Dyeing circulation system

A circulating system and circulating tube technology, applied in the field of dyeing circulating system, can solve the problems of inability to meet the growing demand of production, simple structure, etc., and achieve the effects of increasing air tightness, improving uniformity, and increasing rotating force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

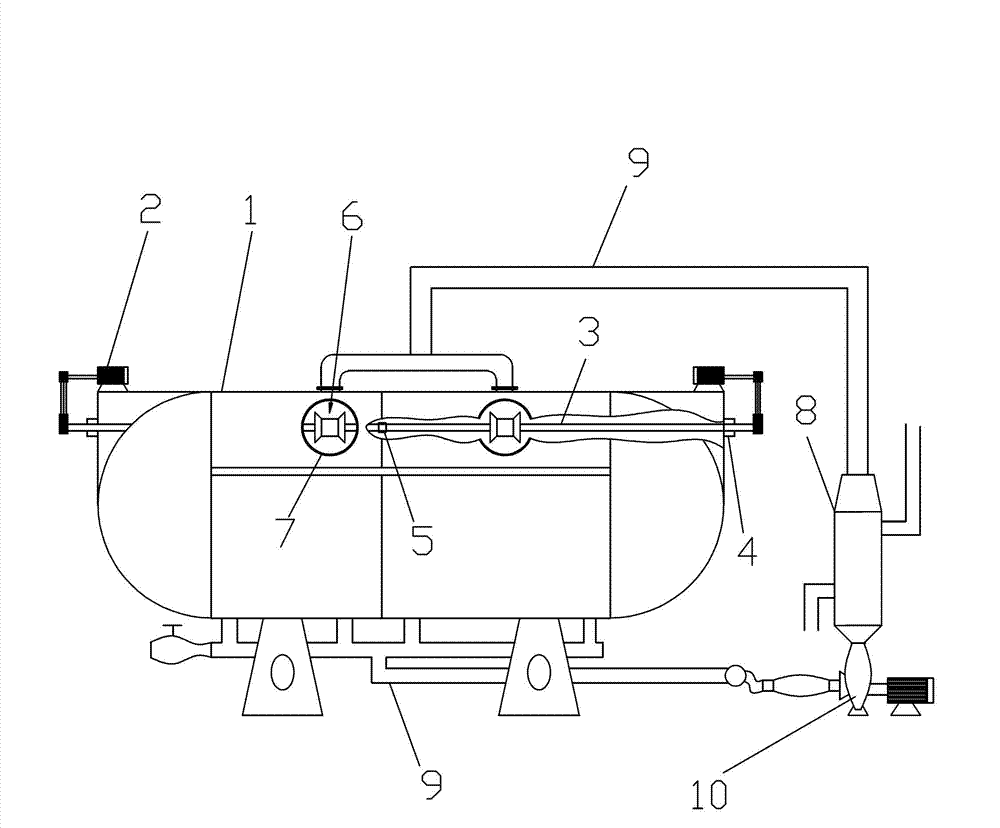

[0029] As shown in the figure, a dyeing circulation system disclosed by the present invention includes a machine cylinder 1, a cloth guiding device, a cold heat exchanger 8, a circulation pipe 9, and the cold heat exchanger 8 and the machine cylinder 1 are connected by a circulation pipe 9 A circulating structure is formed; the circulating water pump 10 sends the dye into the cold heat exchanger 8, and the dye enters the machine cylinder 1 through the action of high-temperature water vapor.

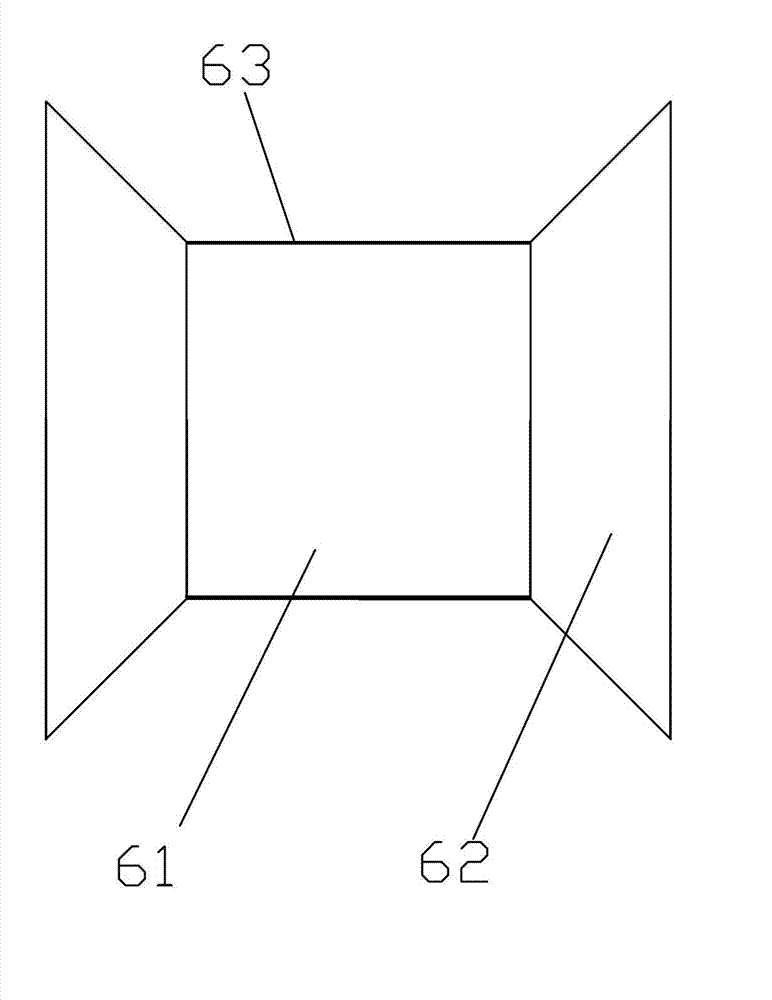

[0030] The cloth guide device includes a motor 2 arranged outside the machine cylinder 1, a cloth guide shaft 3 running through the machine cylinder 1, a mechanical seal 4, and a fixing frame 5; the motor 2 includes two, which are respectively linked with one end of the cloth guide shaft 3; The cloth shaft 3 and the cylinder 1 are connected by a mechanical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com