Single-side pedicle screw-driving auxiliary device and manufacturing method thereof

A pedicle screw and auxiliary device technology, applied in the field of medical equipment, can solve the problems of easy error in the registration of the vertebral body surface, long learning period, and high requirements for equipment, so as to reduce the risk of exposure infection, convenient disinfection, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

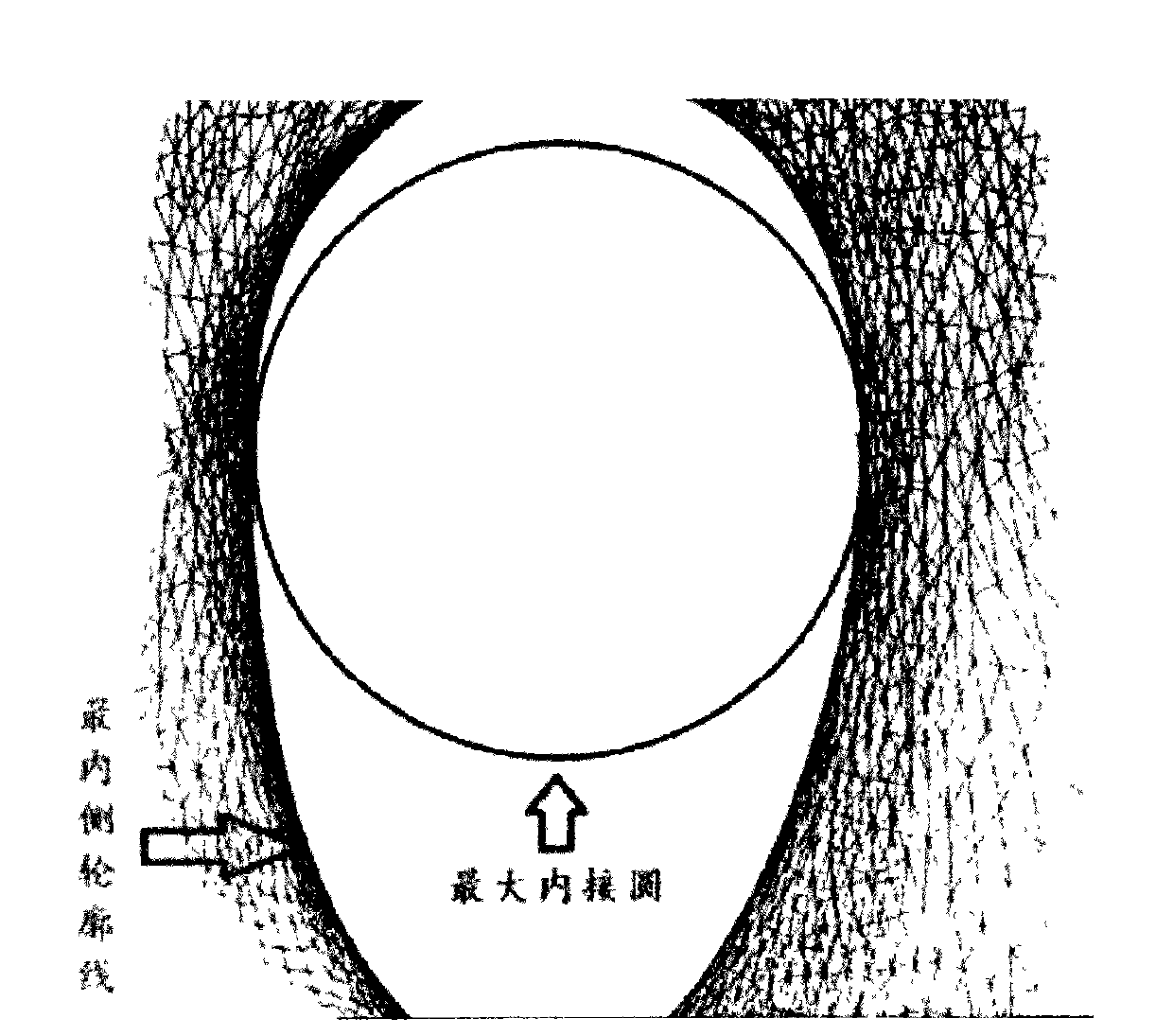

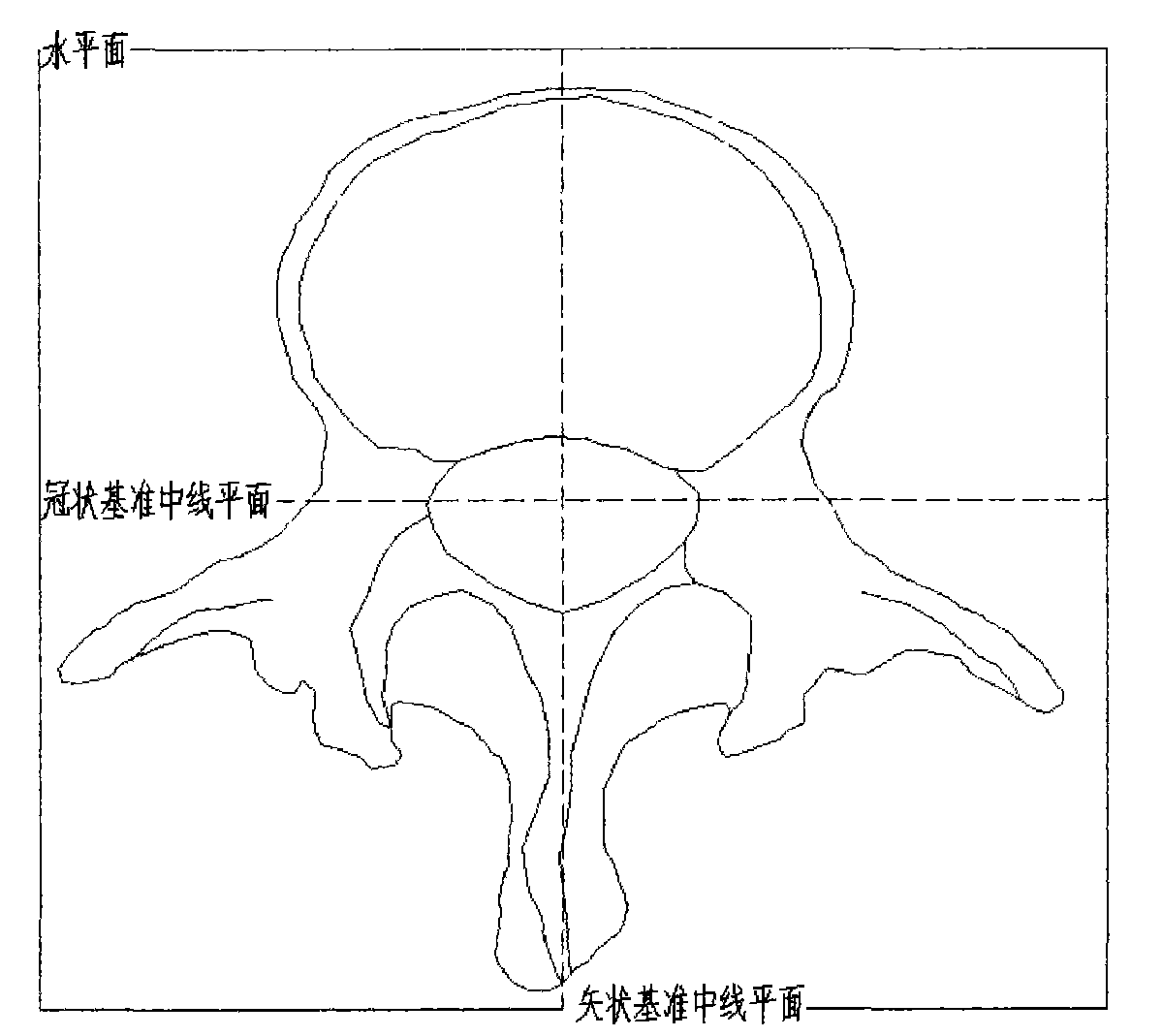

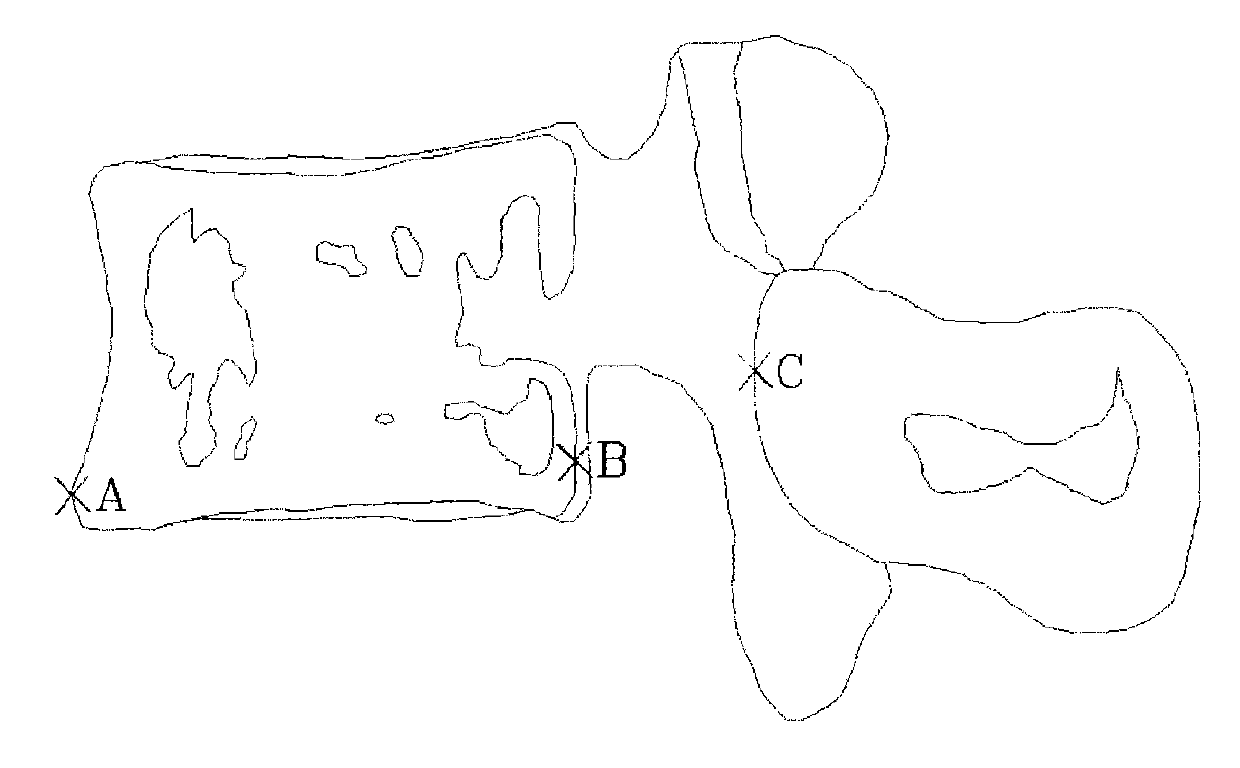

[0041] Embodiment 1 The structure of the auxiliary device for unilateral pedicle screw insertion

[0042] Such as Figure 6 and Figure 7 As shown, the unilateral pedicle screw screw driving auxiliary device of the present invention includes: a guide hole 1, a sleeve 2, a first clip 3, a second