Preparation method of low polished cerium oxide polishing powder

A technology of cerium oxide and polishing powder, applied in chemical instruments and methods, inorganic chemistry, other chemical processes, etc., can solve the problems of high finish and stable aperture of optical components at the same time, and achieve low production cost and high finish aperture , The effect of the simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

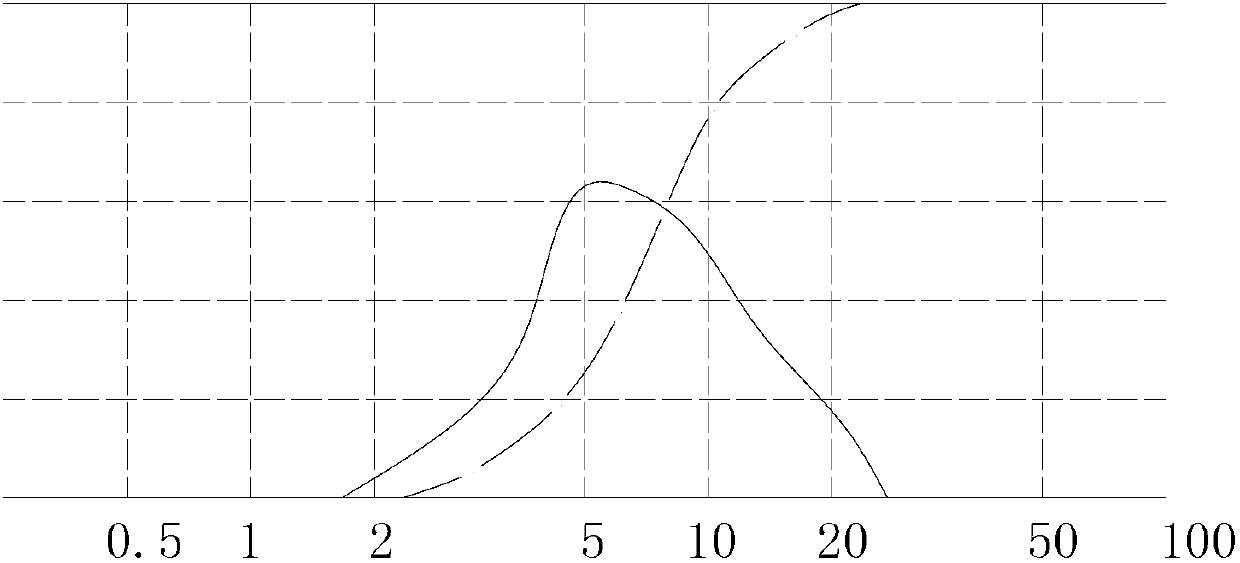

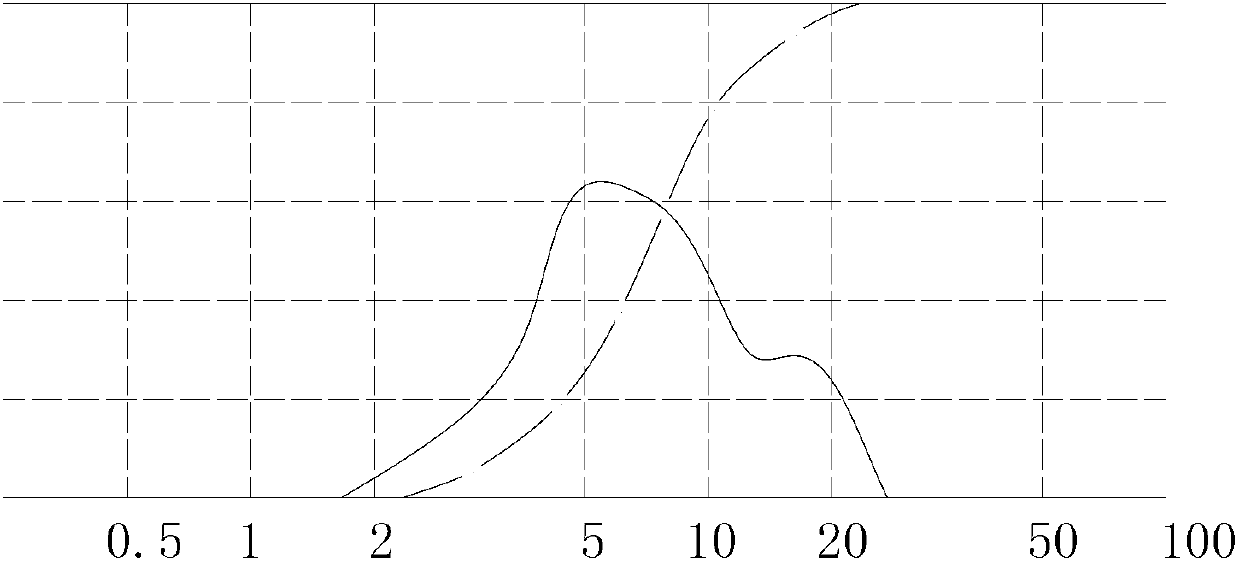

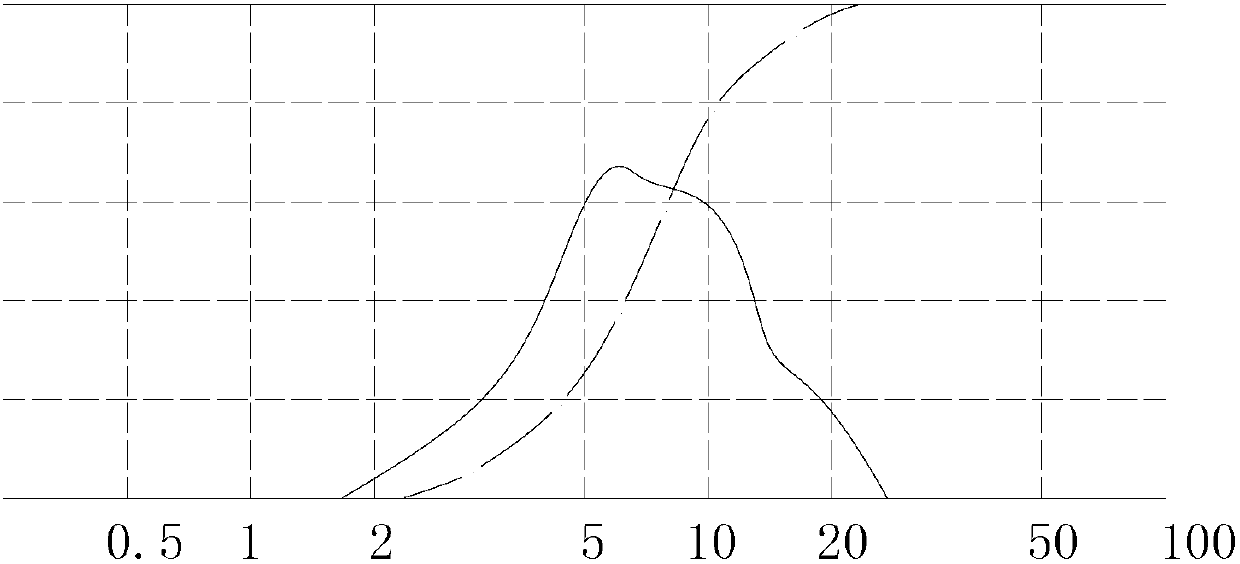

Image

Examples

Embodiment 1

[0029] A preparation method of low throw cerium oxide polishing powder, the concrete steps are as follows:

[0030] (1) First add 6.4L of 3N5 cerium nitrate solution with a concentration of 230g / L into a 25L reaction kettle, start stirring, and control the speed at 100-150R / min;

[0031] (2) Put 44 grams of cerium oxalate material into the reactor, start to heat up the material in the reactor, and keep the temperature of the material at 45-60°C;

[0032] (3) Add oxalic acid solution with a concentration of 250g / L to the material in step (2) dropwise at a constant speed at 45-60°C. The amount of oxalic acid solution added accounts for 110% of the total rare earth REO, and the time for adding oxalic acid solution is controlled at 30-45 Within minutes, continue to stir for 20-45 minutes after the oxalic acid solution is added dropwise to obtain the required cerium oxalate precipitate;

[0033] (4) After stopping the stirring, let the cerium oxalate precursor precipitate and stan...

Embodiment 2

[0037] A preparation method of low throw cerium oxide polishing powder, the concrete steps are as follows:

[0038] (1) Add 6.4L of 3N5 cerium nitrate solution with a concentration of 150g / L into a 25L reactor, start stirring, and control the speed at 100-150R / min;

