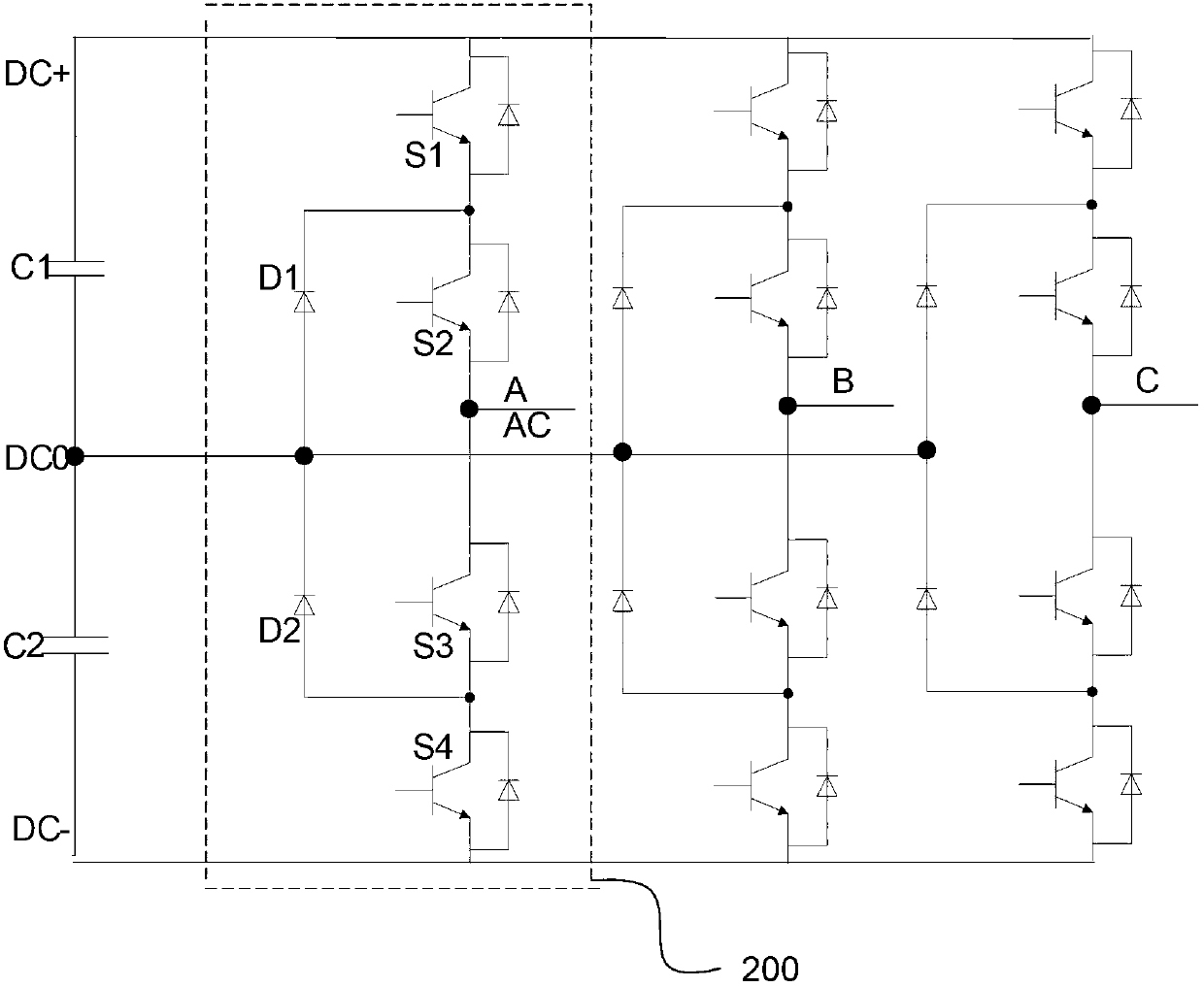

Modularized structure of three-level converter

A three-level, converter technology, applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc., can solve problems such as damage and excessive stray inductance of the commutation circuit, and achieve The effect of ensuring stable operation, improving heat dissipation, and reducing the possibility of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

