Method for preparing 4A zeolite by using fluorine-containing white residues through single-step crystallization

A technology of fluorine-containing silicon slag and crystallization, which is applied to the removal of crystalline aluminosilicate zeolite, A-type crystalline aluminosilicate zeolite, solid waste, etc., can solve the problem of less comprehensive utilization of fluorine-containing silicon slag, and achieve a large The effect of social environmental economic benefits, reduction of production costs, and saving of grinding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

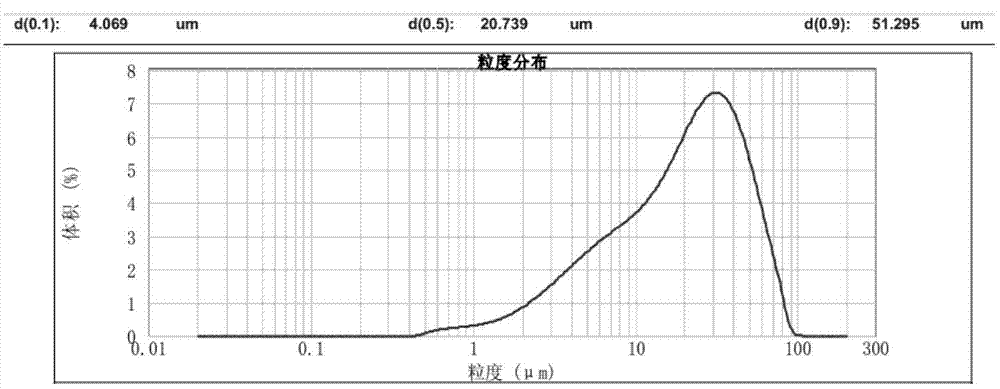

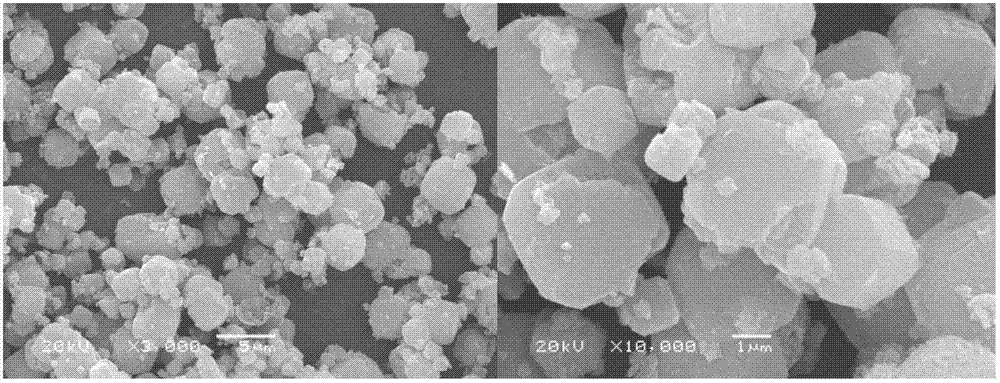

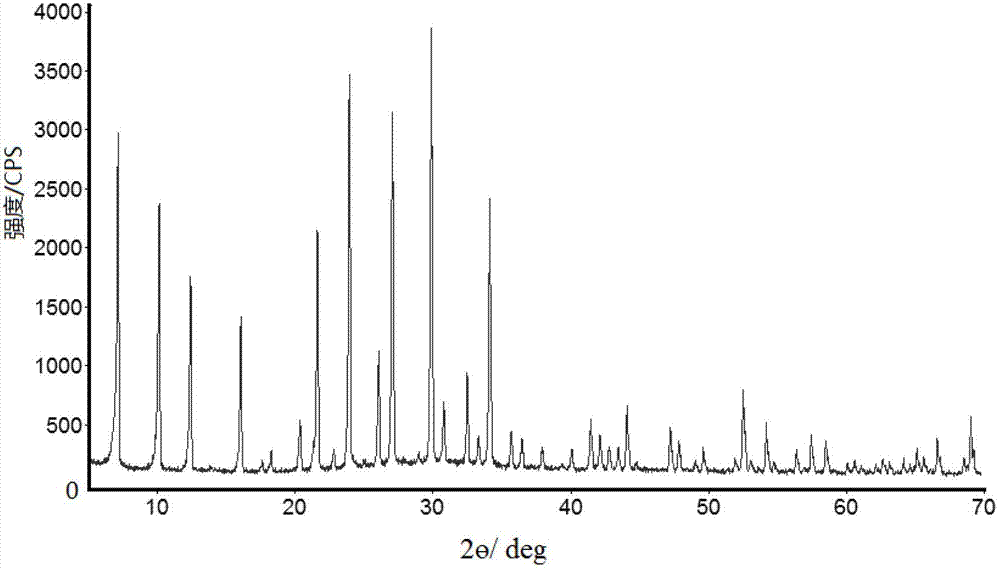

[0036] Embodiment 1: take by weighing 50g fluorine-containing silicon slag, calculate silicon, aluminum molar weight wherein, according to the ratio n(SiO 2 ): n(Al 2 o 3 )=1.8:1, n(Na 2 O): n(SiO 2 )=1.2:1, n(H 2 O): n(Na 2 O)=35, weigh Al(OH) 3 Put NaOH in a beaker, add deionized water, control the temperature and stir to make it fully react to form a sodium metaaluminate solution; then weigh NaOH, add deionized water to prepare a solution. Put fluorosilicon slag, sodium metaaluminate and NaOH solution into a reaction kettle with a stirring device, stir well to make the mixture uniform, and add a zeolite crystallization directing agent accounting for 1.5% of the volume ratio of the reaction system at the same time. The directing agent is the raw material material The ratio of the amount of 3Na 2 O·Al 2 o 3 2SiO2 2 ·85H 2 O's sol system. The reaction kettle was placed in an electrothermal constant temperature device, the stirring speed was controlled at 240r / min, ...

Embodiment 2

[0040] Embodiment 2: take by weighing 100g fluorine-containing silicon slag, calculate silicon, aluminum molar weight wherein, according to the ratio n(SiO 2 ): n(Al 2 o 3 )=1.9:1, n(Na 2 O): n(SiO 2 )=1.0: 1, n(H 2 O): n(Na 2 O)=40:1, weigh sodium metaaluminate in a beaker, and add deionized water to make sodium metaaluminate solution; then weigh NaOH, add deionized water to prepare a solution. Put fluorosilicon slag, sodium metaaluminate solution and NaOH solution into a reaction kettle with a stirring device, stir well to make the mixture uniform, and add a zeolite crystallization directing agent accounting for 1.0% of the volume ratio of the reaction system at the same time (same as Example 1) , put the reaction kettle in an electric heating constant temperature device, stir while maintaining a constant temperature, and react under the conditions of a crystallization temperature of 85°C, a crystallization time of 3h, and a stirring speed of 250r / min. After the crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com