[0039] (2) Put 30 grams of cerium oxalate material into the reactor, start to heat up the material in the reactor, and keep the temperature of the material at 50-60°C;

[0040] (3) Add oxalic acid solution with a concentration of 250g / L to the material in step (2) at a constant speed at 50-60°C. The amount of oxalic acid solution added accounts for 110% of the total rare earth REO, and the time for adding oxalic acid solution is controlled at 35-45 Within minutes, continue to stir for 25-40 minutes after the oxalic acid solution is added dropwise to obtain the required cerium oxalate precipitate;

[0041] (4) After stopping the stirring, let the cerium oxalate precursor precipitate and stand for 20-30 minutes, th...

Embodiment 3

[0045] A preparation method of low throw cerium oxide polishing powder, the concrete steps are as follows:

[0046] (1) Add 6.4L of 3N5 cerium nitrate solution with a concentration of 150g / L into a 25L reactor, start stirring, and control the speed at 100-150R / min;

[0047] (2) Put 38 grams of cerium oxalate material into the reactor, start to heat up the material in the reactor, and keep the temperature of the material at 50-60°C;

[0048] (3) Add oxalic acid solution with a concentration of 165g / L to the material in step (2) dropwise at a constant speed at 50-60°C. The amount of oxalic acid solution added accounts for 110% of the total rare earth REO, and the time for adding oxalic acid solution is controlled at 35-40 Within minutes, continue to stir for 25-35 minutes after the oxalic acid solution is added dropwise to obtain the desired cerium oxalate precipitate;

[0049] (4) After stopping the stirring, first precipitate the cerium oxalate precursor and continue to stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com