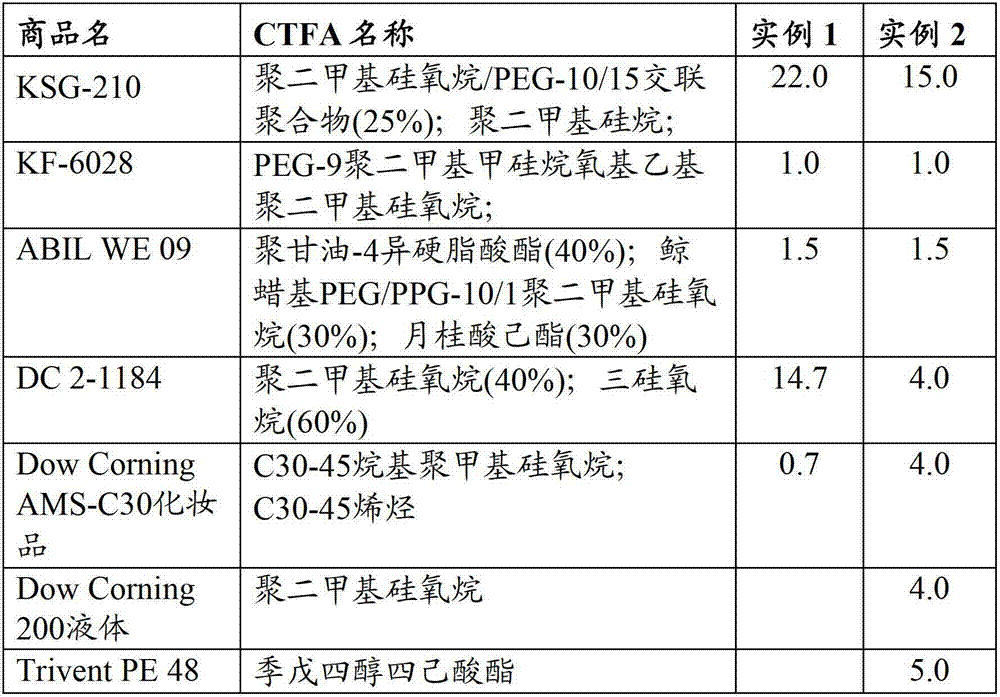

[0083] The compositions shown below in Table 1, Inventive Examples 1-2, were prepared according to the invention. They contain zinc-copper powder, water sensitive granules.

[0084] Table 1

[0085]

[0086]

[0087]Inventive Example 1 was prepared by forming an aqueous phase by mixing water, EDTA, sodium chloride, butanediol, silica into a vessel and heating to 80°C. The oil phase was prepared by mixing KSG-210, KF-6028, Abil WE09, DC2-1184, AMS-CS30, TMF1.5, and Propylparaben into a vessel and heating to 80°C with paddle mixing. When both phases reached 85°C, the water phase was slowly added to the oil phase. After emulsification, turn off the heat and allow the emulsion to mix for 10 minutes. The emulsion was then homogenized for 5 minutes using a Silverson homogenizer. The emulsion was then re-stirred with a paddle mixer and allowed to cool to 25°C. Add the zinc / copper powder with stirring and mix until homogeneous.

...

example II

[0089] Example II: Comparative Example

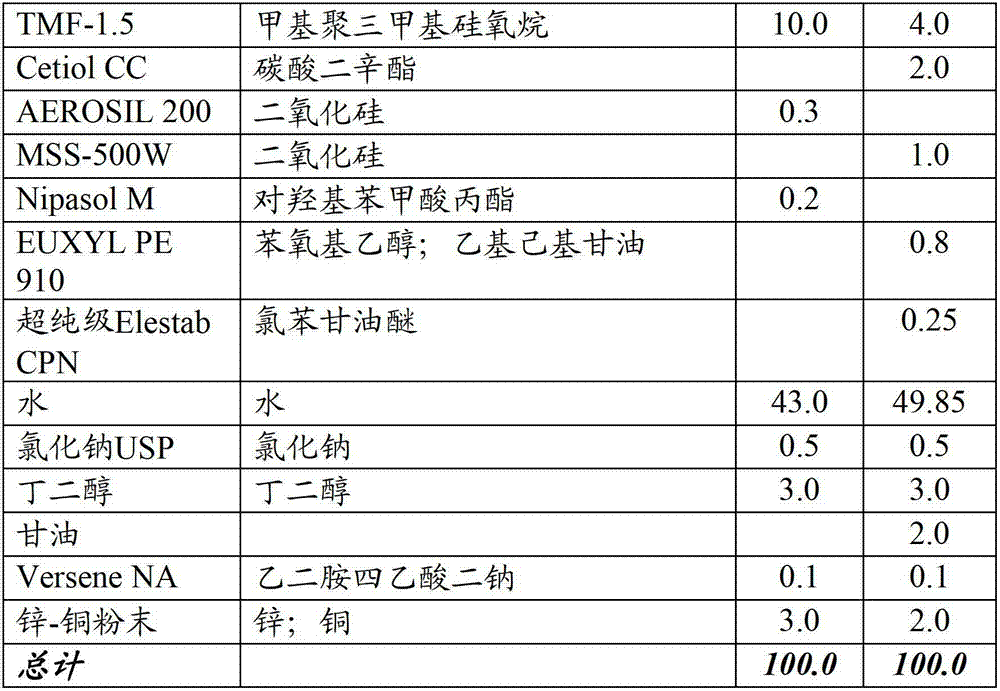

[0090] The composition shown below in Table 2, Comparative Example 1, was prepared. It also contains zinc-copper powder.

