Evaporative-type condenser and heat source device of the same

An evaporative condenser and heat source technology, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of insufficient heat exchange area, inability to realize cold and heat conversion, and difficulty in continuous oil return, and reduce production. Cost, beneficial to cost control, the effect of reducing the external size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiment of the present invention and its changed examples are described in detail below in conjunction with the accompanying drawings by way of illustration rather than limitation of the scope of protection required by the inventive idea.

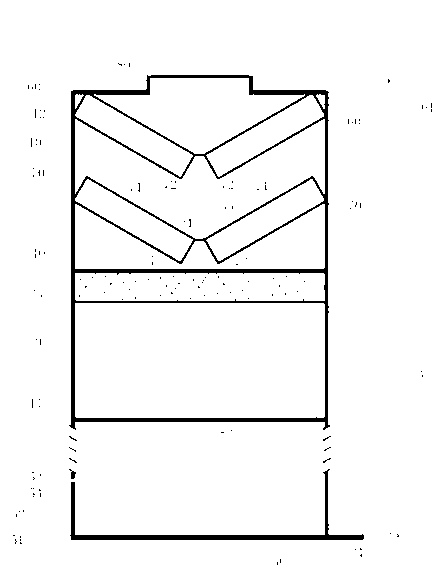

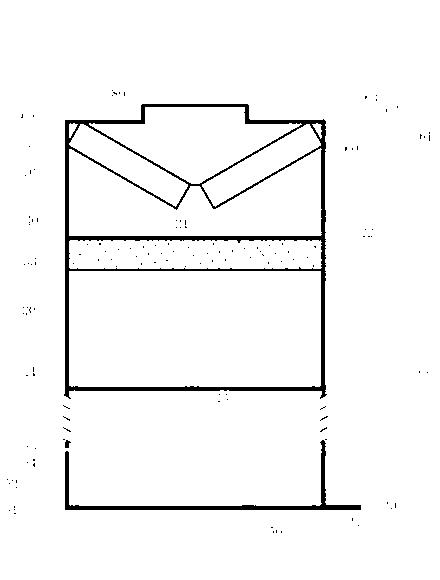

[0024] figure 1 It is a schematic diagram of the main structure and working principle of the evaporative condenser and its heat source device as the first specific embodiment of the present invention. The evaporative condenser and its heat source device of the present invention mainly include a box body 10 divided into upper and lower sections, which are connected together by a frame 12 to form a whole, and the first heat exchanger 20 is arranged at the lower section of the box body 10 The upper part, the bottom of the lower section of the box body 10 is a water collection tank 50, and an inlet grille 11 is provided between the water collection box 50 and the first heat exchanger 20, and the inside of the upper secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com