clip 4, a torsion spring 5, and a transverse shaft 6, wherein the guide The hole 1 is connected to the bottom 31 of the first clip, the middle part of the first clip and the second clip has connecting pieces 32 and 42, the connecting pieces have holes, and the transverse axis 6 passes through the hole of the connecting piece of the first clip and the torsion spring in sequence 5 and the hole of the second clip. The angle α between the first clip and the second clip is preferably 25°-65°.

[0043] The bushing 2 includes a bushing head 21 and a bushing body 22 , the bushing head is directly connected to the bushing body, wherein the hole on the bushing head 21 communicates with the inn...

Embodiment 2

[0044] Example 2 Preparation of unilateral pedicle screw screw insertion aid

[0045] 1. Materials and methods

[0046] 1. Materials

[0047] One normal adult isolated lumbar vertebral dry bone specimen treated with 10% formalin was taken, and its attached soft tissue structures were dissected and removed. The specimens were provided by the Department of Anatomy, Peking Union Medical College.

[0048] SIEMENS / Sensation 64-slice CT machine, scanning parameters: slice thickness 2mm, slice distance 2mm, tube voltage 120kV, current 225mAs, resolution 512*512pxl

[0049] Objet EDEN250 3D reconstruction printer, technical parameters: molding resolution X-axis: 600dpi: 42u, Y-axis: 300dpi: 84u, Z-axis: 1600dpi: 16u, accuracy 0.1-0.2mm (accuracy depends on object shape, part use and printing size ), power supply 110-240VAC50 / 60Hz1.5KW, operating environment 18-25℃, relative humidity 30%-70%

[0050] FullCure720: Objet's medical transparent molding material.

[0051] 2. Method

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com