Method for extracting oil and short-peptide from sesame seeds through aqueous enzymatic method

A water enzymatic method and oil extraction technology, which is applied in the direction of fat oil/fat production, fat production, etc., to achieve the effect of shortening the process route, increasing added value, and increasing supply rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

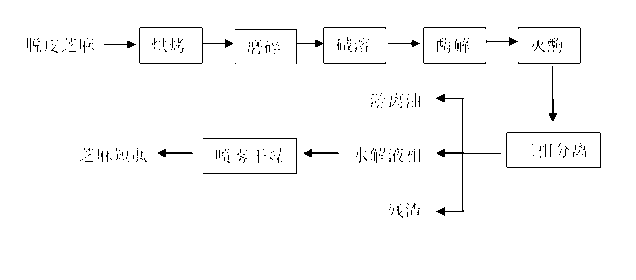

Image

Examples

Embodiment 1

[0031] The peeled sesame seeds are roasted in a roasting machine at a roasting temperature of 160°C and a roasting time of 15 minutes. After baking, the sesame seeds are further ground into a slurry using an emery plate mill. Disperse the sesame pulp in 5 times the weight of water, adjust the pH of the system to 9.5, temperature 55°C, and alkali dissolving time 30min. After the alkali dissolution was completed, 2.0% (w / w) of Protex 6L alkaline protease was added to the system to start enzymatic hydrolysis, and the temperature was maintained at 55°C. After 4h, the temperature of the system was increased to 90°C to inactivate the enzyme (10min). Immediately after the enzyme inactivation, a three-phase decanter is used to separate the system while it is hot to obtain free oil, hydrolyzed liquid phase and residue. After spray drying the hydrolyzed liquid phase, sesame peptide powder is obtained.

[0032] The yield of free oil is 88%, the yield of sesame short peptide is 80%, the pu...

Embodiment 2

[0035] The peeled sesame seeds are roasted in a roasting machine at a roasting temperature of 180°C and a roasting time of 10 minutes. After baking, the sesame seeds are further ground into a slurry using an emery plate mill. Disperse the sesame pulp in 4 times the weight of water, adjust the pH of the system to 9.0, the temperature is 60°C, and the alkali dissolution time is 30 minutes. After the alkali dissolution was completed, 1.5% (w / w) of Protex 6L alkaline protease was added to the system to start enzymatic hydrolysis. The temperature was maintained at 60°C. After 5h, the temperature of the system was increased to 85°C to inactivate the enzyme (20min). Immediately after the enzyme inactivation, a three-phase decanter is used to separate the system while it is hot to obtain free oil, hydrolyzed liquid phase and residue. After spray drying the hydrolyzed liquid phase, sesame peptide powder is obtained.

[0036] The yield of free oil was 86%, the yield of sesame short pepti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap