Biological filter culture method and water treatment method for underground water

A technology of biological filter and cultivation method, applied in biological water/sewage treatment, polluted groundwater/leachate treatment, sustainable biological treatment, etc., can solve the problems of long start-up period and unstable effluent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

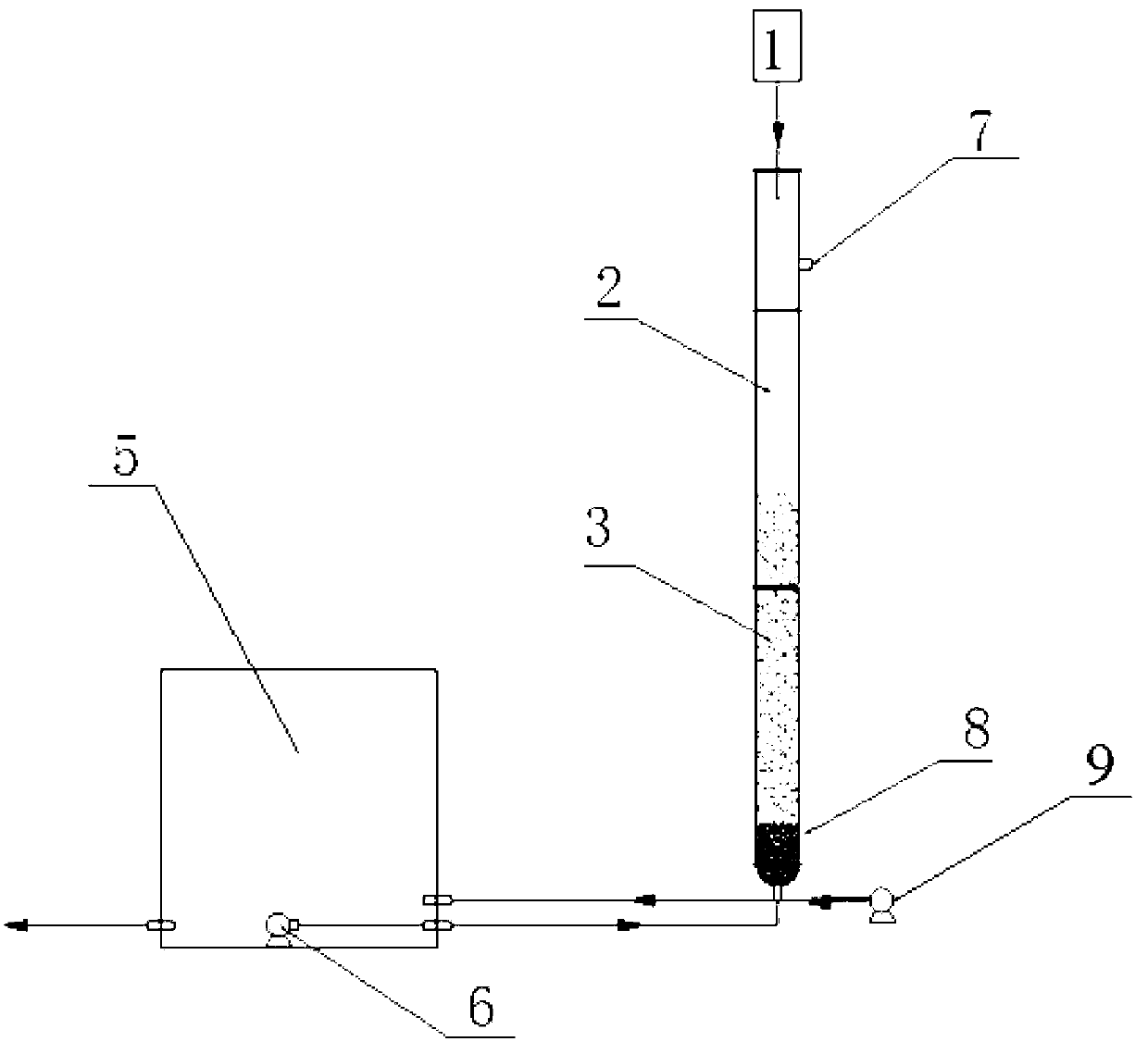

[0013] Specific embodiment one: the cultivation method of the biofilter of the present embodiment is carried out according to the following steps:

[0014] 1. Take the backwash water in stable operation, and then add (NH 4 ) 2 CO 3 、KH 2 PO 4 , NaCl, MgSO 4 and NaNO 3 , where backwash water and (NH 4 ) 2 CO 3 The ratio of 6L: 47g, backwash water and KH 2 PO 4 The ratio of 6L: 57g, backwash water and MgSO 4 The ratio of backwash water to NaCl is 3L: 25g, the ratio of backwash water to NaCl is 6L: 75g, backwash water to NaNO 3 The ratio of 3L: 5g, then add FeSO 4 ·7H 2 O, MnSO 4 ·H 2 O, NaAsO 2 and NaH 2 AsO 4 , to get a mixed solution, Fe in the mixed solution 2+ The concentration is 3mg / L, Mn 2+ The concentration of As is 1mg / L, and the concentration of As is 100μg / L;

[0015] 2. Pass the mixed solution prepared in step 1 into the biofilter 2, and open the micro-aeration system 9 at the same time to make the dissolved oxygen in the biofilter 2 be 7mg / L, cu...

specific Embodiment approach 2

[0016] Embodiment 2: This embodiment differs from Embodiment 1 in that the cultivation time in step 2 is 35 days. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Specific embodiment three: the water treatment method of groundwater in this embodiment is carried out according to the following steps:

[0018] 1. Close the bottom micro-aeration system 9, pass the raw water through the drop water aeration system 1, until the dissolved oxygen in the drop water aeration system 1 is 6-8 mg / L, and the water is discharged;

[0019] Two, pass the effluent of step 1 into the biofilter 2 cultivated by specific embodiment 1, run to the concentration of iron in the effluent less than 0.3mg / L, the concentration of manganese less than 0.1mg / L, the concentration of arsenic less than 10μg / L, run at a filtration rate of 3m / h until the concentration of iron in the effluent is less than 0.3mg / L, the concentration of manganese is less than 0.1mg / L, and the concentration of arsenic is less than 10μg / L, and run at a filtration rate of 4m / h until the concentration of iron in the effluent is less than 0.3mg / L, manganese concentration less than 0.1mg / L, ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com