Wire drawing head of filler cap and automobile

A fuel filler cap and thread head technology, which is applied to vehicle components, superstructure, and subassembly of the superstructure, etc., can solve the problems of difficult installation, affecting production rhythm, and prone to potential safety hazards, so as to avoid potential safety hazards and improve visibility. The effect of avoiding hand cuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

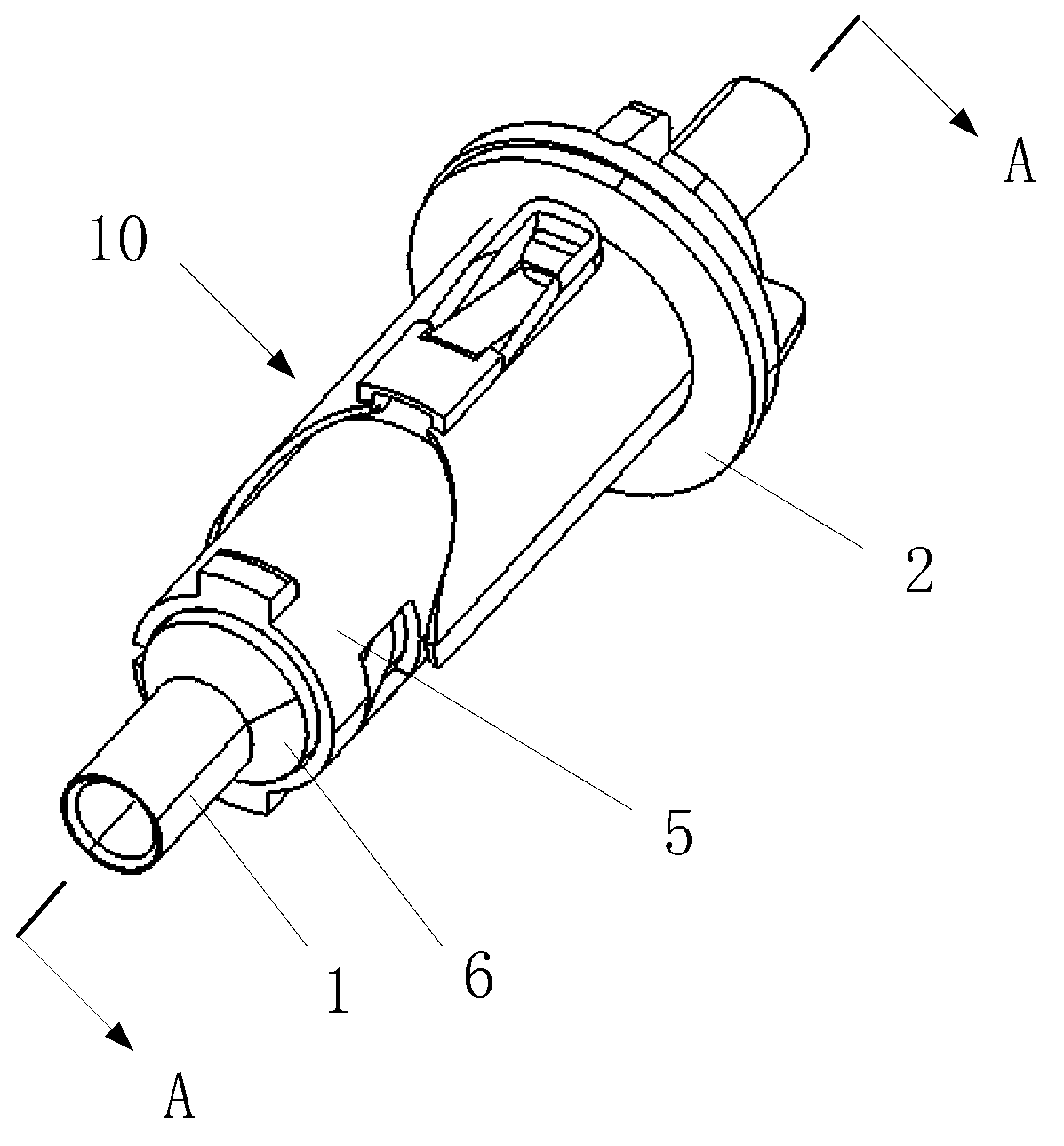

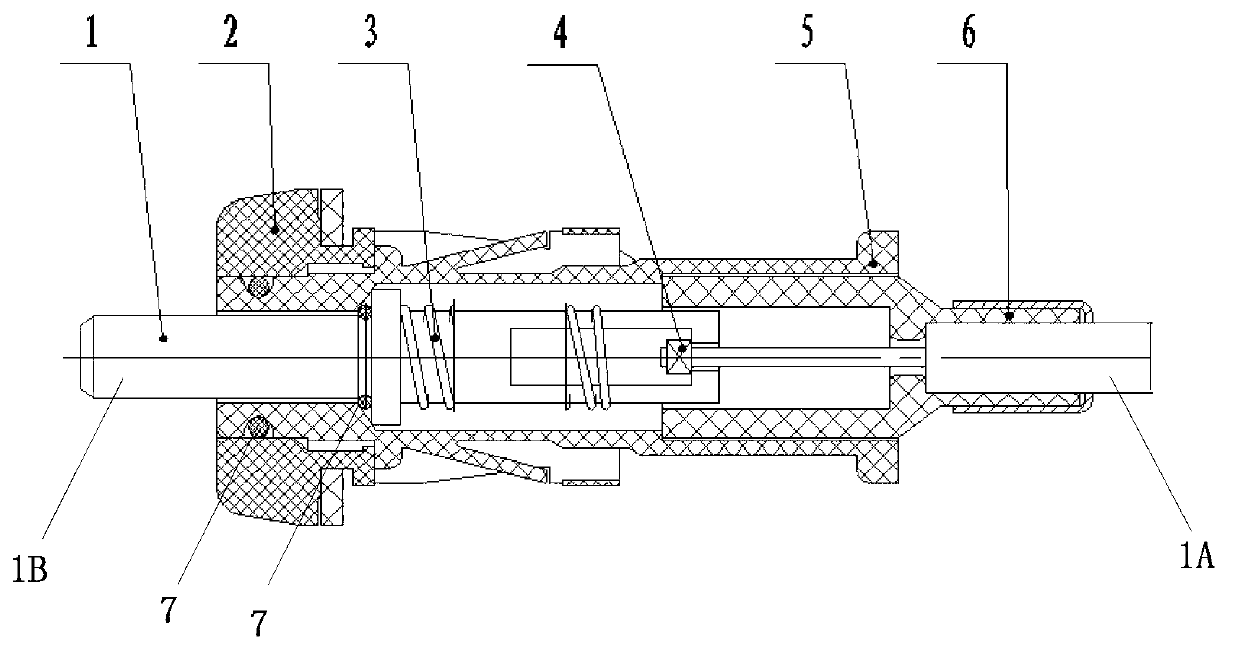

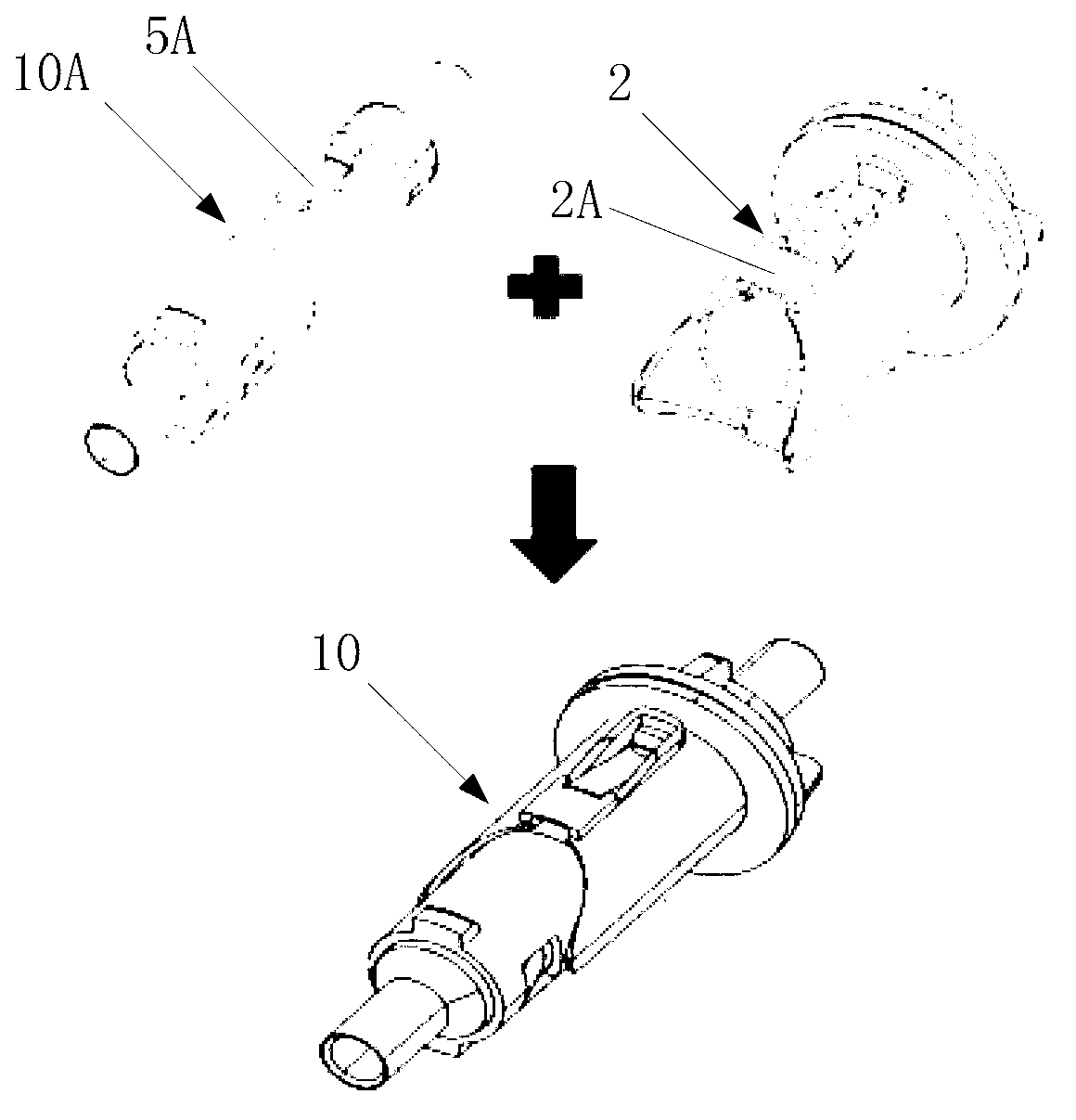

[0032] Such as figure 1 shown, see also figure 2 and image 3 , the embodiment of the present invention takes figure 1 To illustrate the main purpose, the present invention provides a fuel filler cap puller 10, which includes: a pillar 1, a rivet 4 (see figure 2 ), tower 6, compression