Precise assembling structure of static capacitance type adjustable final motion gyroscope

A static capacitance and adjustable technology, applied in the direction of rotating gyroscope, etc., can solve the problems of complicated wiring of micro-tuning gyroscope interface circuit and non-adjustable static capacitance value, so as to simplify the input interface of carrier and bias signal and improve anti-interference. ability, the effect of simplifying the interface circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

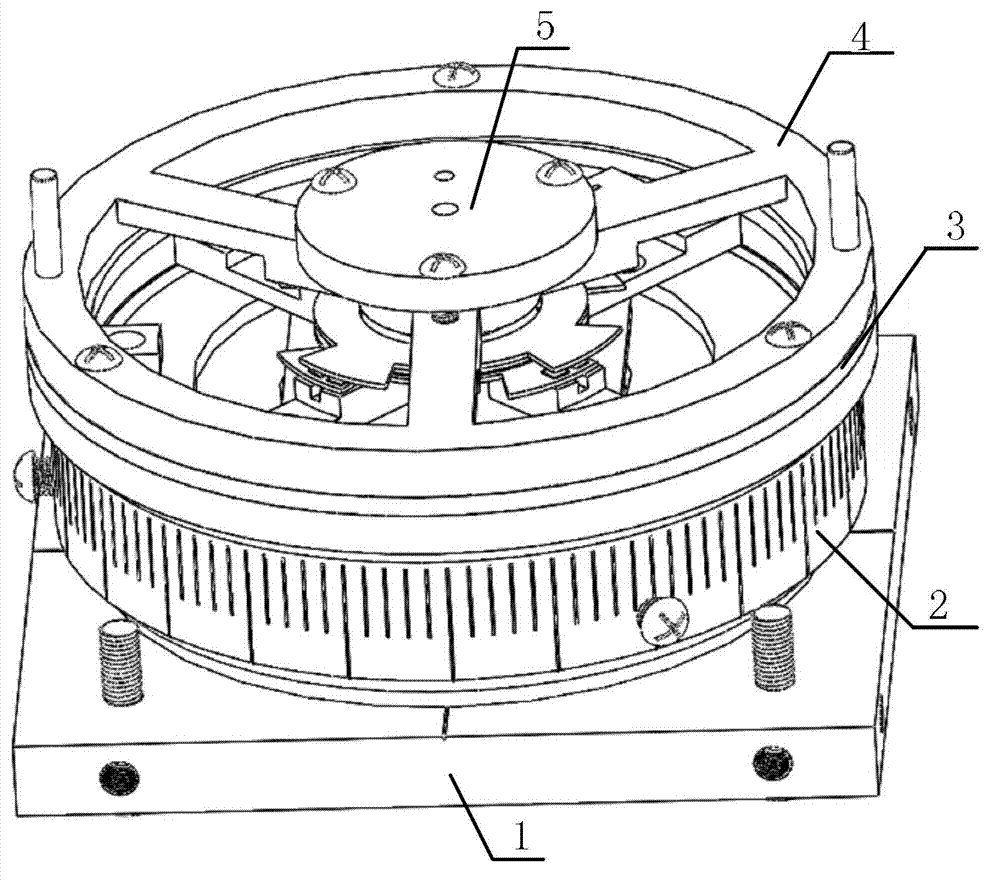

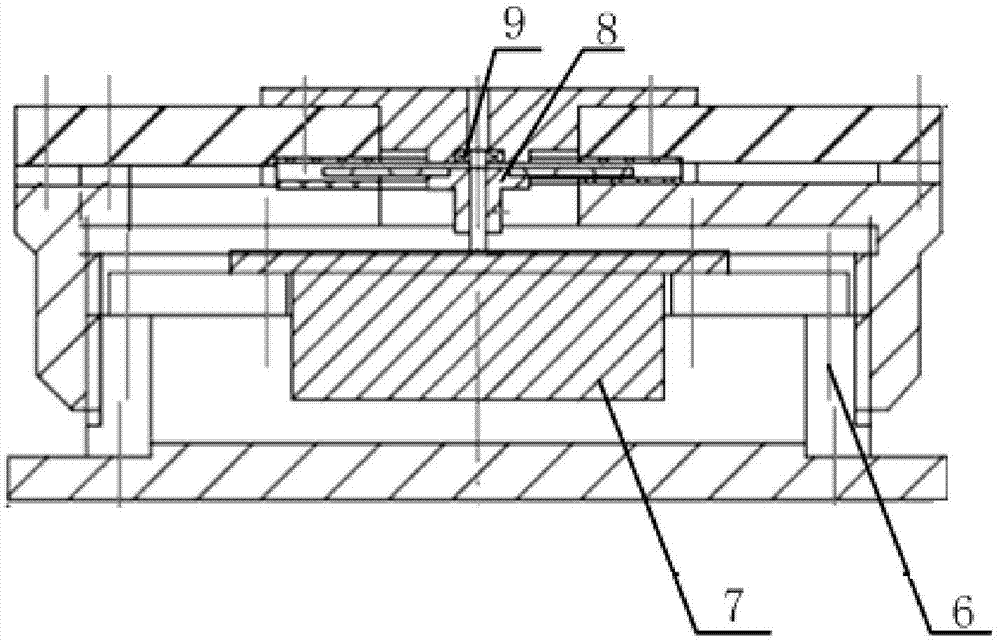

[0021] Such as figure 1 and 2 As shown, a fine-tuning gyroscope precision assembly structure with adjustable static capacitance includes a pulley base 1, a motor base 6, a lower electrode support 2, an upper electrode support 4, a rotor lower support piece 8, and a rotor upper pressure piece, Washer 3, bearing housing 5, bearing parts 9, motor 7, upper electrode, lower electrode, gyro rotor, nylon, pins, screws, etc. The pulley base 1 is assembled with the motor base 6, and the motor 7 is fixed on the motor base 6, and the pulley base 1 and the motor base 6 can rotate through the chute. The lower electrode is adhered to the lower electrode support 2, the motor base 6 and the lower electrode support 2 are threaded together, the distance between the lower electrode and the gyro rotor can be adjusted by rotation, and the lower electrode support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com