Biomass tooth mould pellet press

A granulator and biomass technology, applied in the field of machinery, can solve the problems of compressed granules such as long heat dissipation time, excessive gaps, and insufficient pressure, and achieve the effects of increasing farmers' income, ensuring stability, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

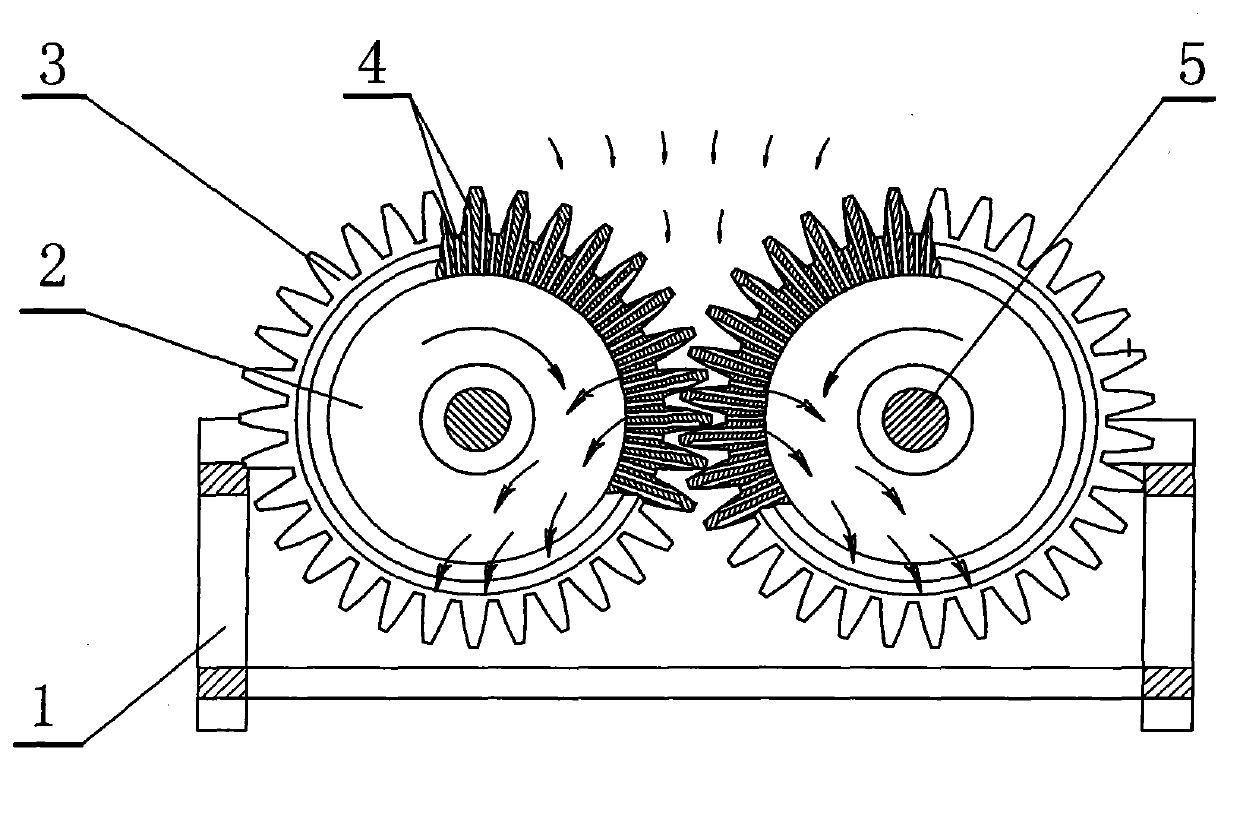

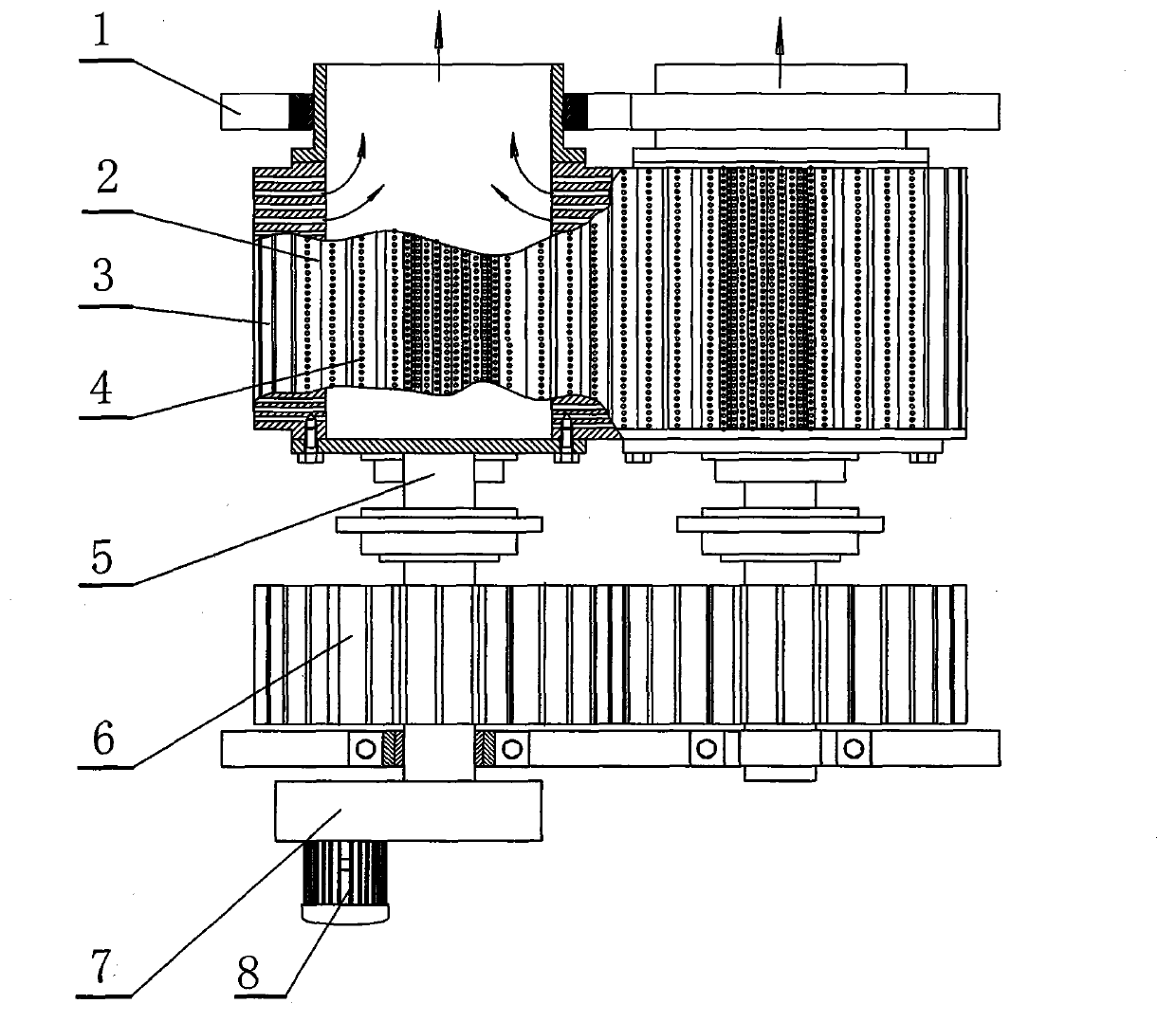

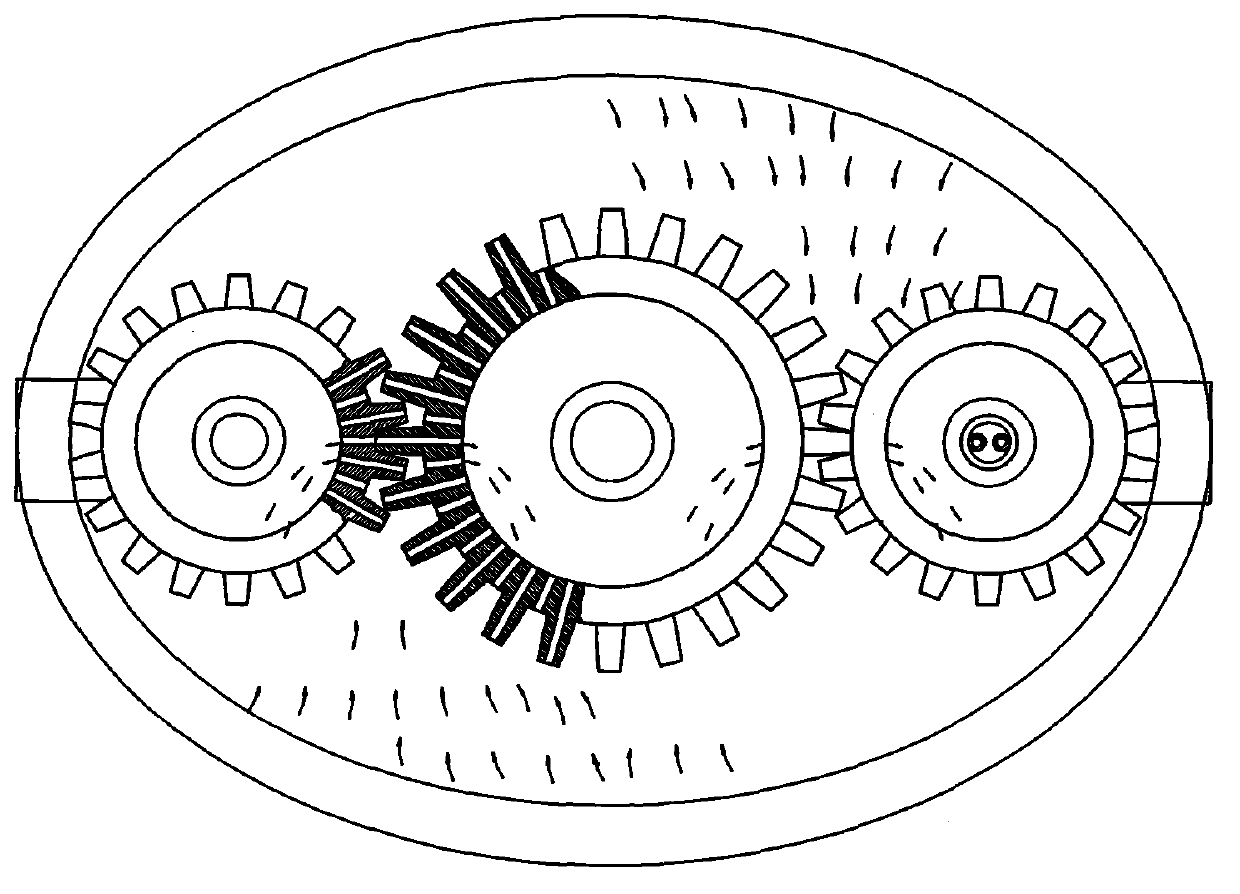

[0028] The first embodiment: as figure 1 , 2 As shown, a pair of extruding gears 2 meshing with each other is installed on the frame 1 of this biomass tooth mold pelletizer. The extruding gears 2 are in the shape of a cylinder. A plurality of through holes 4 . The improvement is that a pair of intermeshing decompression gears 6 are installed on the two gear shafts 5 of the two extruding gears 2. The decompression gears 6 do not carry out particle extrusion operations, and their functions mainly include two points: one is Determine the installation positions of the two extrusion gears 2, that is, limit the gap between the two extrusion gears 2, so as to ensure that the two extrusion gears 2 can work under the optimal gap. The second is to withstand pressure. The extrusion gear 2 is greatly reduced in strength due to having a plurality of through holes 4, and it is easy to be damaged when extruding each other. With the decompression gear 6, it can withstand most of the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com