Drum spike-tooth type remnant film recycling machine

A recovery machine and drum technology, applied in the field of agricultural machinery, can solve the problems of low recovery rate of residual film and high power consumption, and achieve the possible effect of reliable film removal process and reducing soil congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings. The present invention is not limited to the following examples.

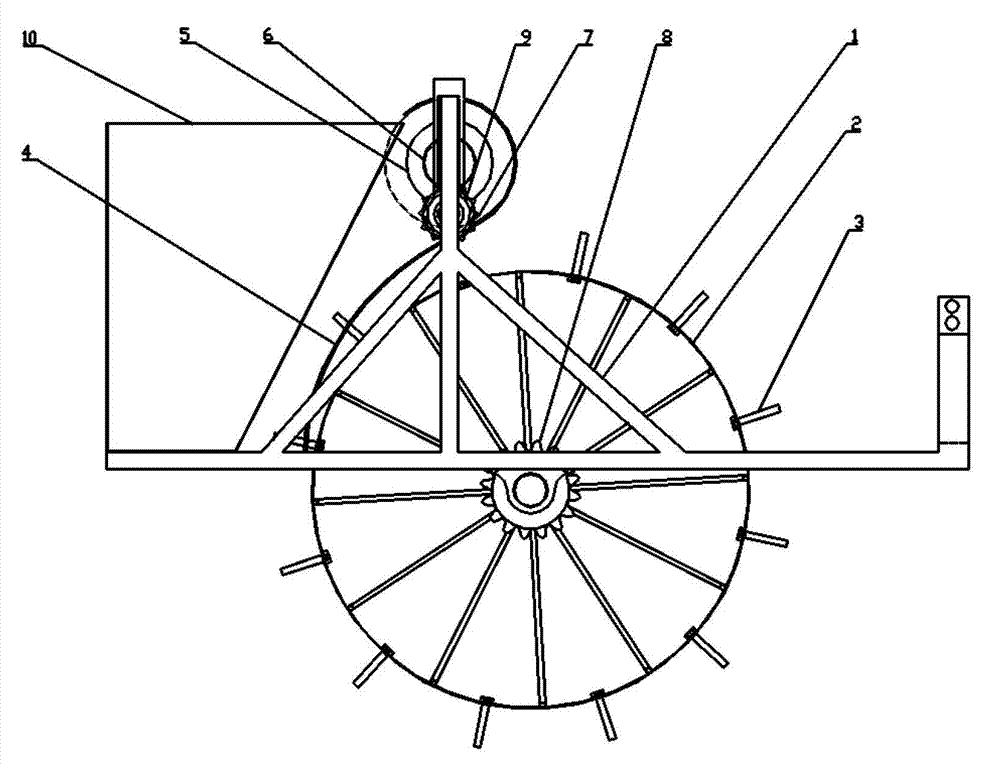

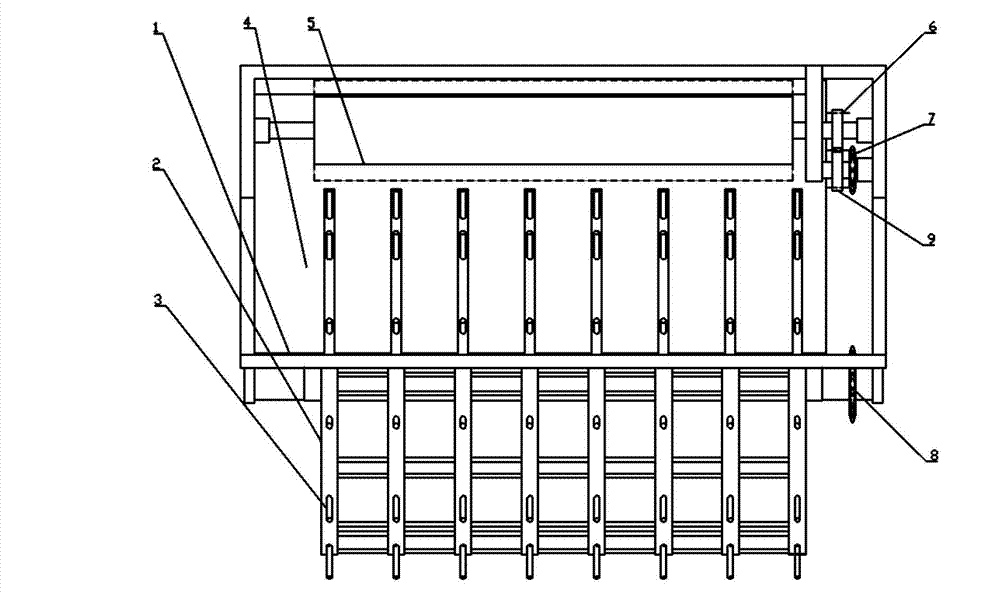

[0028] Such as figure 1 Shown is a schematic structural view of a drum spike type residual film recovery machine of the present invention; figure 2 Its partial rear view schematic diagram. Wherein, the traction frame 1 with the film collecting box 10 is articulated with the traveling machine of peripheral equipment, and the drum 2 is installed on the traction frame 1 and can roll forward. In this embodiment, the drum 2 adopts a cage drum, which is a cylindrical cage structure welded by steel bars and steel strips, so that the soil attached to the upper surface of the mulch can leak through the gap of the cage when the mulch is rolled up, reducing the risk of detachment. The possibility of the membrane structure being blocked by soil makes the stripping process rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com