Method for mixed application of sodium silicate binder and polyving akohol

A polyvinyl alcohol, mixed application technology, applied in the petroleum industry, solid fuel, fuel and other directions, can solve the problems of poor water resistance, poor water resistance, unsatisfactory water resistance, etc., and achieve the effect of improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

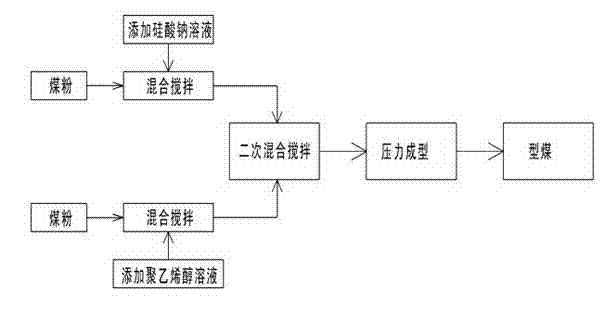

[0013] The present invention will be further described below through embodiments in conjunction with the accompanying drawings.

[0014] In the embodiment, the method of mixing and applying the binder sodium silicate and polyvinyl alcohol includes the following process: ① Add the sodium silicate solution and the polyvinyl alcohol solution to the respective loose materials independently, and mix and stir them separately to form The loose material containing sodium silicate and the loose material containing polyvinyl alcohol; ② Mix the above-mentioned loose material containing sodium silicate and the loose material containing polyvinyl alcohol together, and perform secondary stirring to become a mixed loose material; ③ Then The mixed loose materials are sent to the press for pressure molding.

[0015] More specific process steps: the loose material is coal powder, the particle size is less than 6 mm, sodium silicate (water glass, sodium silicate) solution and polyvinyl alcohol s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com