Composite pressure sensor and preparation method thereof

A technology of pressure sensor and white carbon black, which is applied in the field of composite pressure sensor and its preparation, can solve the problems that need to be improved, and achieve the effects of excellent structure control effect, low price, energy saving and environmental protection in the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

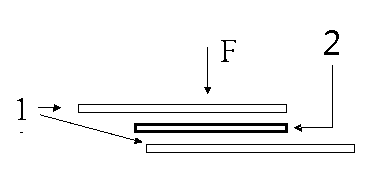

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in combination with specific embodiments.

[0021] In the following specific embodiments, the one-component RTV silicone rubber is the D09 type silicone rubber of Jiahang Rubber Industry; the white carbon black is nano-scale silica with a particle size of 1200 mesh; The conductive carbon black of 40B2 has a particle size of 23nm. The mass ratio of one-component RTV silicone rubber, white carbon black and conductive carbon black is 3.8: (0.8-1): (5-6).

[0022] The specific preparation process of the composite pressure sensor of the present invention is as follows:

[0023] (1) Use an electronic balance to weigh one-component room temperature vulcanized silicone rubber, white carbon black, conductive carbon black and acetone in proportion, put the acetone into a beaker, and put the weighed one-component room temperature vulcanized silicone rubber, white carbon Black and conductive carbon black were added to acetone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com