High energy solid state discharge igniting module

An ignition module, solid-state technology, applied in jet propulsion devices, gas turbine devices, machines/engines, etc., can solve the problems of inconvenient radioactive disposal, large size of ignition devices, and low reliability, and achieve high electrical conversion efficiency and high electrical efficiency. , Electromagnetic compatibility effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

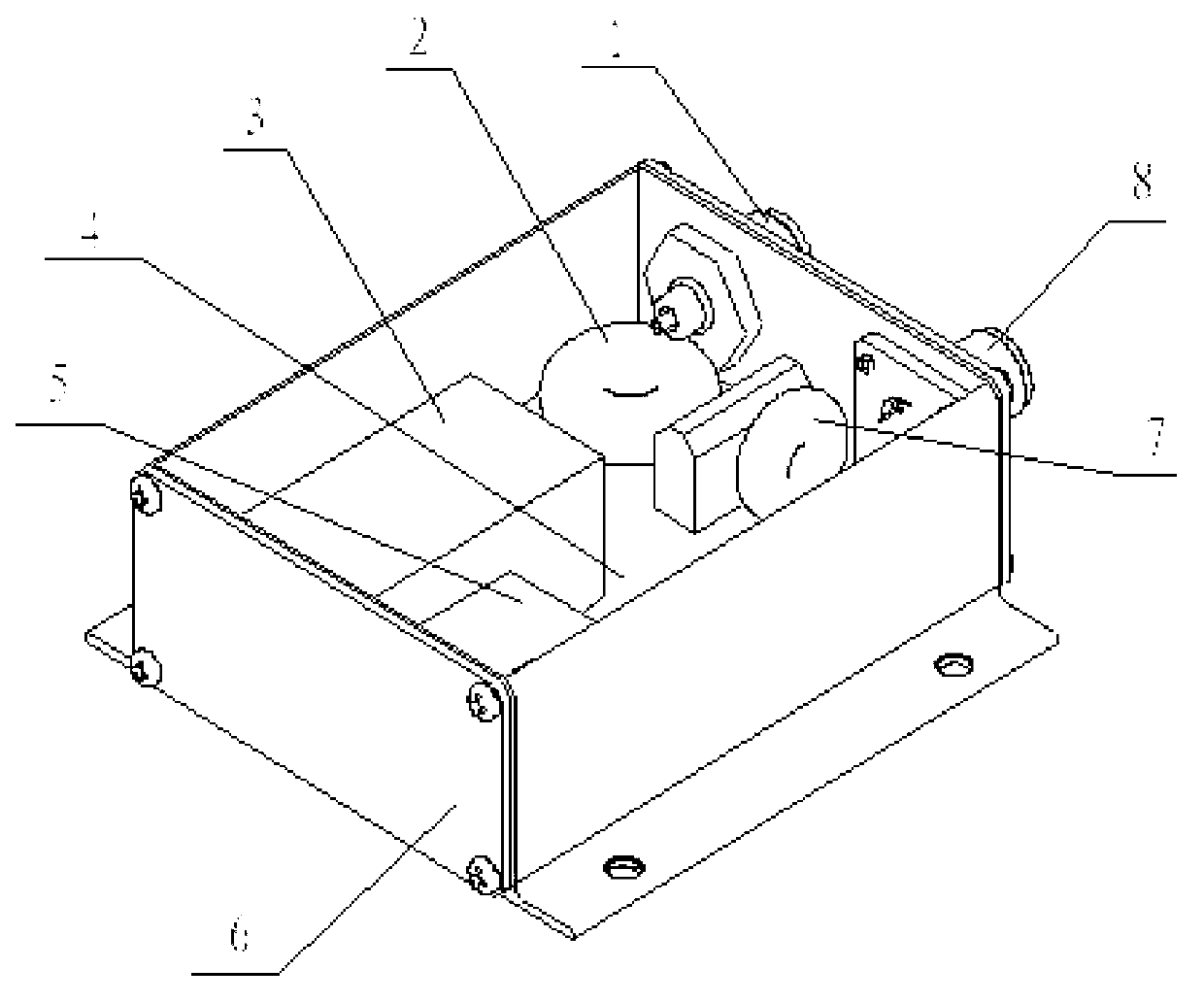

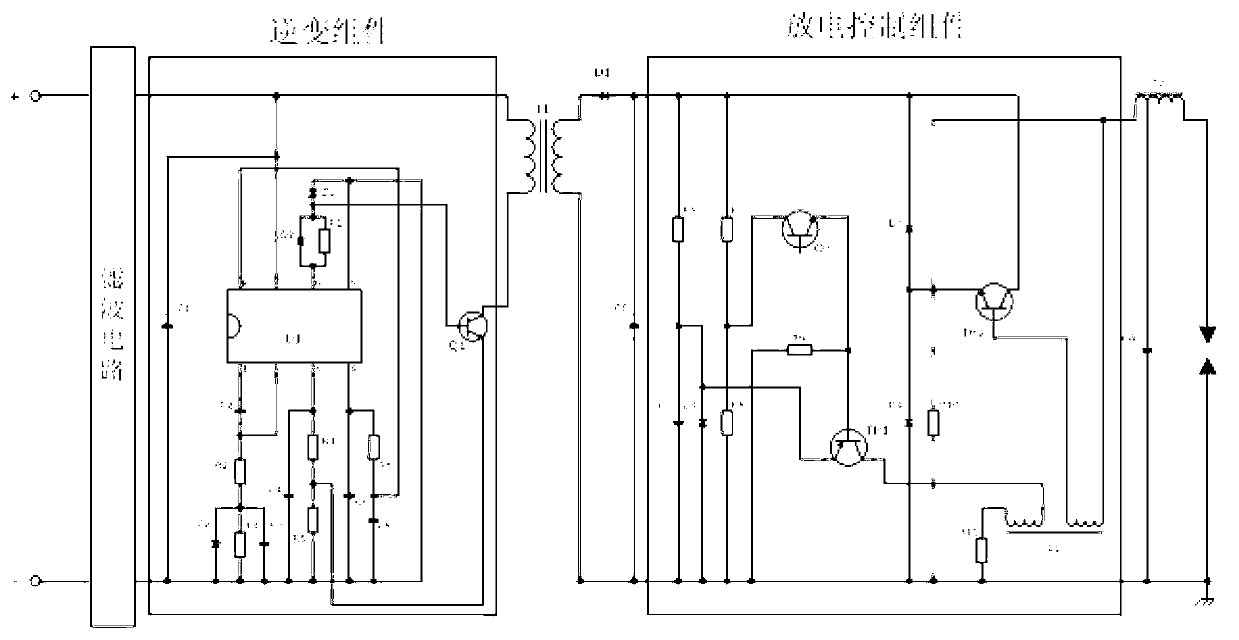

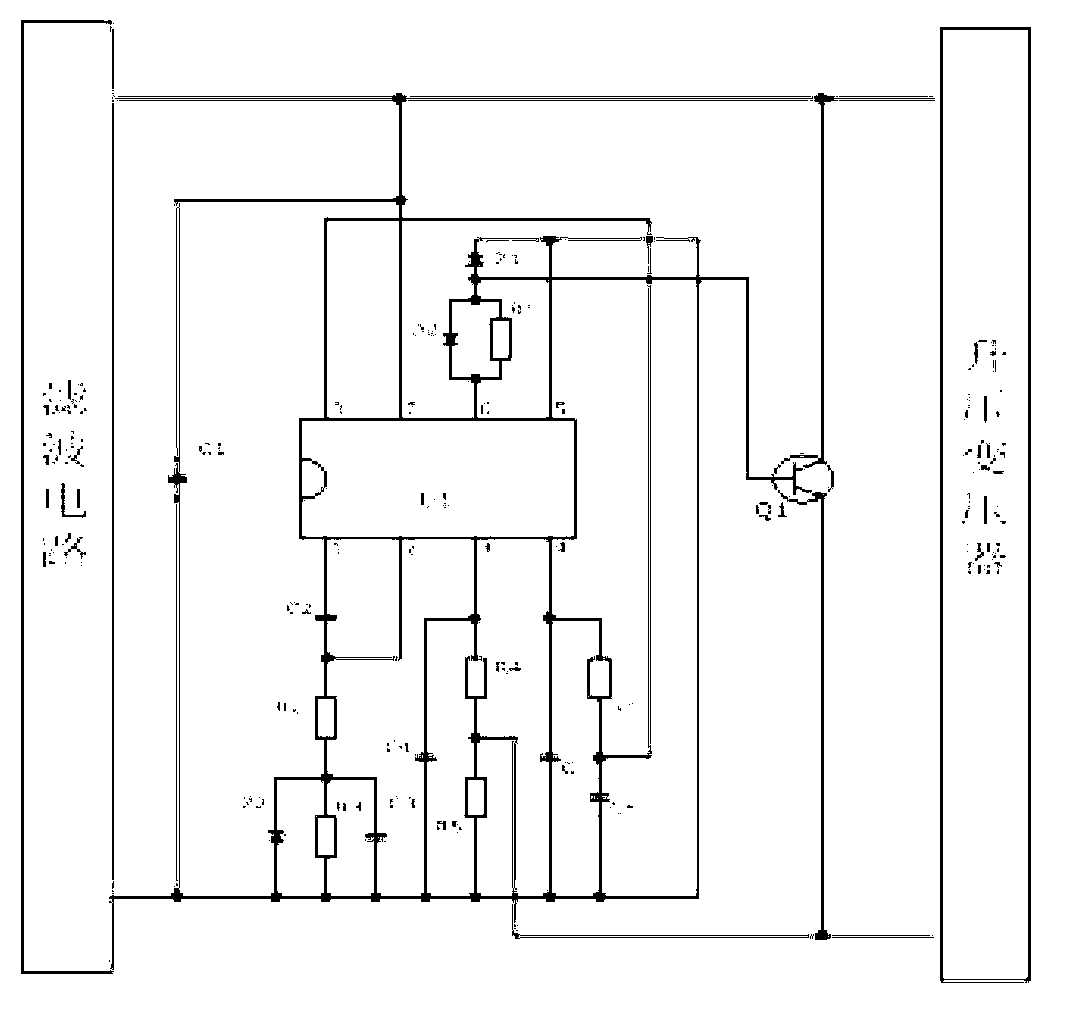

[0015] exist figure 1 In one embodiment described, the high-energy solid-state discharge ignition module is mainly composed of a power input interface 8 and a high-voltage output interface 1 arranged on the same side of the housing assembly 6, and is fixedly connected in the casing of the housing assembly 6, including an inverter assembly, a rectifier The functional circuit board 4 of the component and the discharge control component, the filter 7 electrically connected to the power input interface 8, the step-up transformer 5, the capacitor component 3 and the high-frequency transformer 2 are composed. The inverter circuit composed of the pulse width modulation PWM control chip and its auxiliary circuit is electrically connected between the filter and the step-up transformer. The high-voltage boost circuit composed of the thyristor and its trigger circuit and the high-frequency transformer 2 is electrically connected between the energy storage capacitor assembly 3 and the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com