Micro capacitance-type wall shear stress sensor and manufacturing method thereof based on through silicon via (TSV) technology

A micro-capacitor and through-silicon via technology, applied in the field of sensors, can solve the problems of unfavorable sensor integration with IC process 3D packaging, easy introduction of interference in packaging methods, insufficient bonding strength, etc. The effect of reducing package size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

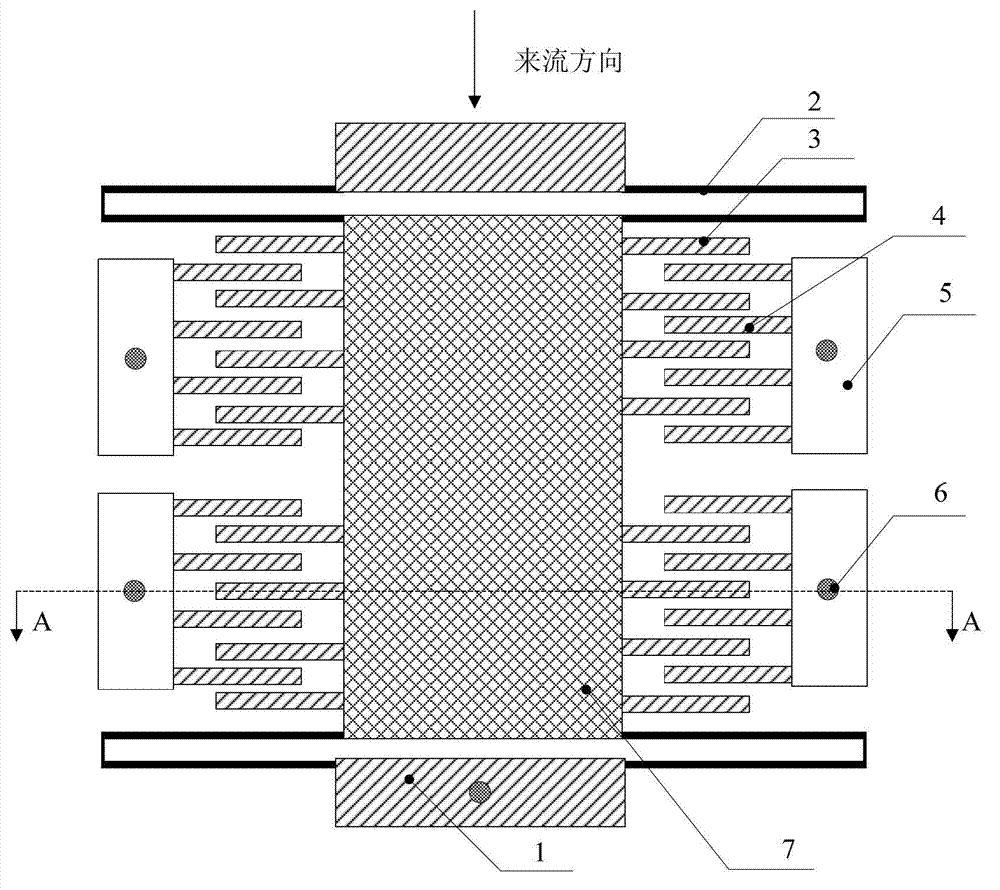

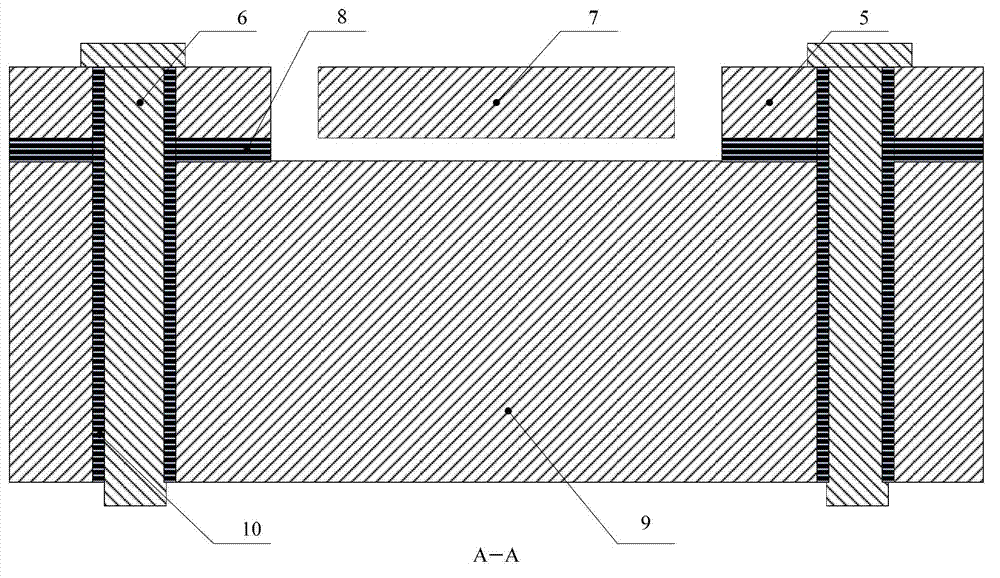

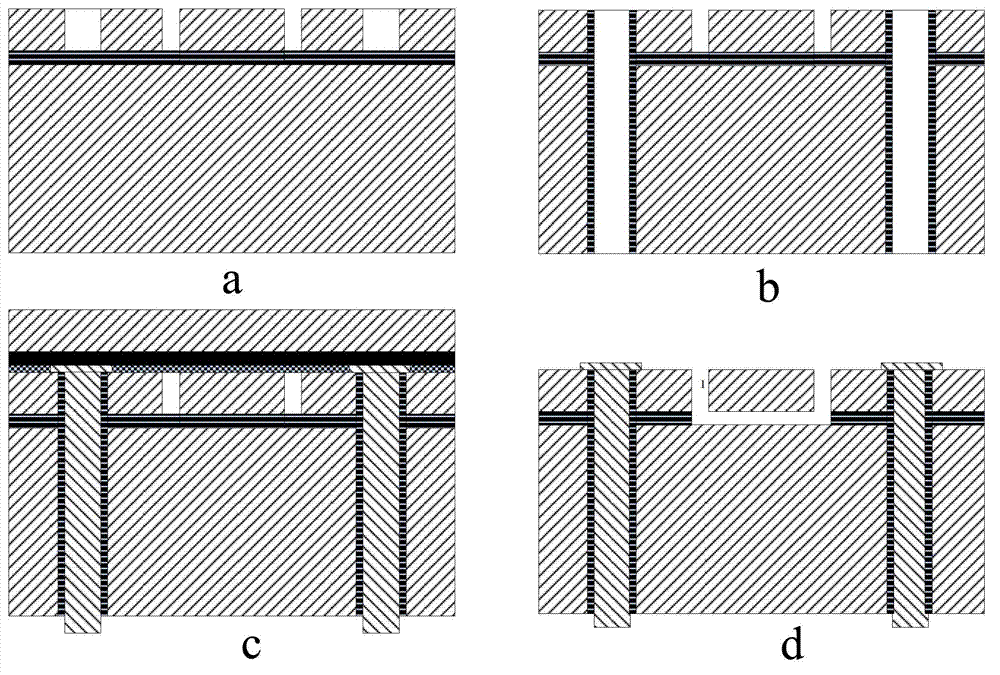

[0028] The miniature capacitive wall shear stress sensor based on the back hole connection of the through-silicon via technology in this embodiment mainly includes a floating unit anchor point 1, an elastic beam 2, a movable comb tooth 3, a fixed comb tooth 4, and a fixed comb tooth anchor point 5, TSV lead wire 6, floating unit 7, sacrificial layer 8, base layer 9 and TSV electrical insulation layer 10; the floating unit 7, elastic beam 2, movable comb 3, fixed comb 4 and anchor point are made The overall processing process is obtained, the electrical connection TSV is completed by electroplating, and the entire sensor is left-right symmetrical; the floating unit 7 and the movable comb 3 are connected to the anchor point 1 of the floating unit through the elastic beam 2, and are suspended on the base layer 9; the fixed comb 4 Connected to the fixed comb anchor point 5, the movable comb tooth 3 and the fixed comb tooth 4 form a capacitor, the TSV lead 6 forms electrical contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com