[0091] Table 2: Comparative Example 1

[0092]

[0093] Comparative Example 1 was prepared by roll milling Phase A (titanium dioxide to and including dimethicone). Add Phase A to Phase B (Dimethicone / Vinyl Dimethicone Crosspolymer to Zinc / Copper Powder) and heat to 60°C. Phase C (water to EDTA) was mixed and heated to 60°C. Add phase C to the phase A / B mixture and allow to mix for an additional 15 minutes after adding phase C. The mixture was then homogenized for 3 minutes at 30°C.

example III

[0094] Example III: Invention Example

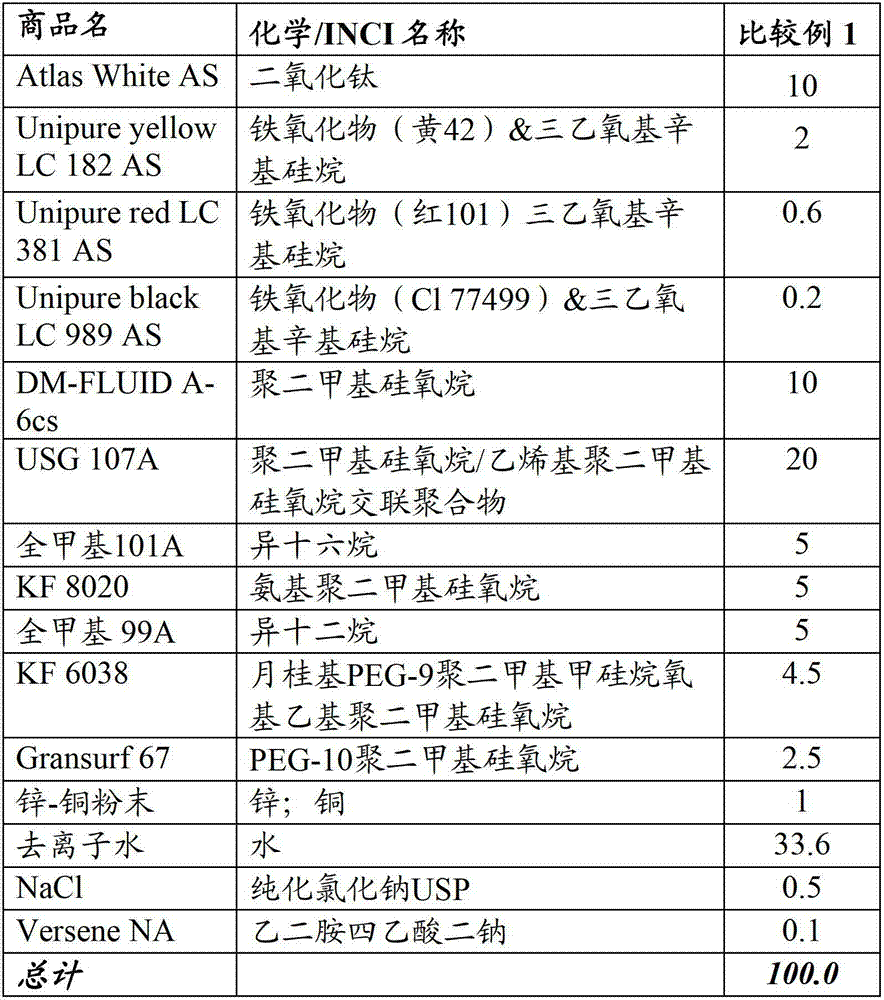

[0095] Inventive Examples 3-4, shown in Tables 3-4, were prepared according to the inventive examples described herein. They also contain zinc-copper powder.

[0096] Table 3: Invention Example 3

[0097]

[0098]

[0099] Inventive Example 3 was prepared by mixing together the oil phase (secondary dimethicone up to and including paraben) in a main kettle and heating to 80C. Prepare the aqueous phase by mixing water to EDTA and heating to 80C. The water phase was added to the oil phase over a period of 20 minutes maintaining the temperature above 70C. The mixture was then mixed for an additional 15 minutes at 75C. Remove the heat source and add the second oil phase (titanium dioxide to and including the first dimethicone) with dispersed pigments at a temperature of 60-70C. Allow to mix for 20 minutes, then homogenize for 3 minutes at 60C. The batch was cooled to 25C and the zinc / copper powder was added, mixing slowly using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com