Defrosting device for closed type heat source tower

A heat source tower, closed technology, applied in the field of defrosting devices, can solve the problems of untreated discharge of antifreeze, high operating costs, blockage, etc., and achieve the effect of reducing heat energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

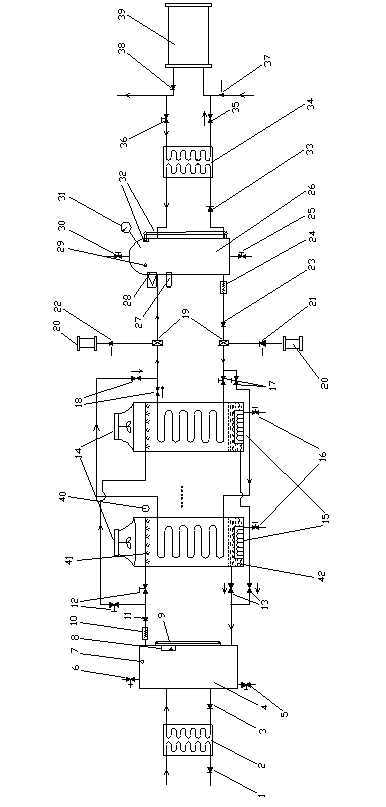

[0024] Such as figure 1 As shown, a defrosting device for a closed heat source tower includes an external defrosting system that sprays solution to the outer wall and fins of the heat source tower heat exchange coil and injects high-temperature antifreeze into the heat exchange coil in the heat source tower 14 The internal defrosting system; the external defrosting system includes a solution pool 4, an external defrosting heating mechanism 2 for heating the solution in the solution pool 4, and the liquid outlet of the solution pool 4 is connected to a heat source provided by a pipeline The nozzle 41 above the tower, the connection of the liquid storage tank 42 at the bottom of the heat source tower and the liquid inlet of the solution pool 4; The internal defrosting heating mechanism 34, the liquid outlet of the liquid storage tank 26 is connected to one end of the heat exchange coil through a pipeline, and the liquid inlet of the liquid storage tank 26 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com