Oil field underground liquid level detection method and device

A technology for liquid level detection and oil field wells, which is applied in construction and other fields, can solve the problems of increasing oil production costs, failing to measure reflected waves, and misjudgment of the state of oil barrels touching liquid, etc., to achieve improved oil recovery efficiency, easy implementation, and simple devices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

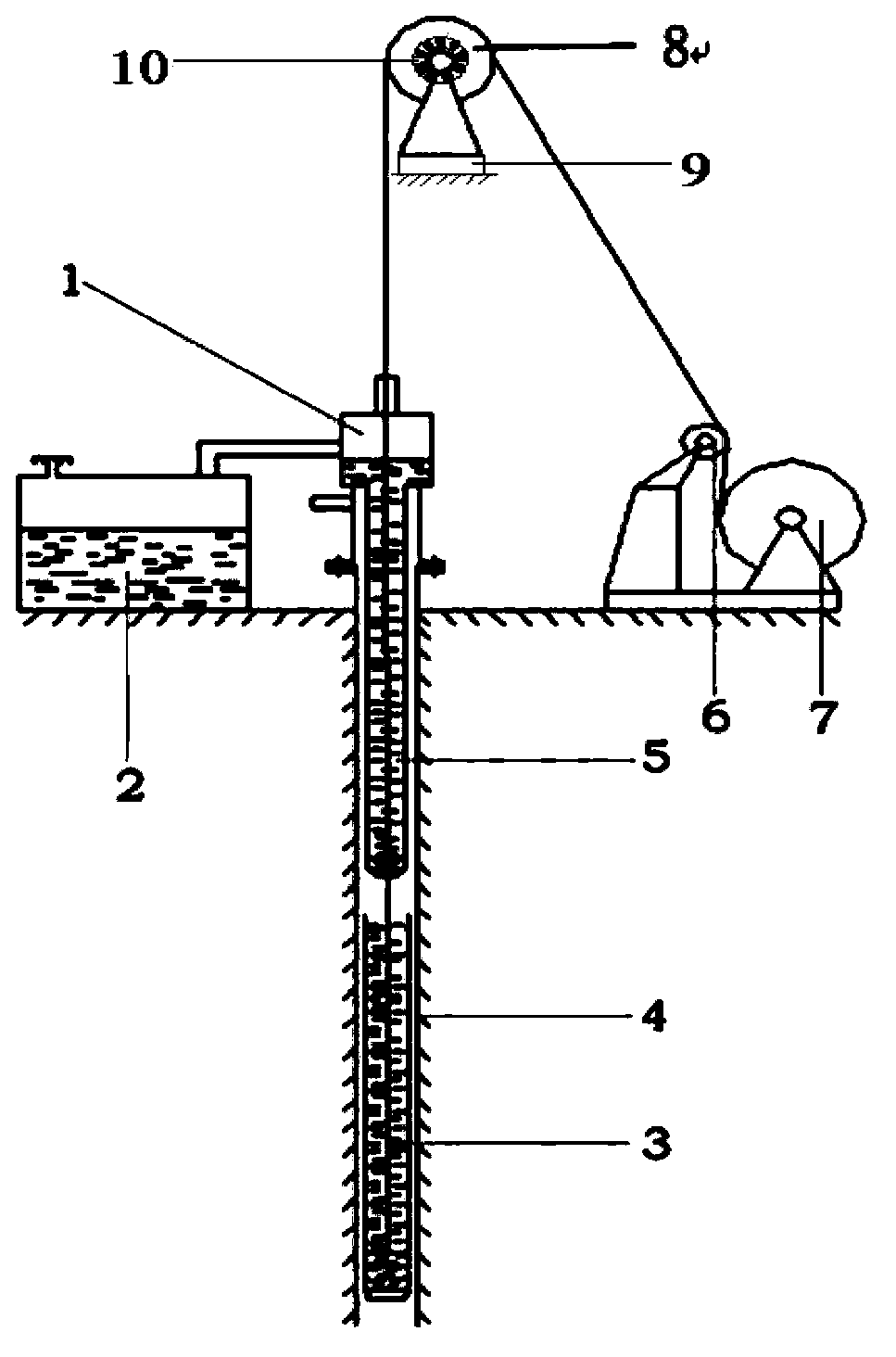

[0037] The method, device and working principle of the present invention are further described below with reference to design examples and accompanying drawings.

[0038] as attached figure 1 As shown, the process of oil production in the oil field is as follows: the lifting mechanism 7 and the rope discharger 6 control the retraction and release of the wire rope, the wire rope is directly connected to the oil fishing barrel 3 through the guide sheave 8, and the oil fishing barrel 3 is controlled to go up and down, and the oil passes through the fishing oil barrel. 3. The bottom one-way valve enters the oil drum, and the produced oil enters the oil guide pipe 5 through the one-way valve, and finally enters the oil storage tank 2 through the wellhead device 1.

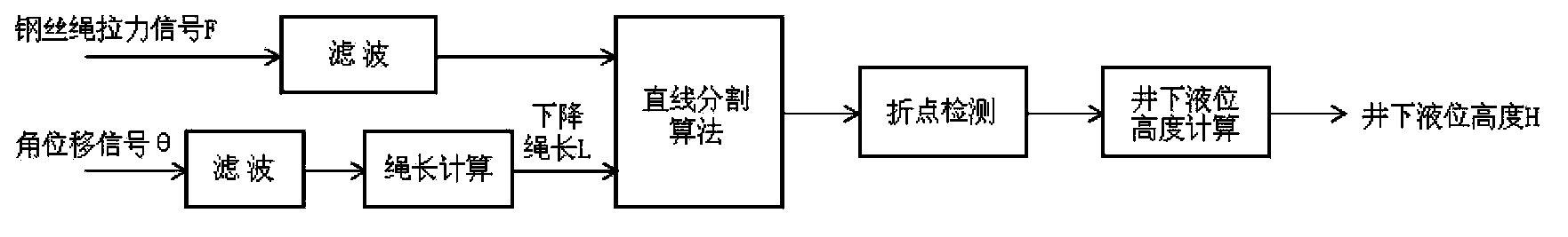

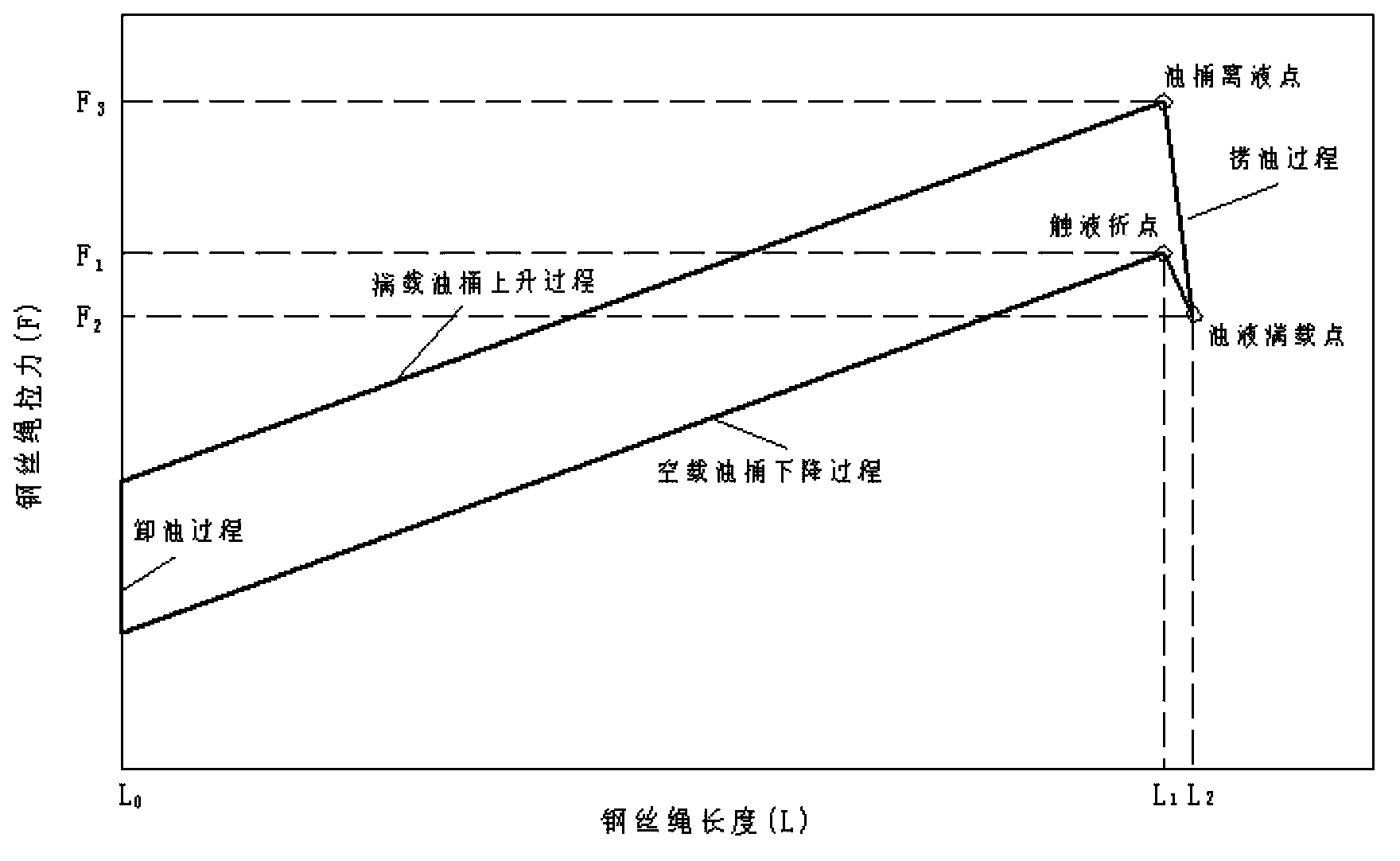

[0039] The oilfield downhole liquid level detection method provided by the present invention specifically comprises the following steps:

[0040] The first step is to place the empty fishing oil barrel under the wellhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com