Hydroisomerization physical separation system for non-standard component oil of petroleum

A technology of hydroisomerization and physical separation, applied in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of social harm, damage to machinery and equipment, unenvironmental protection, etc., and achieves strong applicability and investment. Fewer, quicker effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

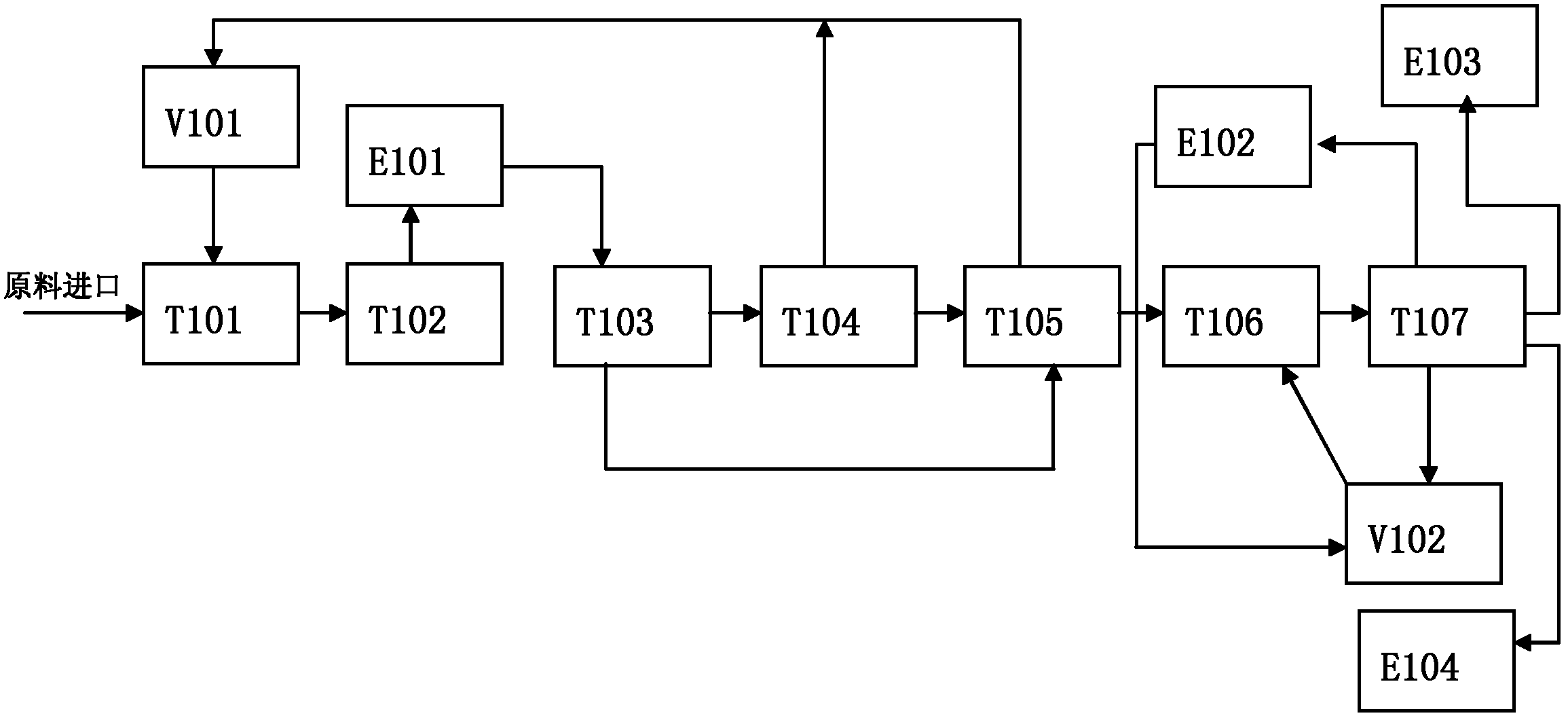

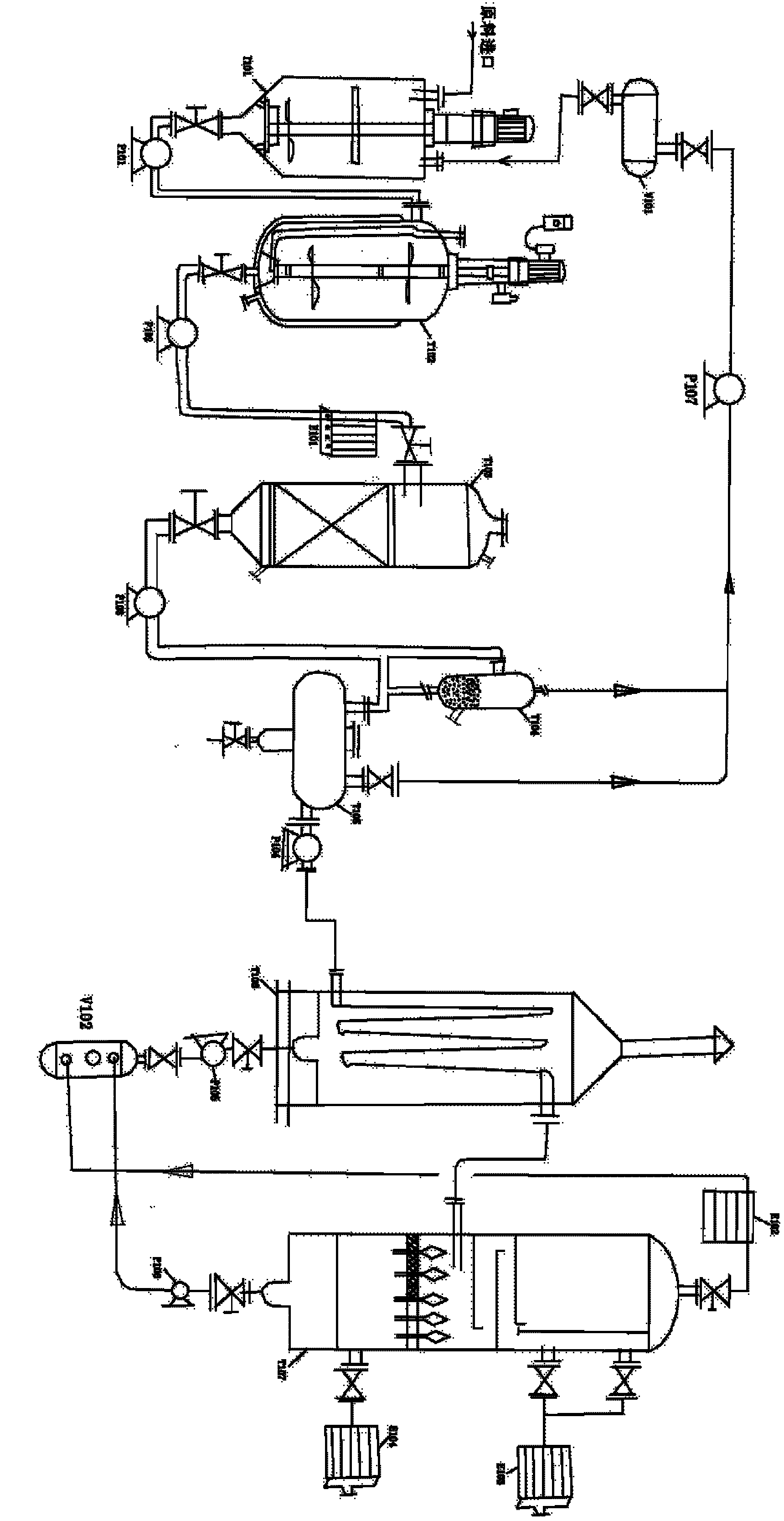

[0008] The present invention will be further described below in conjunction with drawings and embodiments. refer to figure 1 and figure 2 , Petroleum non-standard component oil hydroisomerization physical separation system includes raw material circulation hydrogen-liquid synthesis kettle T101, supplementary hydrogenation liquid synthesis kettle T102, hydrogenation liquid heater E101, reaction kettle T103, gas-liquid separation kettle T104, high separation Kettle T105, heating furnace T106, fractionation still T107, topping gas cooler E102, light component oil cooler E103, medium component oil cooler E104, circulating hydrogen liquid storage tank V101 and tail oil storage tank V102, of which, raw materials The circulating hydrogen liquid synthesis kettle T101 is connected to the supplementary hydrogenation liquid synthesis kettle T102, the supplementary hydrogenation liquid synthesis kettle T102 is connected to the hydrogenation liquid heater E101, the hydrogenation liquid h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com