Catenary dropper numerical control preplan platform

A catenary and platform technology, applied in overhead lines and other directions, can solve the problems of low automation and pre-assignment accuracy, and achieve the effect of ensuring construction quality, accuracy and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

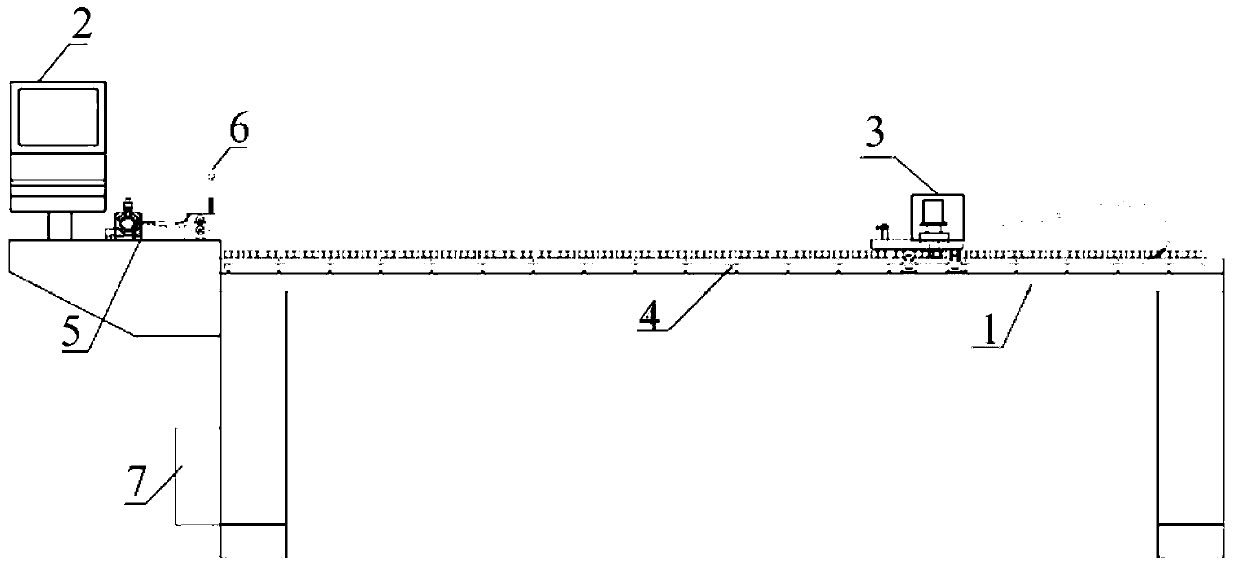

[0022] Such as figure 1 The schematic catenary hanging string numerical control pre-configuration platform includes a main body 1, a computer 2, a length positioning device 3, a linear guide rail 4, a crimping device 5, a tensioning device 6, and a control box 7. It is characterized in that: the main body 1 A linear guide rail 4 is fixed, a length positioning device 3 is installed on the linear guide rail 4 , a crimping device 5 and a tensioning device 6 are welded on the left end of the main body 1 .

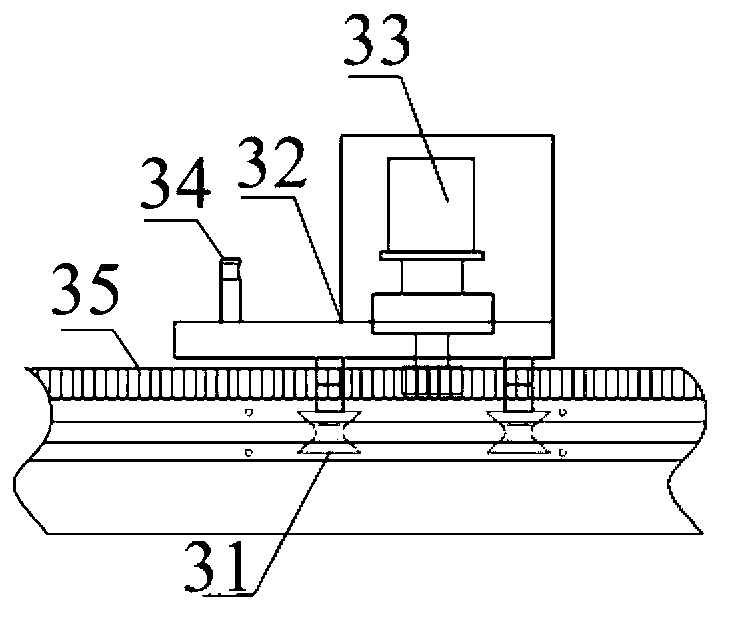

[0023] Such as figure 2 As shown, the length positioning device 3 is composed of a bearing slider 31, a motor bracket 32, a stepping motor 33, a heart-shaped ring fixing column 34, and a rack 35. The bearing slider 31 is divided into two groups, and the front and rear ferrules are set on the linear guide rail. 4, the motor bracket 32 is fixed on the bearing slider 31 by bolts, the stepper motor 33 is fixed on the motor bracket 32 by bolts, the heart-shaped ring fixing col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com