spring 3 (see figure 2 ), tower cover 5 and sheath 2, the rivets 4 (see figure 2 ) from one end of the strut 1A (see figure 2 ) into and riveted, the rivets 4 (see figure 2 ) is used to drive the pillar 1 to do linear motion, and the rivet 4 (see figure 2 ) and the strut end 1A (see figure 2 ) is sleeved on the outside of the tower 6, the tower 6 is used to support the tower cover 5, the tower 6 is used to limit the movement position of the pillar 1, the pillar 1 and the tower 6 is provided with said compression spring 3 (see figure 2 ), the compression spring 3 (see figure 2 ) is used to reset the pillar 1, the tower base 6 and the other end 1B of the pillar (see figure 2 ...

Embodiment 2

[0044] Such as Figure 4 As shown, the present invention also provides a kind of automobile, and described automobile comprises fuel filler box 20, also comprises described fuel filler cap pull wire 10, and described fuel filler cap pull wire 10 is installed on the described fuel filler by exterior Box 20 on. Wherein, the specific structure of the fuel filler cap pull wire 10 is exactly the same as that of the fuel filler cap pull wire 10 in the first embodiment, and the specific structure of the fuel filler cap pull wire 10 will not be repeated in this embodiment.

[0045] see Figure 4 , because the fuel filler cap puller 10 can be installed in the car as an exterior, it effectively improves the visibility during installation, makes the installation easy, improves the production cycle, and can effectively avoid cuts on the hands of the installers. and other safety hazards, and then make the automobile with the fuel filler cap pull wire 10, the on-site assembly efficiency i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com