Gas-assisted atomizing nozzle of atomization hyperviscous fluid

A gas-assisted, atomizing nozzle technology, applied in lighting and heating equipment, burners, etc., can solve the problems of atomization quality deterioration, poor economy, incomplete combustion, etc., to improve combustion efficiency and burnout degree, and meet operating requirements Environmental requirements, the effect of reducing the gas consumption of the factory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the drawings and specific embodiments:

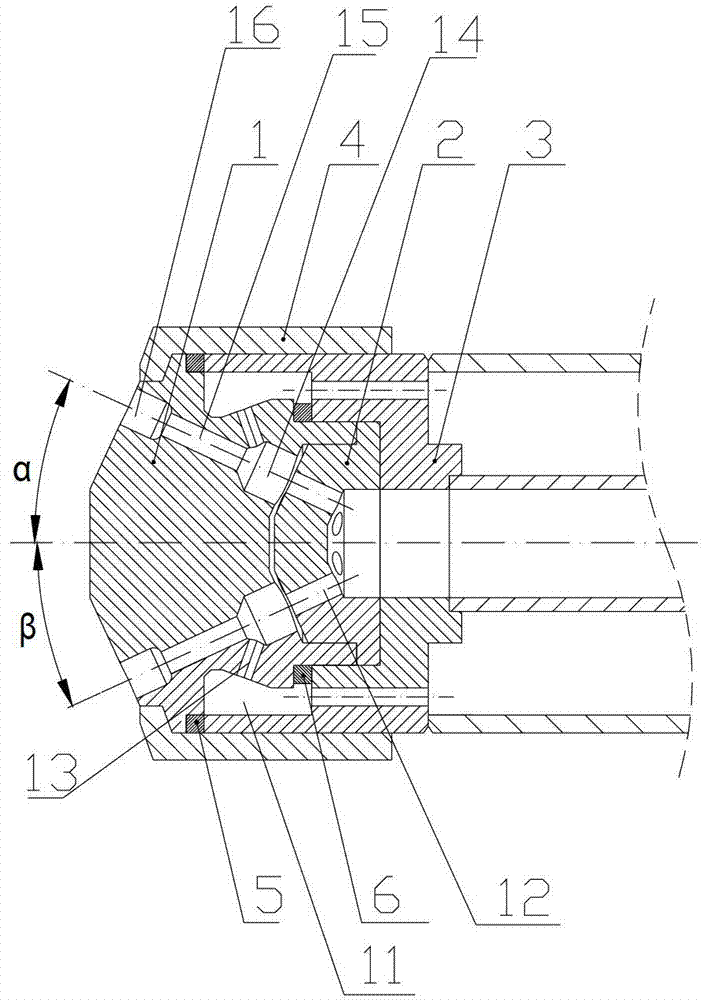

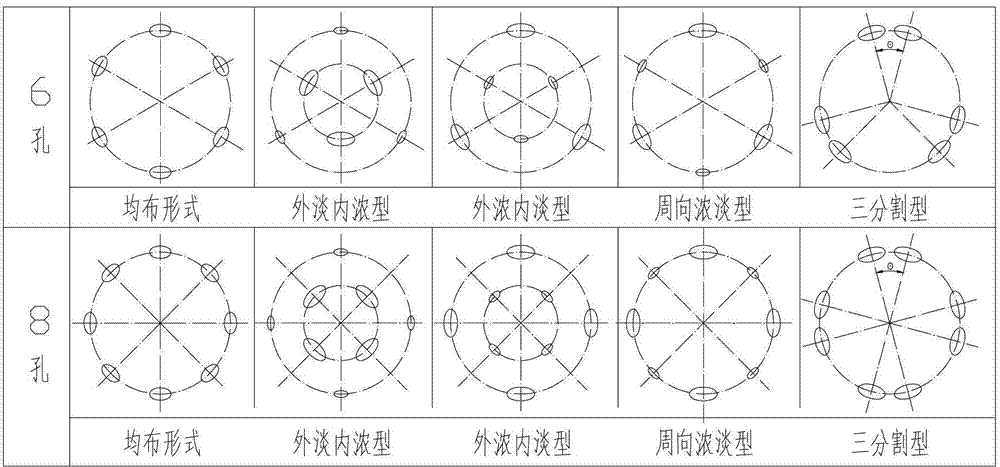

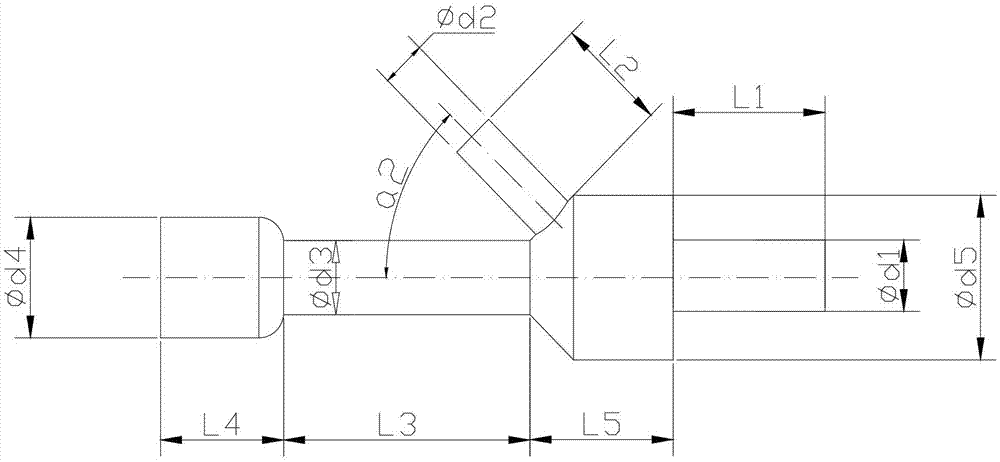

[0028] figure 1 It is a structural diagram of a gas-assisted atomization nozzle for atomizing high-viscosity fluids of the present invention. It includes a nozzle 1, a restrictor cone 2, a gas-liquid distributor 3, and a lock nut 4. The gas-liquid distributor includes a central atomization The gas pipeline and the high-viscosity liquid pipeline covering the periphery of the atomization gas pipeline; the lock nut seals and presses the nozzle on the outlet end of the gas-liquid distributor, and the nozzle presses the restrictor cone plate on the outlet end of the atomization gas pipe , The restrictor cone 2 is provided with a plurality of air holes 12, and the nozzle is provided with a plurality of mixing units with the same number as the air holes. The mixing unit includes a liquid hole 13, a premixing cavity 14, a mixing section 15 and a secondary mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com