A weaving point stacking thread detection machine

A detection machine and stacking line technology, which is applied in the direction of electromagnetic measuring devices, electric/magnetic diameter measurement, etc., can solve the problems of product scrapping, reduce manpower waste, avoid product scrapping, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

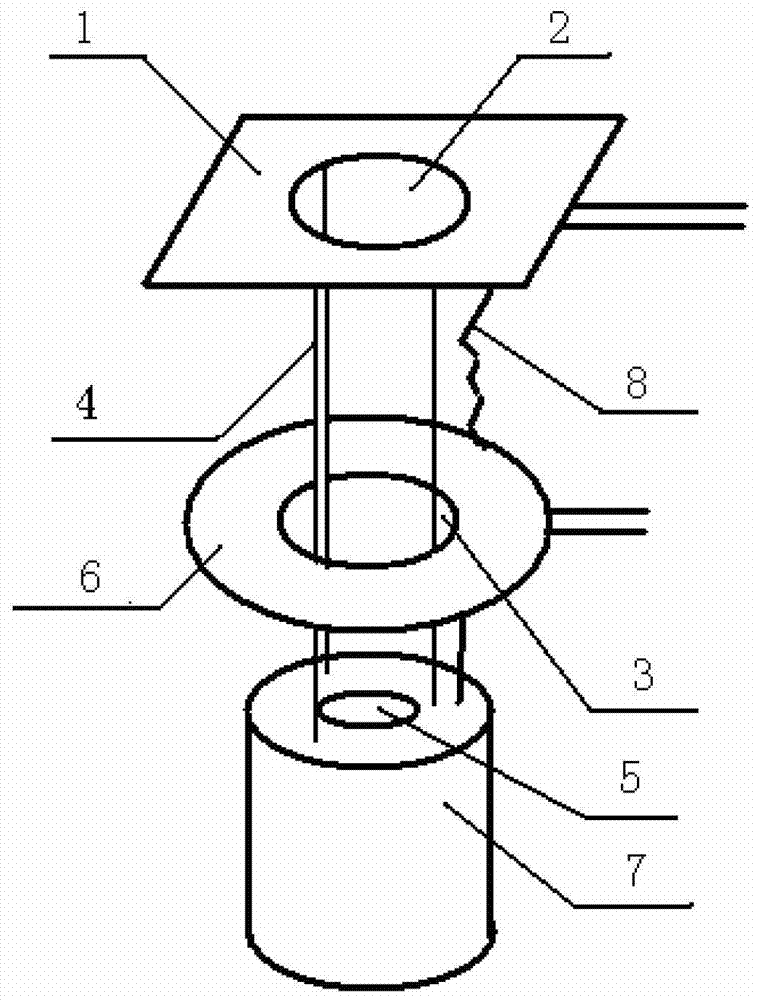

[0019] A braiding point stacking wire detection machine, which is composed of a suspension wire support 1, an insulated suspension wire 4, a detection piece 6, and a trigger device 7. Horizontally parallel, up and down and concentrically hoisted on the suspension wire bracket through the insulated suspension wire, and the upper end surface of the trigger device is 3-5 mm away from the bottom of the detection piece, and the lower end surface is 5-10 mm away from the weaving point.

[0020] Suspension wire support, its center is shaped on suspension wire support wire hole 2.

[0021] There are 3 insulated suspension wires, which are evenly distributed on the suspension wire bracket around the wire hole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com