PET cleaning ball processing equipment

A processing equipment and cleaning ball technology, which is applied in recycling technology, textile and papermaking, and textile material cutting, etc., can solve the problems of automatic production of difficult products, difficulty in improving processing efficiency, and overall inconvenientness, so as to achieve automatic production and processing , Realize the effect of automatic production and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

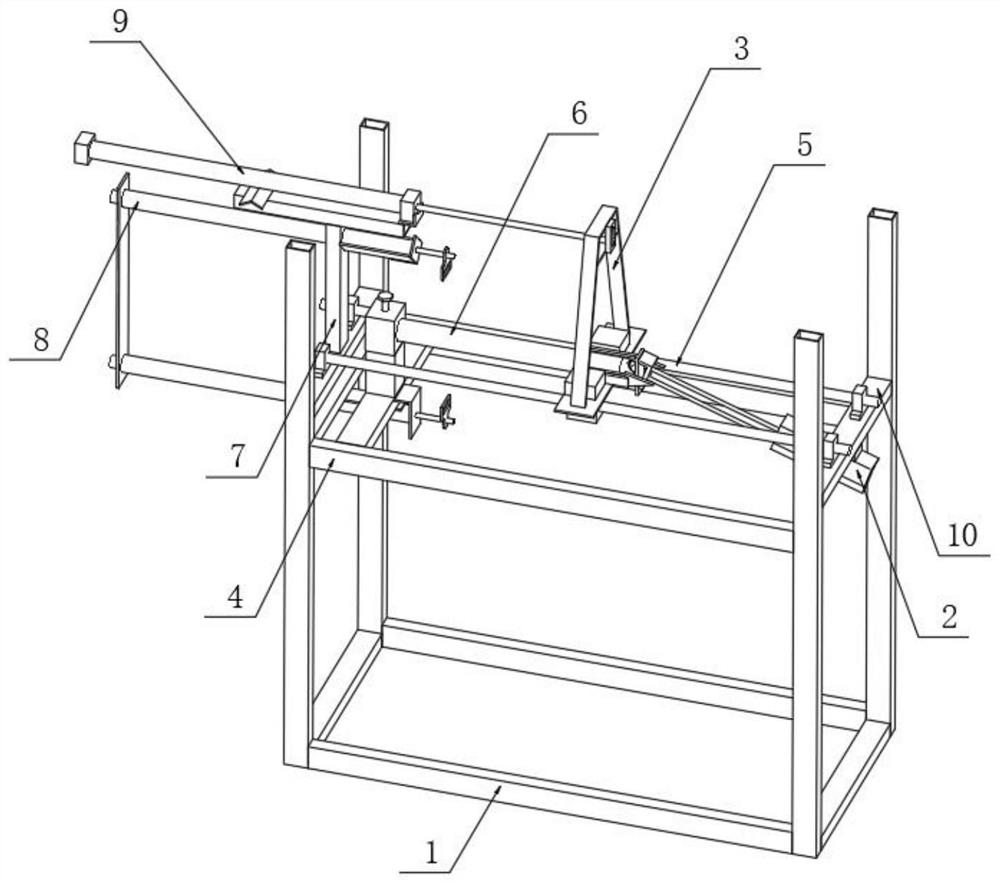

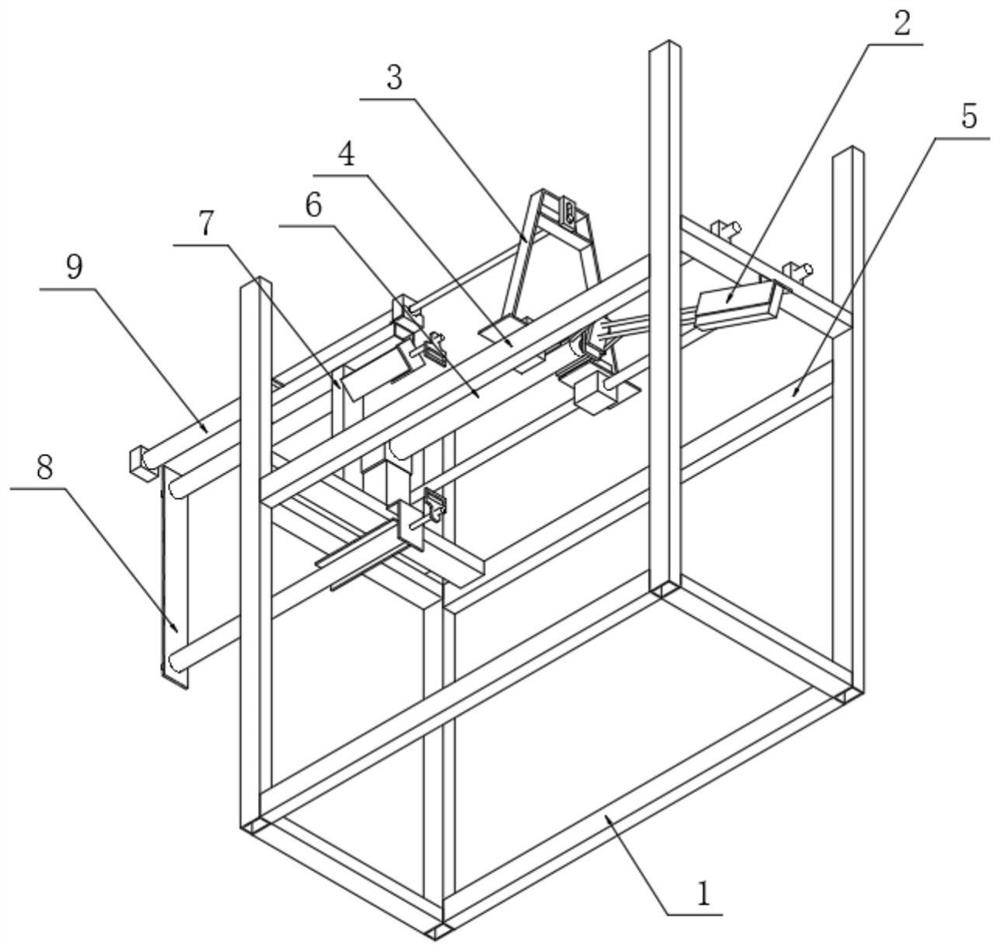

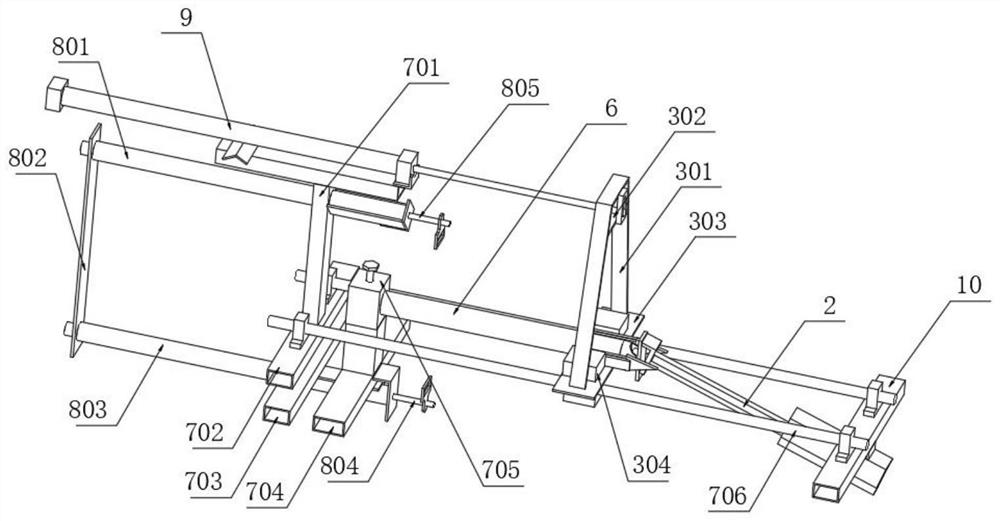

[0027] see Figure 1-8, In the embodiment of the present invention, a PET cleaning ball processing equipment includes a fixed bracket 1, a fixed rod 201, a movable support plate 301, a vertical support frame 701 and a vertical installation plate 802. The top surface of the fixed bracket 1 is fixedly connected with The side connecting plate A4 and the side connecting plate B5 are fixedly connected to the inner part of the fixed bracket 1 with the support connecting frame 7, the reclaimer 8 and the connecting plate 10. When processing the PET cleaning ball, the overall processing can be more convenient. The entire PET material flat wire is knitted into a tube, and the entire tie can be processed in one piece during the entire use. The PET material flat wire is used to warp into a tube, and the two transmission shafts are heated by an electric furnace at 300 °C to shape the knitting tube. When it becomes hard, it goes out of the electric furnace and enters the drive shaft to flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com