Ultrasound magnetic force composite efficient finishing process device

A technology of finishing processing and magnetic force, which is applied in the field of ultrasonic magnetic combined high-efficiency finishing processing devices, can solve the problems of small application range, low processing efficiency, and difficult collection of abrasives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

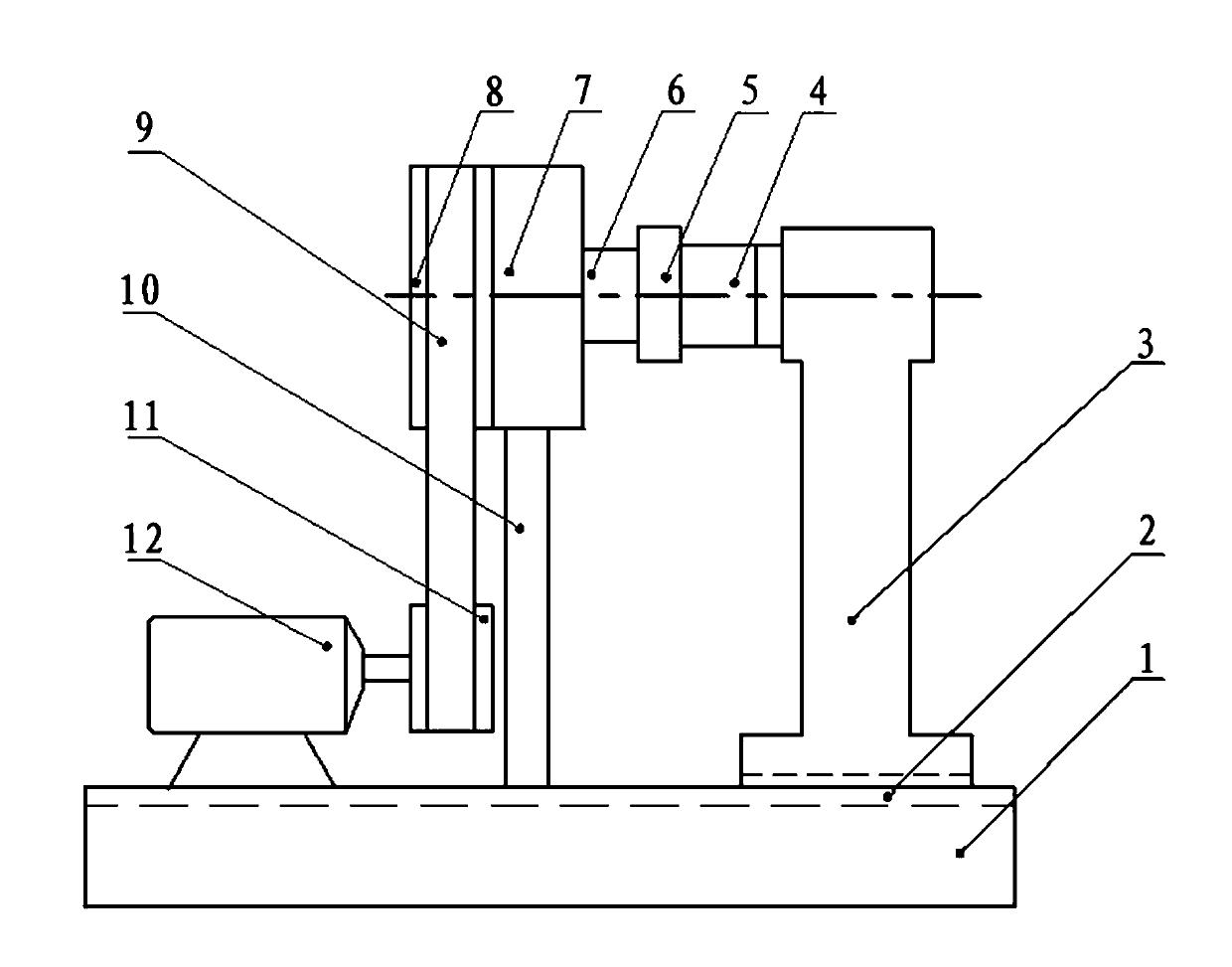

[0018] Ultrasonic magnetic composite high-efficiency finishing device, including workbench 1, guide rail 2, tailstock 3, giant magnetostrictive transducer 4, fixture 5, cylindrical workpiece 6, magnetic field generating device 7, large pulley 8, V Belt 9, fixed support 10, small pulley 11, and motor 12;

