Open-type roasting furnace heating curve and furnace moving operational method

A technology for moving furnace operation and roasting furnace, which is applied in the field of open roasting furnace heating and moving furnace operation, which can solve the problems of increased air leakage, incomplete combustion of tar, increased air leakage in preheating furnace chamber, etc. The pressure, solve the accumulation of tar, improve the effect of the flue temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

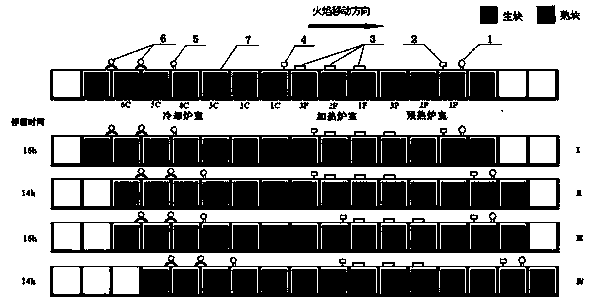

[0019] As shown in the figure, the open-type roasting furnace heating method and the furnace moving operation method of the present invention, after the six chambers of the heating zone of the system have been operating normally for a period of time, the combustion frame 3 of the third heating furnace chamber is moved to the third preheating furnace chamber in advance 3P performs forced heating, and the zero-pressure frame moves from the first cooling furnace room to the third heating furnace room, and the heating zone enters the five-room operation. After heating to the normal furnace moving time, other furnace surface equipment is moved and heated The zone re-enters the sixth room to operate normally, and the furnace is moved at the same time as the combustion rack and other furnace surface equipment, so as to realize the alternate operation of the sixth room and the fifth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com