Pneumatic arc striking device for vacuum cathode arc evaporation source

A technology of cathodic arc evaporation and arc striking device, which is applied in vacuum evaporation coating, ion implantation coating, metal material coating process, etc. The effect of air leakage, reducing defective product rate and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

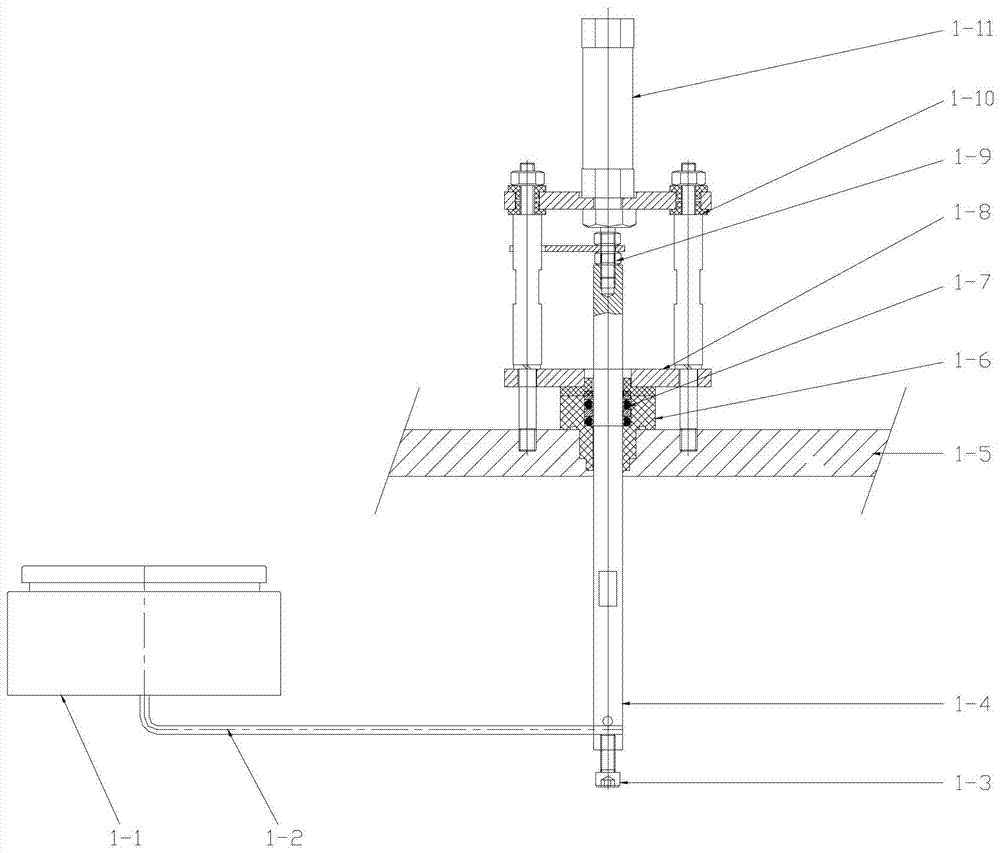

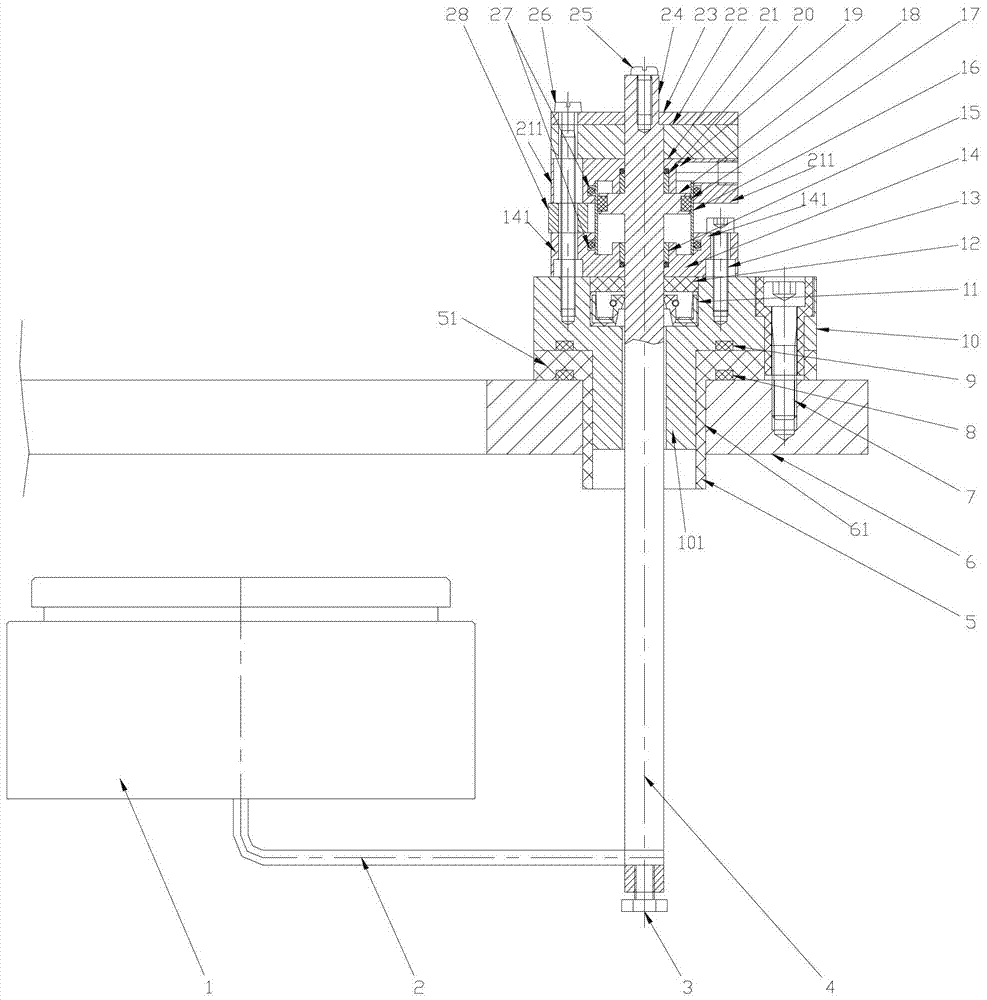

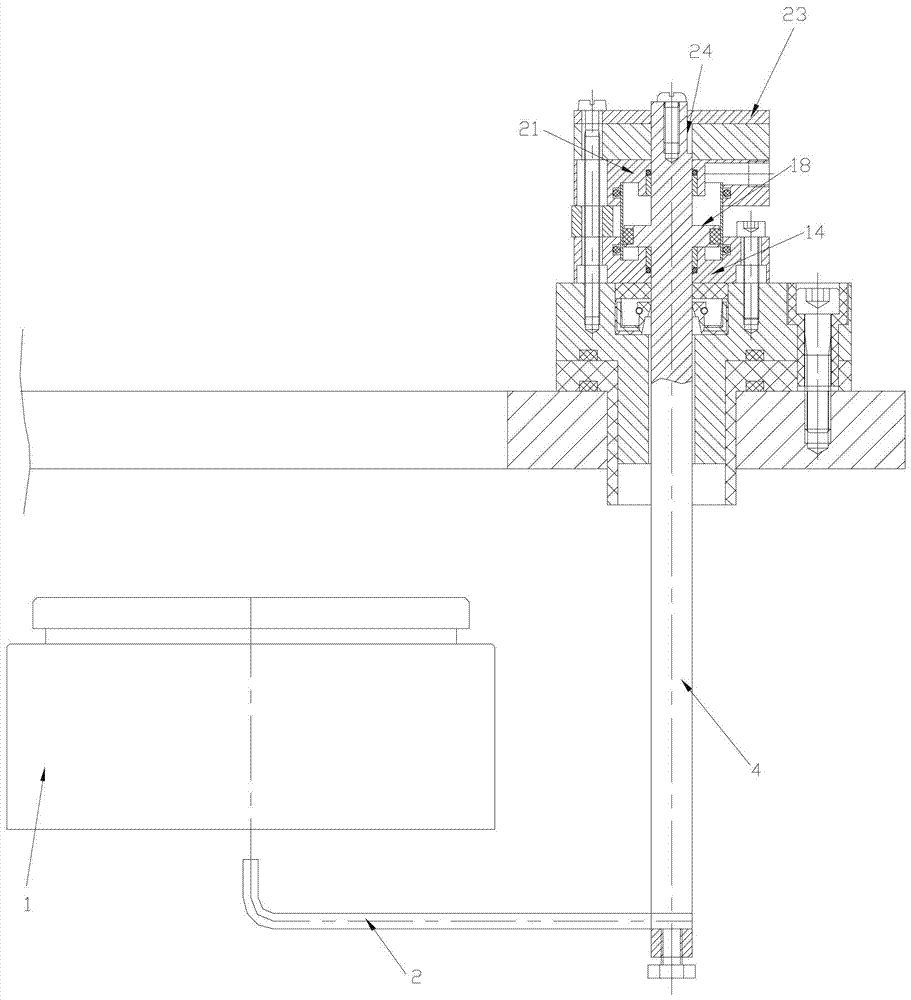

[0028] The pneumatic arc striking device of the vacuum cathode arc evaporation source of the preferred embodiment of the present invention, such as figure 2 , 3 , 4 referred to as arc ignition device includes arc ignition needle 2, piston rod 4, rigid arc ignition base 10, sealing insulation 5, dynamic seal 11, dynamic sealing pressure pad 12, piston assembly support, anti-rotation plate 23. The arc starter base 10 can also be made of other metal materials, such as copper and the like.

[0029] The piston rod 4 is integrally processed by the piston extension rod at the front end and the piston assembly at the rear end. In this way, it is possible to avoid the position deviation of the arc striking needle 2 or the increased distance between the arc striking needle 2 and the surface of the target block 1 due to the loose connection between the piston extension rod and the piston assembly in the prior art. The elbow cannot be in contact with the surface of the target block 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com