Mass flow heavy oil pulverization spray gun suitable for burning of low nitric oxides (NOx)

A technology of atomizing spray gun and large flow rate, which is applied in the direction of burners, lighting and heating equipment, etc. It can solve the problem of incomplete combustion of heavy oil, achieve the effect of reducing NOx emission, reducing NOx emission and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

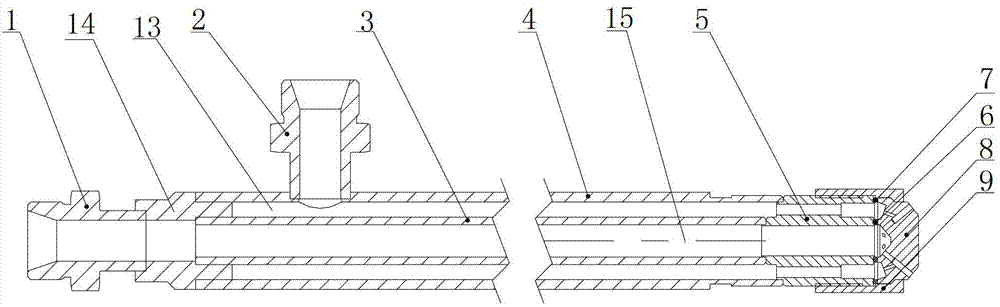

[0030] figure 1 It is a structural schematic diagram of a large flow heavy oil atomizing spray gun suitable for low NOx combustion, including the gun body assembly and nozzle assembly,

[0031] The gun body assembly includes an inner sleeve 3, an air interface 1 communicating with the inner sleeve 3, an outer sleeve 4, a liquid interface 2, and a rectifier 5. One end of the inner sleeve 3 and the outer sleeve 4 is fixedly connected by a plug 14, and the inner sleeve 3 is fixedly connected to the outer sleeve 4. A steam channel 15 is formed in the casing, a heavy oil flow channel 13 is formed between the inner casing 3, the outer casing 4 and the plug 14, the liquid circuit interface 2 communicates with the heavy oil flow channel 13 through the outer casing 4, and the inner casing 3 and the outer casing 4 The other end of the rectifier is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com