Design method for optimal damping ratio of suspension system of cab

A technology of optimal damping ratio and optimal damping ratio, applied in the superstructure, superstructure, transportation and packaging of trucks, etc., can solve the problems such as the design requirements that cannot meet the comfort of the vehicle cab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

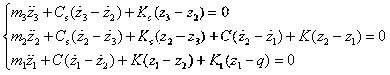

Embodiment 1

[0049] Example 1: Mounting of a truck cab, where one-side mounting corresponds to the quality of the cab kg, the cab mount elastic coefficient corresponding to one side mount N / m; car body mass corresponding to a single wheel kg, the sprung mass, the suspension spring stiffness N / m, suspension damping coefficient N.s / m; unsprung mass kg, tire stiffness N / m; Class C pavement reference spatial frequency m -1 The pavement power spectral density value under m 3 , the vehicle speed km / h; vertical displacement coordinates of wheels, body and cab , and ;Input road roughness function .

[0050] The optimal damping ratio design process of the cab mount provided by the present invention is as follows: figure 2 As shown, the specific steps are as follows:

[0051] (1) Determine the vertical vibration acceleration frequency response function of the cab and wheel dynamic load frequency response function :

[0052] According to the cab quality corresponding ...

Embodiment 2

[0083] Embodiment two : One-side suspension mass of a truck cab kg, elastic coefficient of one side suspension N / m; Other parameters are identical with embodiment one. Adopt the design steps of embodiment one, namely:

[0084] (1) Determine the vertical vibration acceleration frequency response function of the cab and wheel dynamic load frequency response function :

[0085] According to the quality of one side suspension of a truck cab kg, the elastic coefficient of one-side suspension of the cab N / m; car body mass corresponding to a single wheel kg, the sprung mass, the suspension spring stiffness N / m, suspension damping coefficient N.s / m; unsprung mass kg, tire stiffness N / m; vertical displacement coordinates of wheels, body and cab , and ;Input road roughness function ;According to the vehicle parameters and the driving vibration differential equation, determine the frequency response function of the vertical vibration acceleration of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com