System and method for oxidizing flue gas NO by ultrasonic atomization of hydrogen peroxide

A technology of ultrasonic atomization and hydrogen peroxide, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of low NO efficiency and invalid decomposition, and achieve good effect, improved efficiency, and high atomization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

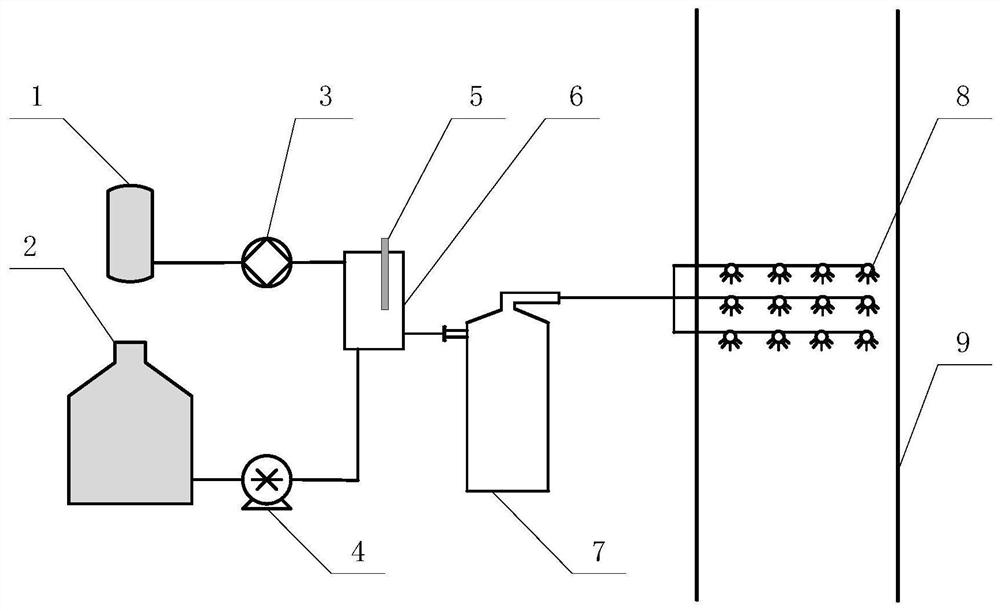

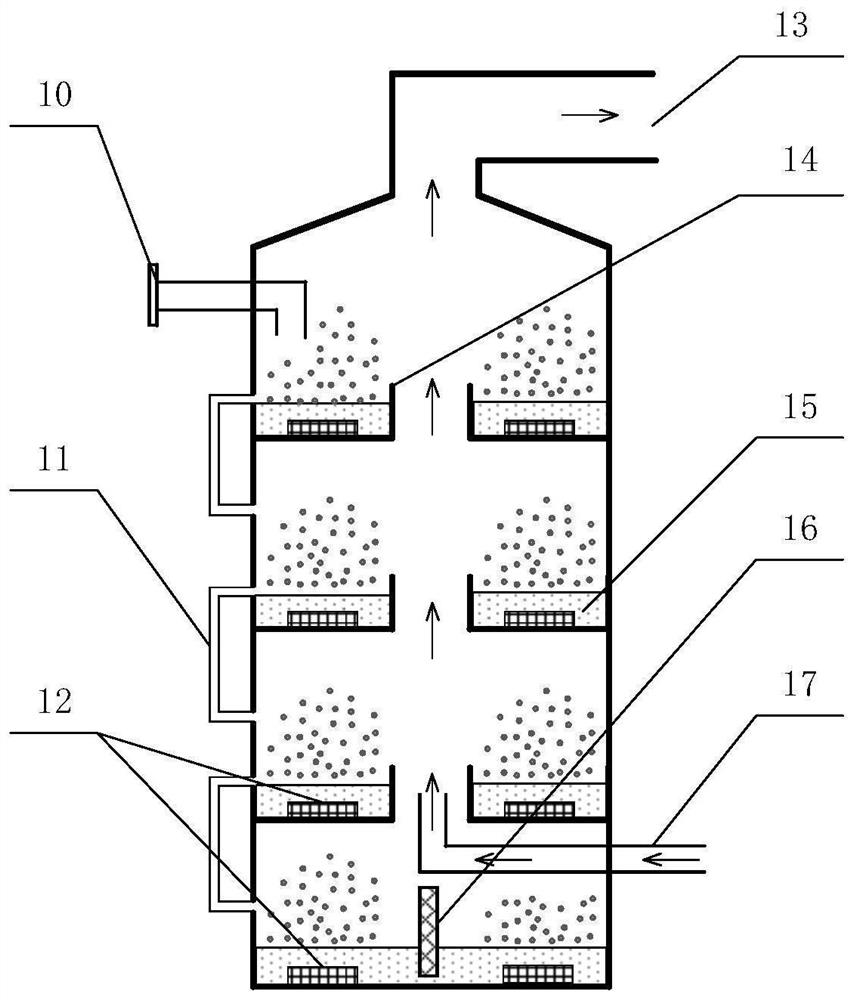

[0038] A hydrogen peroxide ultrasonic atomization oxidation flue gas NO system of the present invention, such as figure 1 As shown, it includes an alkali storage tank 1, a hydrogen peroxide storage tank 2, an alkali metering pump 3, a hydrogen peroxide delivery pump 4, a pH meter 5, a mixing tank 6, a hydrogen peroxide ultrasonic atomizer 7, a spray grid 8, and a flue 9; The outlet of the alkali storage tank 1 is connected to the inlet of the alkali metering pump 3, the outlet of the alkali metering pump 3 is connected to the mixing tank 6, the pH meter 5 is installed on the mixing tank 6, the outlet of the hydrogen peroxide storage tank 2 is connected to the inlet of the hydrogen peroxide delivery pump 4, and the outlet of the hydrogen peroxide delivery pump 4 Connect the mixing tank 6, the outlet of the mixing tank 6 is connected to the inlet of the hydrogen peroxide ultrasonic atomizer 7, the top outlet of the hydrogen peroxide ultrasonic atomizer 7 is connected to the spray...

Embodiment 2