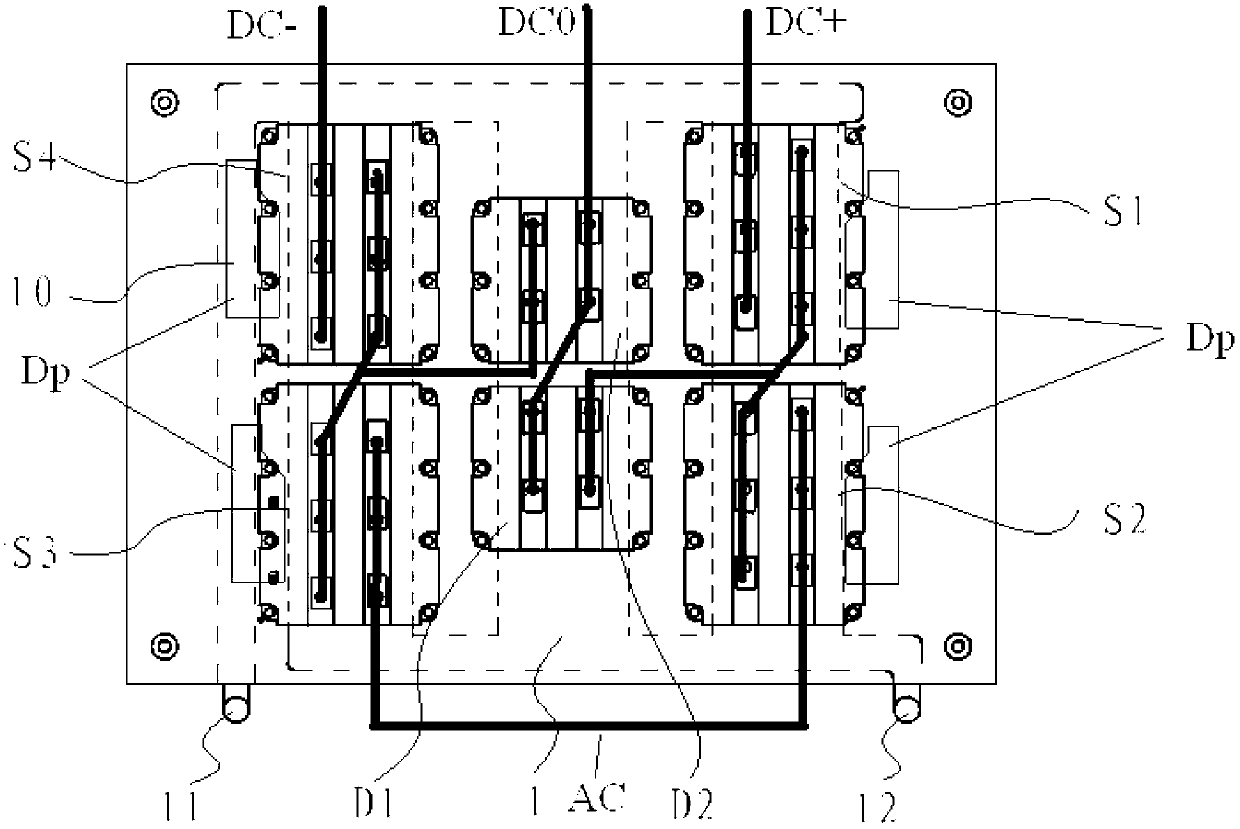

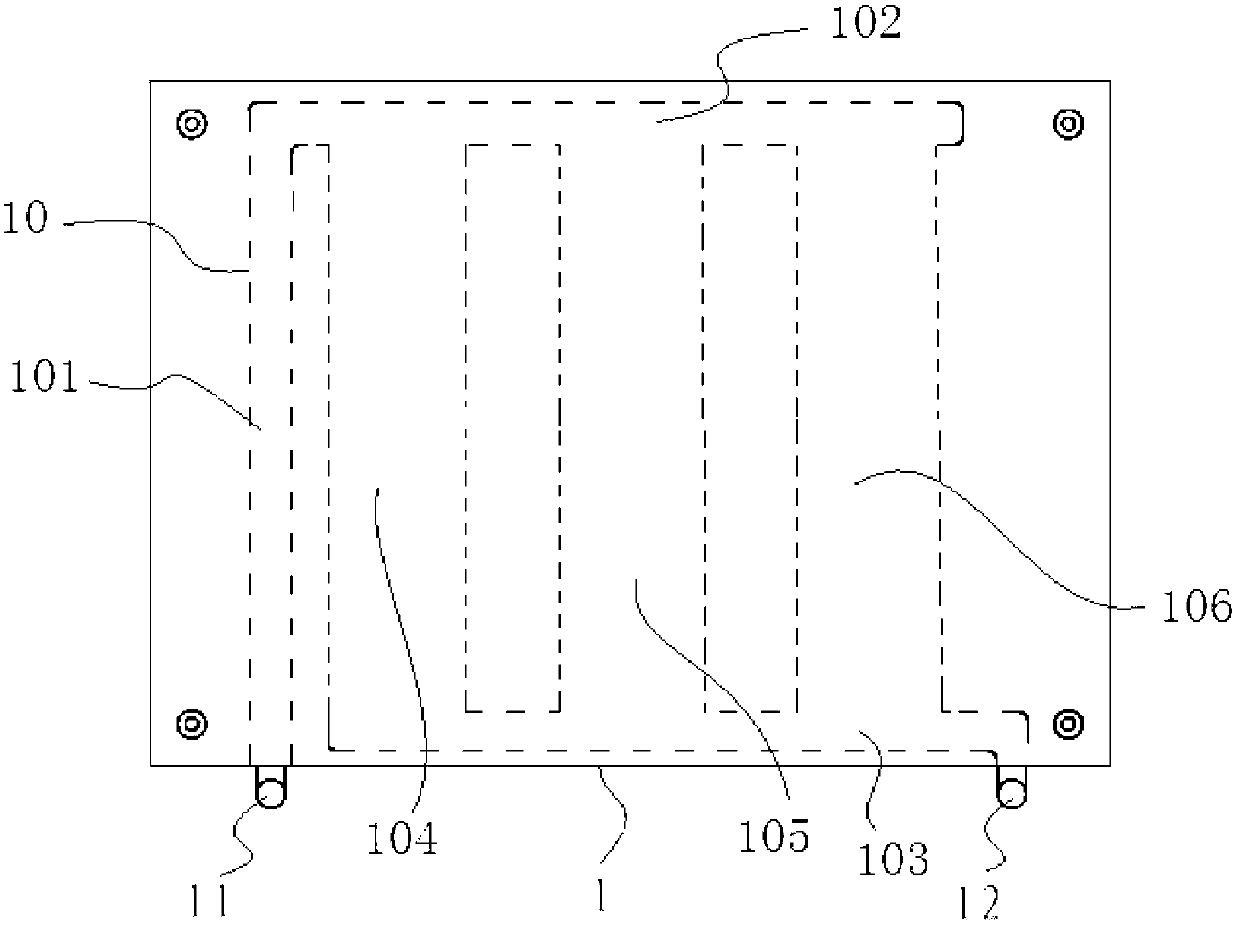

[0051] see figure 2 , is the first specific embodiment of the present invention, wherein the first IGBT S1 is located at the upper right corner of the water-cooled substrate 1; the second IGBT S2 is located at the lower right corner of the water-cooled substrate 1; the third IGBT S3 is located at the lower left corner of the water-cooled substrate 1; The four IGBTs S4 are located in the upper left corner of the water-cooled substrate 1; the first clamping diode D1 is located below the middle of the water-cooled substrate 1; the second clamping diode D2 is located above the middle of the water-cooled substrate 1; therefore, the vertical cooling channel 104 on the left is used The vertical cooling channel 105 in the middle is used for cooling the first and second clamping diodes D1 and D2; the vertical cooling channel 106 on the right is used for cooling the first and second IGBT S1, S2, and the cooling water first flows through the bottom of the first and fourth IGBT S1, S4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com