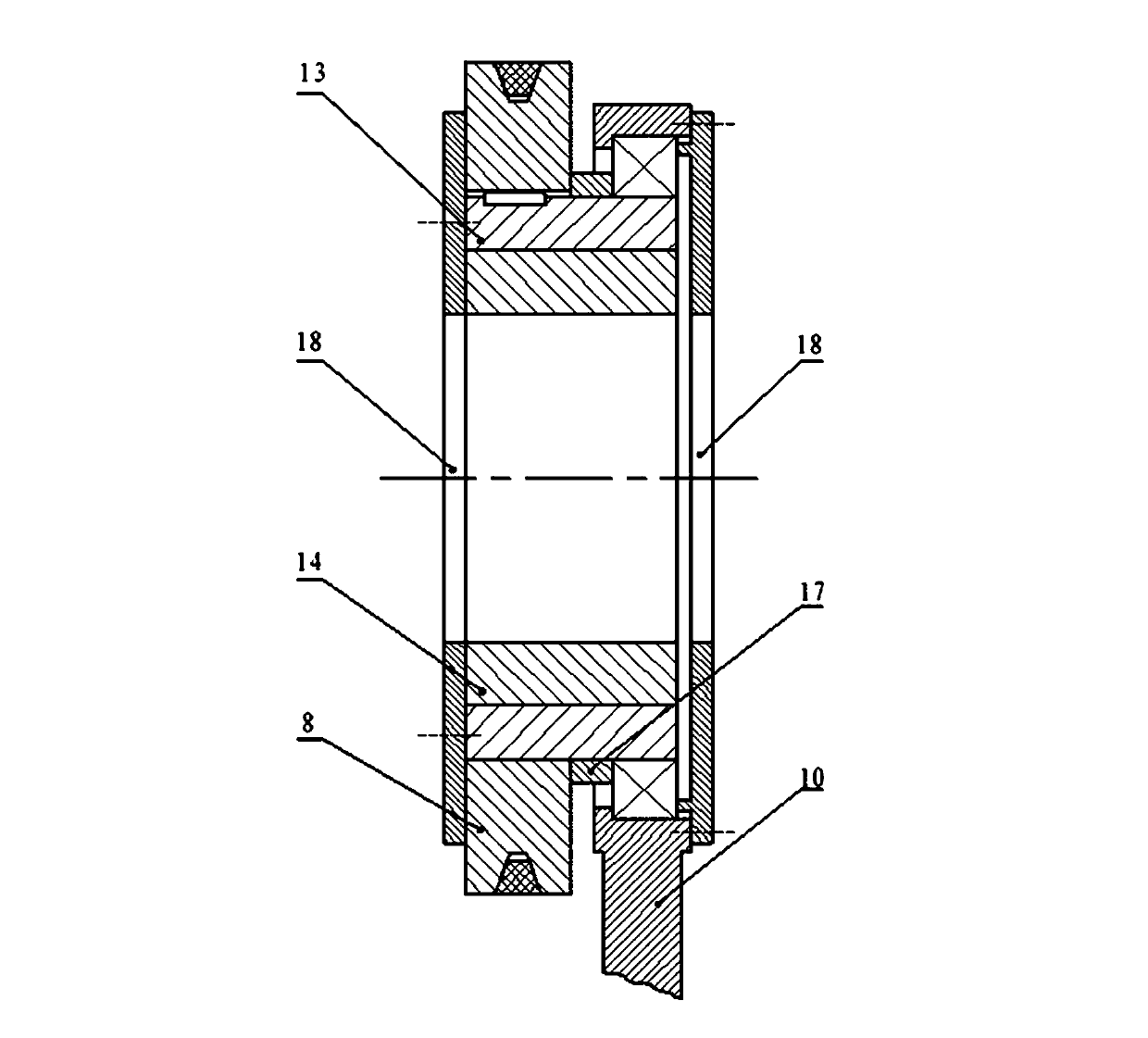

[0019] The magnetic field generating device 7 includes an annular yoke 13, a tile-shaped permanent magnet pole 14, a magnetic grinding tool 15, a sleeve 17, and an end cap 18;

