Continuous type cross-shaped feeding processing device

A processing device and feeding technology, applied in the field of parts processing machinery, can solve the problems of difficult one-time processing and low efficiency, and achieve the effects of low production cost, high degree of automation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]

[0026] Embodiments of the present invention are described below in conjunction with the accompanying drawings, but are not limited to the following embodiments:

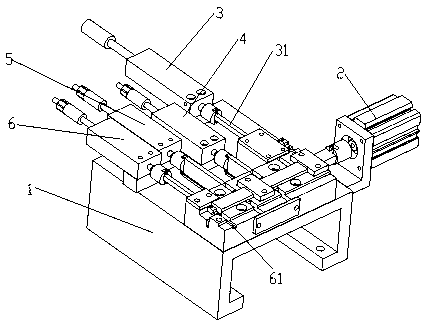

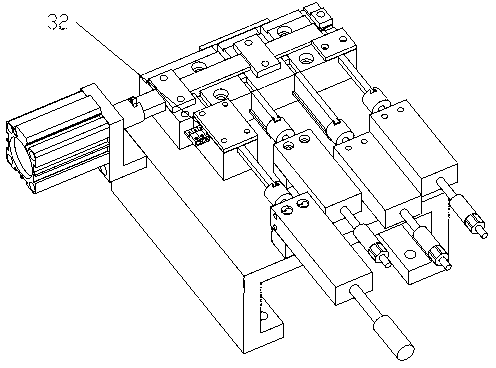

[0027] see figure 2 , image 3 , Figure 4 , providing a continuous cross feeding processing device, comprising a workbench 1 and a positioning block 7 arranged on the workbench 1, a feed cylinder 3 and a feed cylinder 2 are arranged on the workbench 1 to cooperate, the The feed cylinder 3 will image 3 After the blank body of the terminal post shown in the figure enters through its input port 32, it is transported to the front end of the ejector rod 21 of the feeding cylinder 2 located on the positioning block 7, and the positioning block 7 is provided with a The common channel 71 that the ejector rod 21 of the cylinder 2 is matched with is provided with three slot-shaped openings 41, 51, 61 in the shape of a "ten" at equidistant distances on the shared channel 71, and the first two slots in the shape ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap