A thz-band emxt cavity filter based on mems technology

A cavity filter and filter technology, which is applied to waveguide devices, electrical components, circuits, etc., can solve the problems of large insertion loss and difficult processing of waveguide or cavity filters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

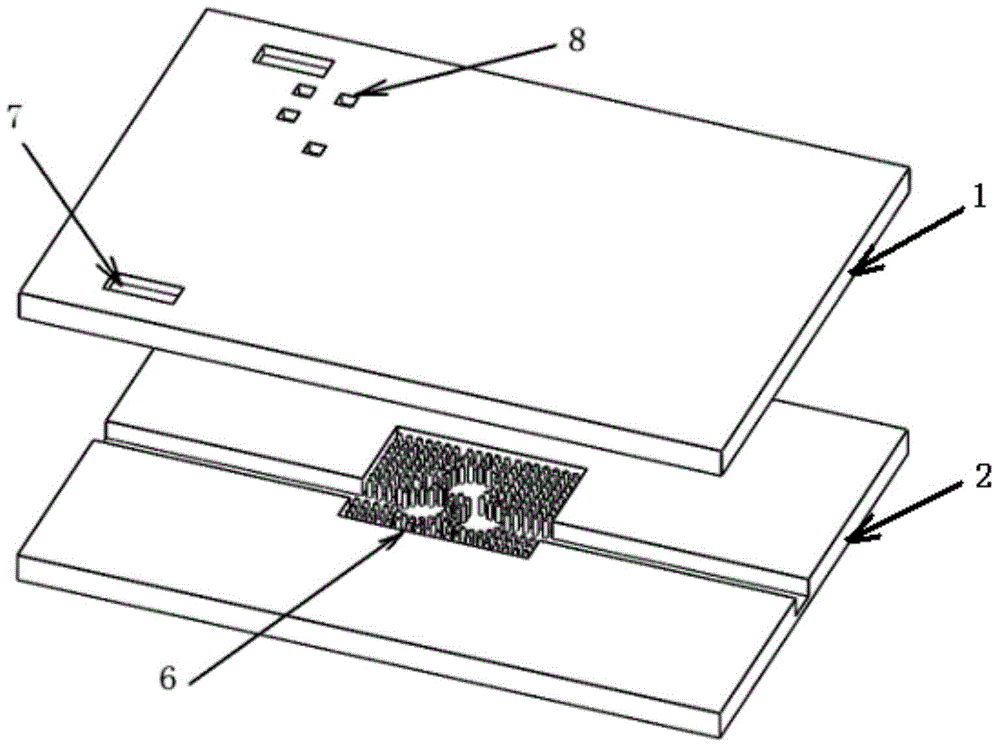

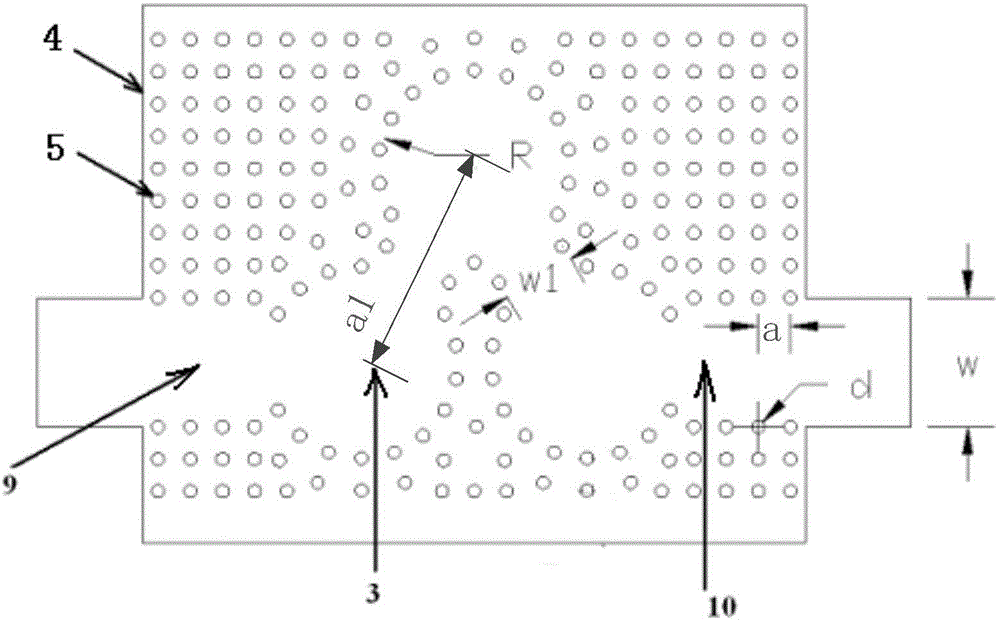

[0025] Such as figure 1 As shown, the THz-band EMXT cavity filter based on the MEMS process includes an upper silicon wafer 1, a lower silicon wafer 2 and a main body 6; the upper silicon wafer 1 is etched with a positioning groove 7 and a Braille mark 8; as figure 2 As shown, the main part 6 includes a PBG structure and a waveguide cavity 4, the PBG structure is composed of silicon pillars 5, and air is filled between the silicon pillars 5; the PBG structure is located in the cavity of the waveguide cavity 4; the surface of the silicon pillar 5 A gold layer is sputtered, and the thickness of the gold layer is 200nm;

[0026] Such as figure 2 As shown, line defects and point defects are introduced into the PBG structure, line defects form PBG waveguides 9 and 10, which are located on the left and right sides of the waveguide cavity 4, and multiple point defects form three resonant cavity structures 3 in the middle;

[0027] The filter can be connected with WR1.9 (483μm×241...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com