Rotating parts and components dynamic balance method based on strain

A technology of parts and balance force, which is applied in the field of dynamic balance of rotating parts based on strain, can solve problems affecting the performance of dynamic balancing machines, measurement accuracy limitations, etc., and achieve the effect of batch operation of dynamic balancing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

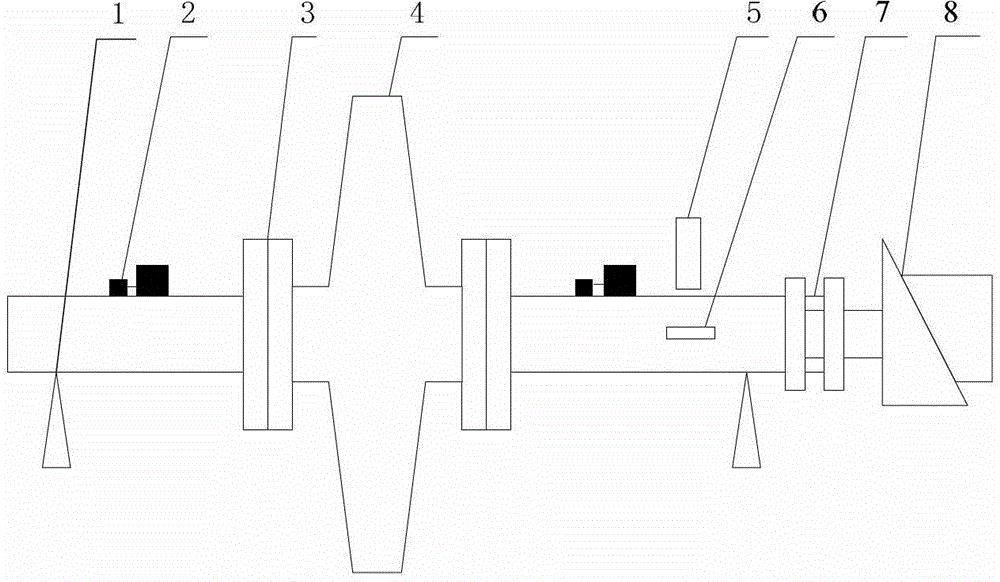

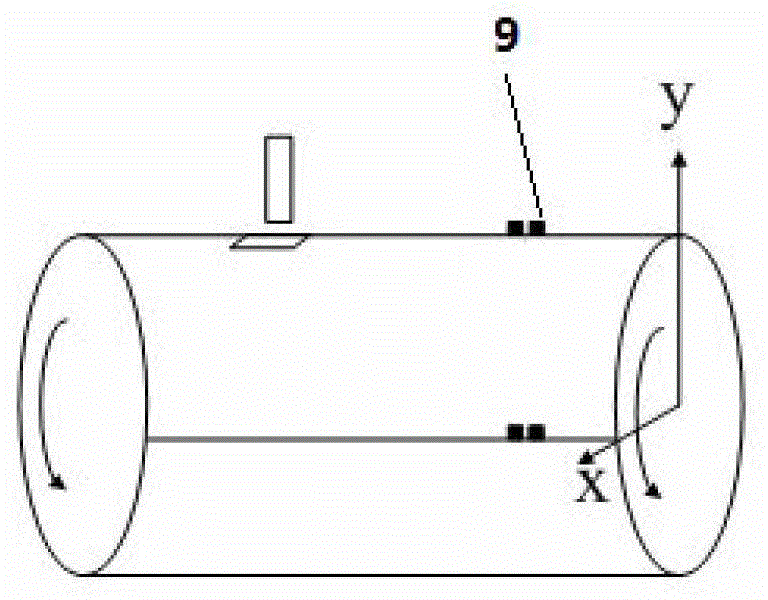

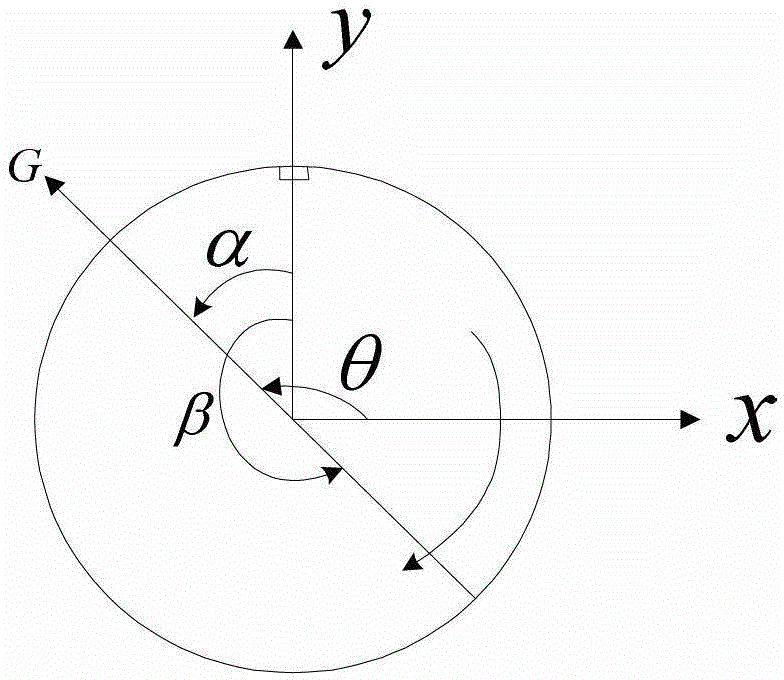

[0053] This embodiment is based on figure 1 The rotating parts test rig shown as an example is analyzed based on the strain-based rotor unbalance correction method. refer to Figure 2-7 .

[0054] The method for completing the unbalance correction of the rotating parts by measuring the strain involved in this embodiment is:

[0055] A. Install the rotating parts to be tested on the dynamic balance testing bench through the universal joint;

[0056] B. Install an eddy current sensor on the shaft section of the dynamic balance test bench, align the eddy current sensor with the keyway, and measure the pulse signal of the speed, which is used as a benchmark for multi-measuring point synchronous whole-cycle sampling analysis;

[0057] C. Select two measuring sections on the surface of the rotating shaft of the dynamic balance testing bench to install strain measuring points. Between the support bearings, two sets of strain gauges should be arranged on each section, one set of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com