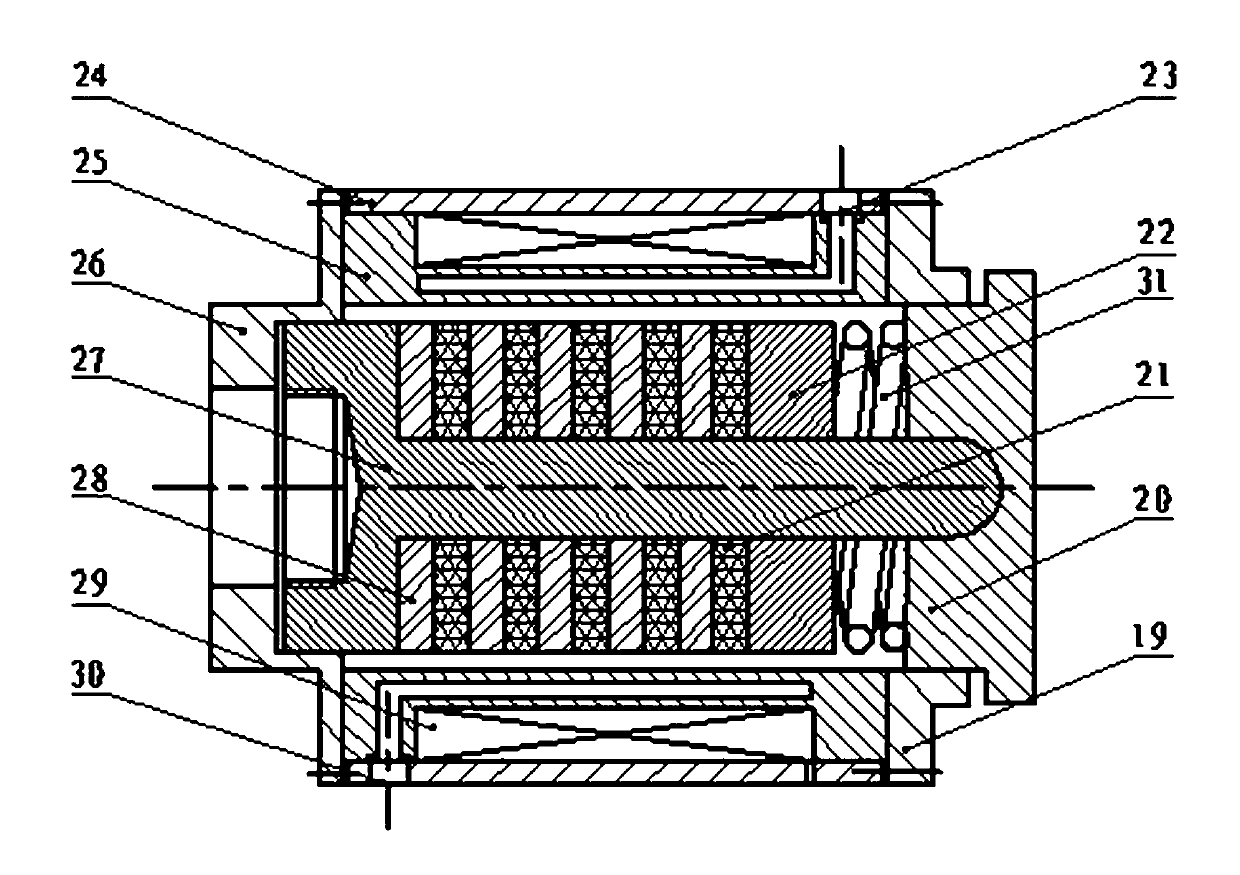

[0020] The giant magnetostrictive transducer 4 includes a rear end cover 19, a pre-tightening nut 20, a briquetting block 22, a cooling water inlet 23, a cylindrical shell 24, a cylindrical coil former 25, a front end cover 26, and a pressing rod 27 , excitation coil 29, cooling water outlet 30, preload spring 31, and cylindrical rare earth giant magnetostrictive rod;

[0021] The guide rail 2 is installed on the upper surface of the workbench 1; the base of the motor 12, the lower end of the fixed b...

Embodiment 2

[0028] Ultrasonic magnetic composite high-efficiency finishing device, including workbench 1, guide rail 2, tailstock 3, giant magnetostrictive transducer 4, fixture 5, cylindrical workpiece 6, magnetic field generating device 7, large pulley 8, V Belt 9, fixed support 10, small pulley 11, and motor 12;

[0029] The magnetic field generating device 7 includes an annular yoke 13, a tile-shaped permanent magnet pole 14, a magnetic grinding tool 15, a sleeve 17, and an end cap 18;

[0030] The giant magnetostrictive transducer 4 includes a rear end cover 19, a pre-tightening nut 20, a briquetting block 22, a cooling water inlet 23, a cylindrical shell 24, a cylindrical coil former 25, a front end cover 26, and a pressing rod 27 , excitation coil 29, cooling water outlet 30, preload spring 31, and cylindrical rare earth giant magnetostrictive rod;

[0031] The guide rail 2 is installed on the upper surface of the workbench 1; the base of the motor 12, the lower end of the fixed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com