Polyamide 56 high-tenacity yarn for demolding cloth, demolding cloth and preparation method and application thereof

A polyamide and high-strength technology, which is applied in the field of polyamide materials, can solve the problems that the release performance of the release cloth needs to be improved, and achieve the effects of saving production investment, excellent stretching, and easy tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

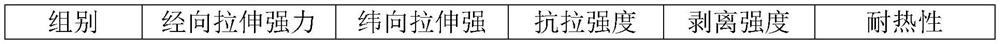

Examples

Embodiment 1

[0135] 1. The preparation of polyamide 56 high -strength silk includes the following steps:

[0136] (1) Poinide 56 resin to increase the phase and adhes up, adjust the water, obtain high -adhesive polyamide resin, heated to the melting state, and obtain a high -adhesive polyamide melt;

[0137] (2) Transfer high -adhesive polyamide melts to draw into the spinning box through the melt pipeline to form a newborn wire;

[0138] (3) Pre -heating, cooling, oil, pre -network, multi -level stretching, tension thermal fixed type, two -level relaxation thermal setting, main network, and wound, obtaining polyamide 56 high -strength wires.

[0139] Among them, the consolidation temperature of the solid phase (1) is 150 ° C; the solid -phase adhesion time is 30h; the polyamide resin water is divided into 600 ppm; the relative viscosity of the polyamide resin after water is 3.1, the polyamide resin Copper ion content is 65ppm;

[0140] The heating in the step (1) is performed in the screw ext...

Embodiment 2

[0156] 1. Polyamine 56 high -strength silk, preparation method is the same as the implementation example 1, the difference is:

[0157] Step (1) The consolidation temperature of the solid phase is 160 ° C; the solid phase increased time is 20h; the polyamide resin water after the water is divided into 500 ppm; The content is 68ppm;

[0158] Step (2), the temperature of the spinning box is 288 ° C;

[0159] Polyamine 56 high -strength silk has the following characteristics: the content of copper ions is 65ppm; the fibrousness is 233DTex; the number of holes is 36 holes; the fracture strength is 1900cn; the broken strength is 8.1cn / dtex; The elongation rate of the break is 22.5 %; 4.7CN / DTEX fixed load elongation rate is 9.5 %; 177 ° C, 2min dry thermal contraction rate is 6.5 %; 9.0 %.

[0160] 2. The preparation method of polyamide 56 removal is the same as the embodiment 1. The difference is that the thermal fixed temperature is 130 ° C.

[0161] The preparation of the prepared p...

Embodiment 3

[0163] 1. Polyamine 56 high -strength silk, preparation method is the same as the implementation example 1, the difference is:

[0164] Step (1) The consolidation temperature of the solid phase is 165 ° C; the solid -phase adhesion time is 25h; the polyamide resin water after the water is divided into 560 ppm; the relative viscosity of the polyamide resin after water is 3.4; The content is 75ppm;

[0165] The heating in the step (1) is performed in the screw extrusion machine, and the screw extrusion machine is divided into five zones heating. Among them, the temperature in the first area is 278 ° C, the temperature of the second zone is 288 ° C, the temperature of the three districts is 293 ° C, the four districts are in the four districts, and the four districts are in the four districts. The temperature is 298 ° C, the temperature of the five districts is 295 ° C;

[0166] In step (2), the temperature of the spinning box is 292 ° C.

[0167] Polyamine 56 high -strength silk has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com