Anti-large deformation steel for X80 pipeline and production method hereof

A pipeline steel and anti-large deformation technology, which is applied in the field of pipeline steel, can solve the problems of insufficient denaturation ability, time-consuming quenching and tempering heat treatment process, and inability to bear the load, so as to improve low-temperature toughness and structure, and shorten the waiting temperature for rolling. Time, the effect of reducing the cost of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

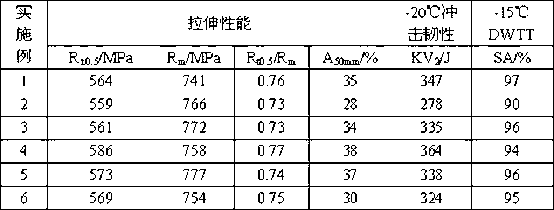

Examples

Embodiment 1

[0038] A large deformation resistant X80 pipeline steel, its composition and weight percentage content are: C: 0.051, Si: 0.26, Mn: 1.89, P: 0.010, S: 0.0010, Ni: 0.01, Mo: 0.34, Cr: 0.26, Cu: 0.02, Nb: 0.056, V: 0.003%, Ti: 0.026%, Al: 0.032, N: 0.0090, Ca: 0.0021, the balance is Fe and inevitable inclusions.

[0039] Production steps:

[0040] 1) Smelting and continuous casting into billets;

[0041] 2) Heating the slab, the temperature is controlled at 1126℃;

[0042] 3) Carry out rough rolling, the end temperature of rough rolling is 973℃, and the reduction rate per pass is 12%;

[0043] 4) For finishing rolling, the start rolling temperature is 885°C, the final rolling temperature is 817°C, and the cumulative reduction ratio is 78.3%;

[0044] 5) Cooling in two stages: the first stage of cooling is cooled to 749°C at a cooling rate of 5.6°C / S, and the second stage of cooling is cooled to 303°C at a cooling rate of 35.3°C / S;

[0045] 6) Straighten after cooling to room temperature in...

Embodiment 2

[0047] A large deformation resistant X80 pipeline steel, its composition and weight percentage content are: C: 0.084, Si: 0.20, Mn: 1.78, P: 0.008, S: 0.0005, Ni: 0.16, Mo: 0.17, Cr: 0.34, Cu: 0.05, Nb: 0.045, V: 0.004%, Ti: 0.013%, Al: 0.022, N: 0.0085, Ca: 0.0012, the balance is Fe and inevitable inclusions.

[0048] Production steps:

[0049] 1) Smelting and continuous casting into billets;

[0050] 2) Heating the slab, the temperature is controlled at 1139℃;

[0051] 3) Carry out rough rolling, the end temperature of rough rolling is 1049℃, and the reduction rate per pass is 13%;

[0052] 4) For finishing rolling, the start rolling temperature is 879°C, the final rolling temperature is 806°C, and the cumulative reduction ratio is 81%;

[0053] 5) Cooling is performed in two stages: the first stage of cooling is cooled to 722°C at a cooling rate of 6.2°C / S, and the second stage of cooling is cooled to 252°C at a cooling rate of 41.4°C / S;

[0054] 6) Straighten after cooling to room te...

Embodiment 3

[0056] A large-deformation resistant X80 pipeline steel, its composition and weight percentage content are: C: 0.059, Si: 0.43, Mn: 1.80, P: 0.007, S: 0.0014, Ni: 0.10, Mo: 0.27, Cr: 0.39, Cu: 0.07, Nb: 0.061, V: 0.002%, Ti: 0.018%, Al: 0.039, N: 0.0077, Ca: 0.0036, the balance is Fe and unavoidable inclusions.

[0057] Production steps:

[0058] 1) Smelting and continuous casting into billets;

[0059] 2) Heating the slab, the temperature is controlled at 1103℃;

[0060] 3) Carry out rough rolling, the end temperature of rough rolling is 1027℃, and the reduction rate per pass is 15.5%;

[0061] 4) For finishing rolling, the start-rolling temperature is 863℃, the final rolling temperature is 795℃, and the cumulative reduction ratio is 75.2%;

[0062] 5) Cooling in two stages: the first stage of cooling is cooled to 743°C at a cooling rate of 6.9°C / S, and the second stage of cooling is cooled to 291°C at a cooling rate of 52.4°C / S;

[0063] 6) Straighten after cooling to room temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com