Container sterilization method, and three-fluid nozzle used in sterilization method

A fluid nozzle and container technology, applied in the field of 3-fluid nozzles, can solve the problems of long sterilization time and larger scale of sterilization equipment, and achieve the effects of reducing operating costs, reducing installation places, and simplifying sterilization equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] In order to confirm the bactericidal effect of the present invention, the following experiments were carried out.

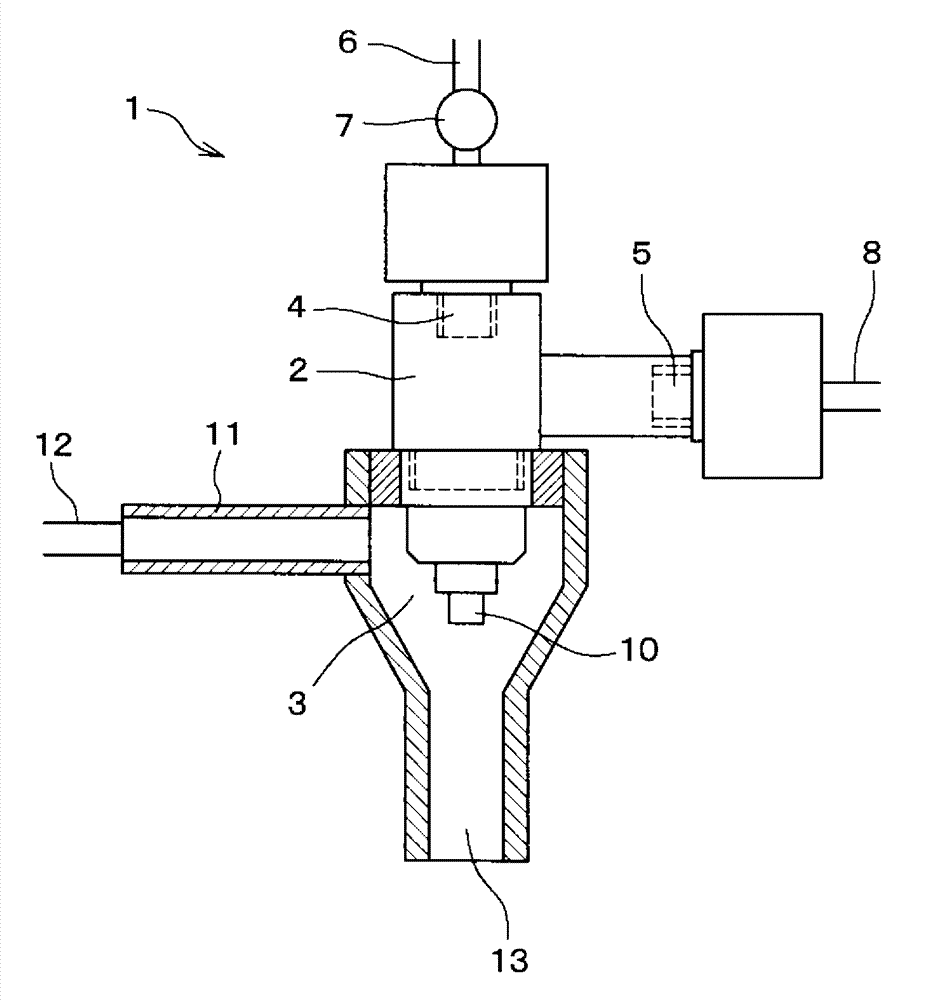

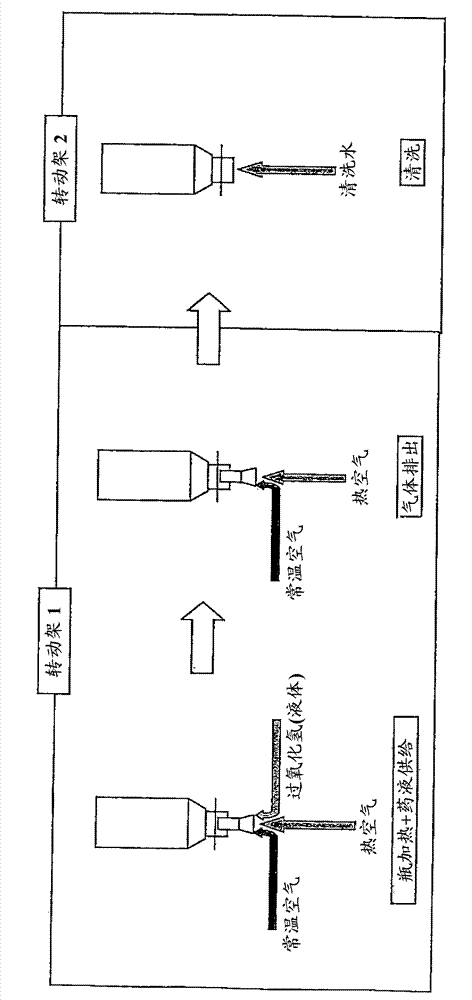

[0055] As a container to be sterilized in the experiment, a 500-ml PET bottle was used, and after the container was sterilized using the three-fluid nozzle described in FIG. 1 , the container was washed with warm water.

[0056] As sample bottles to be sterilized, ten 500-ml PET bottles were prepared. As the test bacteria, adjust the suspension of Bacillus subtilis var. niger NBRC13721 to the specified concentration, spray the inside of each sample bottle with 0.3ml of each bottle, and make the concentration reach 10 5 cfu / piece, make the bacterial suspension adhere to the inside of each bottle (initial bacterial count is 1.0×10 5 cfu / piece).

[0057] After the bacteria suspension was adhered, each bottle was stored in a clean room (class 10,000) for 24 hours to dry the inside of the bottle.

[0058] During sterilization, 30% hydrogen peroxide aqueous s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com