[0055] In this preferred embodiment, the concentration of NO in the flue gas is 150mg / m 3 , the lye tank 1 is sodium hydroxide with a concentration of 1%, and the pH value in the mixing tank 6 is adjusted by the alkali metering pump 3 to about 8, and the hydrogen peroxide atomization pool 15 in the hydrogen peroxide ultrasonic atomizer 7 is arranged in five layers. Ultrasonic atomizing plate 12 adopts ceramic glaze atomizing sheet, and each layer of ultrasonic atomizing plate 12 is connected to the shell by a wire. The height is 8cm, the concentration of hydrogen peroxide in the hydrogen peroxide storage tank 2 is 20%, the molar ratio of the atomized amount of hydrogen peroxide to NO in the flue gas is 2, and the compressed air carries ultrasonically atomized hydrogen peroxide droplets through the spray grid 8 In flue gas at 200°C, the oxidation efficiency of NO is 96%.

Embodiment 3

[0057] In this preferred embodiment, the concentration of NO in the flue gas is 200mg / m 3 , the lye tank 1 is ammonia water with a concentration of 1%, and the pH value in the mixing tank 6 is adjusted to about 6 through the alkali metering pump 3. The atomizing plate 12 adopts a ceramic glaze atomizing sheet, and each layer of ultrasonic atomizing plate 12 is connected to the shell by a wire. The concentration of hydrogen peroxide in the hydrogen peroxide storage tank 2 is 10%, the molar ratio of the atomized amount of hydrogen peroxide to NO in the flue gas is 1.4, and the compressed air carries the ultrasonically atomized hydrogen peroxide droplets through the spray grid 8 into the 350°C In the flue gas, the oxidation efficiency of NO is 98.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| oxidation efficiency | aaaaa | aaaaa |

| oxidation efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com